C.O.B.S.S.L. News and Articles

- Thread starter stardustsailor

- Start date

SupraSPL

Well-Known Member

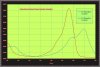

Not sure if you have seen this AP, but what this graph is showing is actually even worse in practice because we have access to top bin 3000K 80 CRi but no access to any high bin high CRi COBs. Although the high CRi or 2700K COBs may have a better spectrum than the 3000K 80 CRi, you can see the sacrifice that is made to achieve that, it has been described as putting a filter over a 3000K 80 CRi, many fewer photons are lost. If you are interested in a better spectrum than the 3000K 80 CRi alone, a very good approach may be to supplement with 660nm Cree photo reds which are over 42% efficient and could add a large 660nm spike to this graph with no efficiency sacrifice. You could even widen the 660 spike by mixing photo reds of 650, 660 and 670nm.Based on the diagrams, I would choose the CRI 93 (3k) but after comparing the four analyses, I'd have to ask you for insight.

With the 93 CRI, you get less green and more blue and infrared (~3-5%), which is good in my book. Also, the 93 CRI peaks at 630nm, while the 80CRI spikes around 600nm. However, the different estimates lead me to believe that the 80 CRI performs at a higher efficiency, thus begs the question: what do you make of all of this?

Last edited:

FranJan

Well-Known Member

SDS we need a hybrid. It's the only way we are gonna get the high CRI, broader peaks that growers want from our "whites". There's so many blends companies are using with COBs we're never going to know what blend works best until we build our own grower centric white. At least that's how I'm looking at it nowadays. I'm telling you guyz, COBs are dead  .

.

http://news4led.blogspot.fr/2014/03/design-approaches-for-high-cri-leds.html?m=1

Design Approaches for High-CRI LEDs

Ninety-CRI LEDs have been about 20% less efficient than 80-CRI, limiting adoption. Here are two approaches to closing that gap.

White LEDs are typically fabricated by combining blue LEDs with yellow, green, and red phosphors. Historically, cool white LEDs were the first to reach the market, for applications in which high CRI was not a requirement. These LEDs were made with only yellow phosphors and had a bluish-white tinge, in the CCT range of 5,000 to 6,500 K. As illumination applications became more prevalent, LEDs with a warmer white appearance in the CCT range of 2,700 to 4,000 K became available. These warm white LEDs used a combination of yellow and red phosphors to achieve the desired CCT and minimum 80 CRI but with an efficiency penalty when compared to the cool white LEDs.

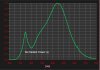

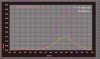

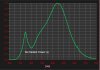

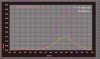

Figure 1. Lumen loss of current red phosphors in warm white LEDs

Figure 1 shows the spectrum for a typical 2,700 K, 80-CRI white LED (green line) and the human photopic response (blue dashed line). Although the addition of conventional red phosphors enables warmer CCTs and higher CRI than yellow phosphors alone, there is significant lumen loss since much of the red phosphor emission occurs outside the human eye's sensitivity. To make a 90-CRI LED, the typical approach is to use an even redder phosphor to reach the higher CRI, but with even less emission in the eye's sensitive region. As a result, a 90-CRI LED at 100 lm/W is about 20% less efficient than an equivalent 80-CRI LED.

One approach to improve the efficiency of the 90-CRI LED is to focus on phosphor improvements such as the introduction of a narrow (< 50nm FWHM) red phosphor. Figure 1 also shows the modeled spectra of a 2,700 K, 90-CRI white LED (red line) that includes a narrow (30 nm FWHM) red phosphor. The narrower red phosphor increases the lumen efficiency by substantially reducing the emission outside the eye's sensitivity range. By optimizing the material quality, the wavelength peak, and the width of the red phosphor's emission, up to 20% gains in LED efficiency may be achieved.1 This approach is expected to benefit all L1 LEDs including single emitters such as LUXEON TX, LUXEON 3535L, or LUXEON COB.

Another approach is the to use direct red LEDs in combination with white LEDs to create a hybrid LED module with high efficiency and high CRI. A direct red LED has a significantly narrower emission than a red phosphor, leading to a similar reduction to the lumen loss shown in Figure 1. In 2013, as part of a DOE SSL Product Development project, a hybrid LED module was demonstrated by Philips Lumileds with 712 lm, 140 lm/W, CRI = 91, and R9 = 75 operating at 85°C.2 The direct red wavelength (610 to 615 nm) was selected for optimal efficiency and R9 impact, and an off-white LED was used to provide the green part of the spectrum. The combination of red and white LEDs does result in more complicated system designs, but it can provide the added benefit of color tunability or integrated color control.

