Linear Tech. makes a good part, the part number is LT3791......

http://www.linear.com/product/LT3791

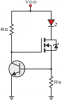

I have used this for many LED designs, full PWM control and a ton of power output for such a small part, don't use a 555 timer at 500KHz. Just build a discrete driver circuit.

Can you specify the details of exactly what you are trying to drive.... Voltage, current, and dimming requirements?

CREE also makes and LMD300 LED driver that outputs 40V @ 900mA constant current source with 0-100% dimming. They are meant to be paired with CREE's LMH2 LED module, but I would assume it could be used on anything.

There are much better ways to acheive optimal results than using a 1970's IC and a fet and transistor. Check out the datasheet on both the LMD300 or the LT3791.

I am an electrical engineer and work with LED lighting systems everyday and the driver circuitry associated, kind of my area of expertise.