Dayyummm..., QK!!

knoooows his shhit...lol

Exactly what Qk said...hehe.

This chart is old, like 2009 old ..

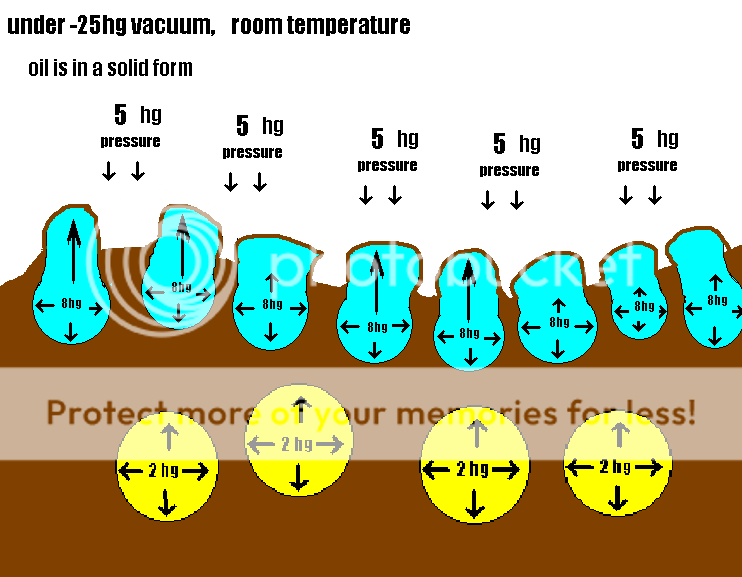

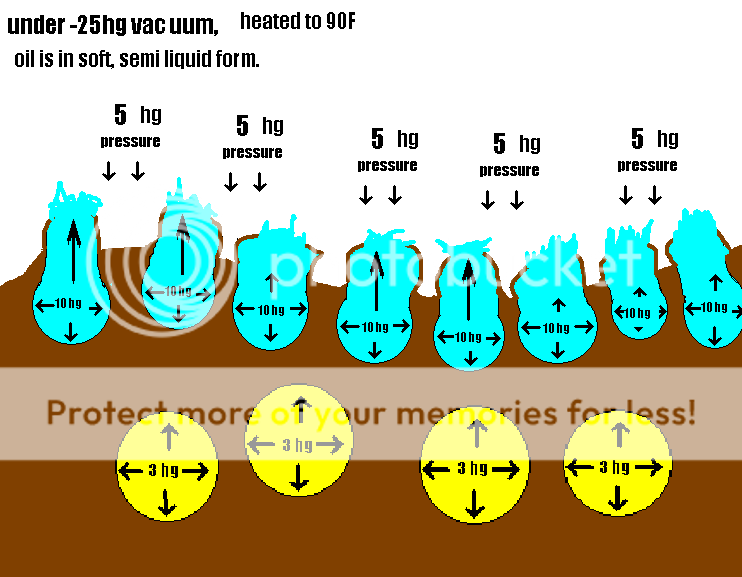

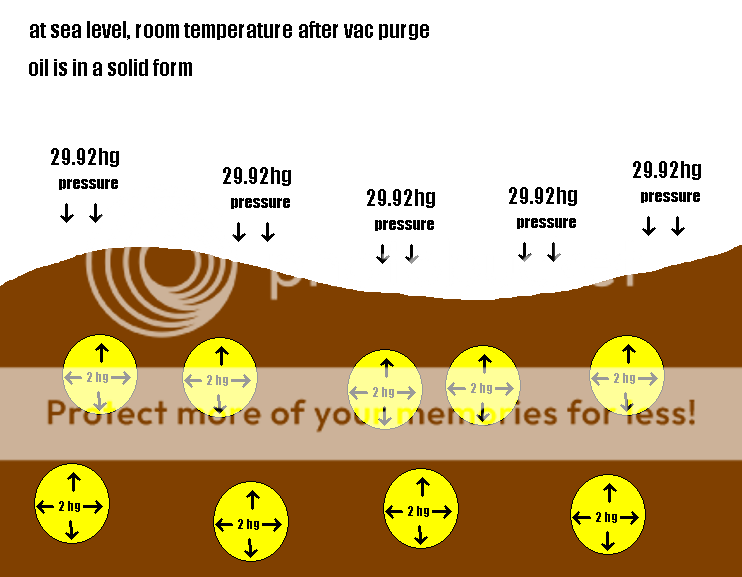

But, the same principle applies, at sea level... A vac of-25hg in very thin film is efficient enough to purge away the butane molecules.

As QK pointed out...think more on the final purge, near the end of the process..

All the heavier poly-terpenes remain in the oleoresin, while altering the atmospheric pressure and letting the matrix loosen up a bit for the gas desperately trying to flee the oleoresin.

The -25 hg reference is dated, as many oil makers back then used brake-bleeding pumps, Pump n Seal...

The pioneers of our beloved Bho, had done so many hands on runs...

I mean, these guys, would do runs every single day, and document everything, and were kind enough to post the experience.

This was long before the BHO movement per se was even initiated.

But, yeas...

@Guzias.. You need bigger glass collection dish, you know this man...thin for the win!

Or...Gawd, I know with the amount you run...this would suck ass but maybe split your runs up...

Half in one dish and the other half in separate dish.

Perhaps more work, but perhaps much quicker as your oil is sooooo skinny now?

Just a thought..

I've personally have never really ran a vac for longer than about an hour..

Unless of course,, we are going for comb or some fine wax.