Approaches for efficient 90-CRI LEDs

High-CRI technology

Examples

Typical specs at 85°C

High-CRI phosphor

Luxeon TX, MP 3535L, COB

95–100 lm/W, CRI = 95, R9 = 80

Direct red and off-white

Hybrid LED for DOE SSL Product Development project

140 lm/W, CRI = 91, R9 = 76

References

http://news4led.blogspot.fr/2014/03/design-approaches-for-high-cri-leds.html?m=1

Design Approaches for High-CRI LEDs

Ninety-CRI LEDs have been about 20% less efficient than 80-CRI, limiting adoption. Here are two approaches to closing that gap.

White LEDs are typically fabricated by combining blue LEDs with yellow, green, and red phosphors. Historically, cool white LEDs were the first to reach the market, for applications in which high CRI was not a requirement. These LEDs were made with only yellow phosphors and had a bluish-white tinge, in the CCT range of 5,000 to 6,500 K. As illumination applications became more prevalent, LEDs with a warmer white appearance in the CCT range of 2,700 to 4,000 K became available. These warm white LEDs used a combination of yellow and red phosphors to achieve the desired CCT and minimum 80 CRI but with an efficiency penalty when compared to the cool white LEDs.

Figure 1. Lumen loss of current red phosphors in warm white LEDs

Figure 1 shows the spectrum for a typical 2,700 K, 80-CRI white LED (green line) and the human photopic response (blue dashed line). Although the addition of conventional red phosphors enables warmer CCTs and higher CRI than yellow phosphors alone, there is significant lumen loss since much of the red phosphor emission occurs outside the human eye's sensitivity. To make a 90-CRI LED, the typical approach is to use an even redder phosphor to reach the higher CRI, but with even less emission in the eye's sensitive region. As a result, a 90-CRI LED at 100 lm/W is about 20% less efficient than an equivalent 80-CRI LED.

One approach to improve the efficiency of the 90-CRI LED is to focus on phosphor improvements such as the introduction of a narrow (< 50nm FWHM) red phosphor. Figure 1 also shows the modeled spectra of a 2,700 K, 90-CRI white LED (red line) that includes a narrow (30 nm FWHM) red phosphor. The narrower red phosphor increases the lumen efficiency by substantially reducing the emission outside the eye's sensitivity range. By optimizing the material quality, the wavelength peak, and the width of the red phosphor's emission, up to 20% gains in LED efficiency may be achieved.1 This approach is expected to benefit all L1 LEDs including single emitters such as LUXEON TX, LUXEON 3535L, or LUXEON COB.

Another approach is the to use direct red LEDs in combination with white LEDs to create a hybrid LED module with high efficiency and high CRI. A direct red LED has a significantly narrower emission than a red phosphor, leading to a similar reduction to the lumen loss shown in Figure 1. In 2013, as part of a DOE SSL Product Development project, a hybrid LED module was demonstrated by Philips Lumileds with 712 lm, 140 lm/W, CRI = 91, and R9 = 75 operating at 85°C.2 The direct red wavelength (610 to 615 nm) was selected for optimal efficiency and R9 impact, and an off-white LED was used to provide the green part of the spectrum. The combination of red and white LEDs does result in more complicated system designs, but it can provide the added benefit of color tunability or integrated color control.

Approaches for efficient 90-CRI LEDs

High-CRI technology

Examples

Typical specs at 85°C

High-CRI phosphor

Luxeon TX, MP 3535L, COB

95–100 lm/W, CRI = 95, R9 = 80

- Simple configuration

- Narrow red phosphor improves efficiency

- Large efficiency penalty w/ conventional red phosphors

Direct red and off-white

Hybrid LED for DOE SSL Product Development project

140 lm/W, CRI = 91, R9 = 76

- High efficiency w/ high CRI

- Color tunable

- High LED and system cost

References

- O. Shchekin, J. Bhardwaj, "LED technologies for Breakthrough in performance and cost," China SSL 2012

- G. Huang, W. Soer, G. Vu, F. Jin, "High Power Hybrid Warm White LEDs for Illumination," poster presented at DOE SSL R&D Workshop, Tampa, FL (2014)

stardustsailor

Well-Known Member

Not sure if you have seen this AP, but what this graph is showing is actually even worse in practice because we have access to top bin 3000K 80 CRi but no access to any high bin high CRi COBs. Although the high CRi or 2700K COBs may have a better spectrum than the 3000K 80 CRi, you can see the sacrifice that is made to achieve that, it has been described as putting a filter over a 3000K 80 CRi, many fewer photons are lost. If you are interested in a better spectrum than the 3000K 80 CRi alone, a very good approach may be to supplement with 660nm Cree photo reds which are over 42% efficient and could add a large 660nm spike to this graph with no efficiency sacrifice. You could even widen the 660 spike by mixing photo reds of 650, 660 and 670nm.

Dear Supra,

Indeed ,in most points ,I 've to agree with you .

Please allow me ,though to express some points ,which might be of further "debating ".

Thus researching & testing .

1) Well for starters ,a point that I kinda disagree with you :

" Although the high CRi or 2700K COBs may have a better spectrum than the 3000K 80 CRi "

Allow me ,to trust that actually is the other way around ,the opposite .

-The irradiance spectrum to which plants are exposed during growth has specific effects on different types of plant responses such as photosynthesis, photomorphogenesis, phototropism, and photonasty.

-For instance, spectra enhancing the photosynthetic capacity of leaves per unit leaf area do not necessarily enhance a whole plant morphology which is favourable for light interception and therefore also do not necessarily enhance plant production.

(keep that phrase in mind also,when attempting to mix monos with COBS)

http://jxb.oxfordjournals.org/content/61/5/1267.full

A high CRI 3000°K COB ,is not as 'efficient' in light- quality terms also-not just in power terms-,

as a 80 CRI one, to bring a plant of Cannabis species from the start of its life cycle till the end ,

close to its max genetic potentional .

(Express the 'best' phenotype out of the genotype ,

where 'best' stands for the sum of favourable physiological

and biochemical attributes -characteristics expressed and

the degree of expression.)

2) 2700K leds differ from 3000K ones only in (of same type ) phosphor load.

Different CRI 2700 & 3000K CCTs ,use different phosphor types .

I.e .( Random values ,just for comparison )

3000K 80 CRI : Blend of 25% Green silicate phosphor & 75% Amber silicate phosphor .

Total phosphor content : 100mg /sq. cm of LES

2700K 80 CRI : Blend of 25% Green silicate phosphor & 75% Amber silicate phosphor .(same as above )

Total phosphor content : 130mg /sq. cm of LES

3000K 95 CRI :Blend of 30% Green silicate phosphor & 70% Red nitride phosphor .

Total phosphor content : 100mg /sq. cm of LES

2700K 95 CRI :Blend of 30% Green silicate phosphor & 70% Red nitride phosphor .

Total phosphor content : 130mg /sq. cm of LES

So,actually 2700 & 3000K of same CRI series ,differ mainly (spectrum wise ) on the amount of blue wls

they output.2700K output less blue excitation wls and a tad more the phosphor emitted wls ,than 3000K.

And to the final part.

My doubts or concerns about mixing reds & deep reds with the CXA 3000K 80 CRI warm white light ...

A ) BLUE BAND concerns:

Band power distribution :

400-499 nm : 10.6%

500-599 nm : 41.37 %

600-699 nm : 43.71 %

700-780 nm : 4.3%

" Only 7% blue light was sufficient to prevent any overt dysfunctional photosynthesis, which can be considered a qualitatively blue light effect.

(...)

Above 15% blue, the parameters Amax, LMA, Chl content, photosynthetic N use efficiency, and the Chl:N ratio had a comparable relationship as reported for leaf responses to irradiance intensity. It is concluded that blue light during growth is qualitatively required for normal photosynthetic functioning and quantitatively mediates leaf responses resembling those to irradiance intensity."

http://www.ncbi.nlm.nih.gov/pmc/articles/PMC2892149/

Adding reds-deep reds ,will alter (decrease) the 10.6 % ,which is pretty close to 7% .

Not good during vegetative growth,at least.To compensate a red led enhancing ,

blue leds might have to be used.

Blue leds might force leaves (locally -directly underneath mostly )to react ,

as of high irradiance .

(photonasty => Steep leaf angle.Leafs erect towards to the stem attached to ,

to decrease their irradiated lamina surface .Not good ! )

B ) Photobiology concerns :

-PPE ( PPS )= 0.659

( Already ~ 66 % Pfr to turn into Pr ,during 12 hours of darkness )

Adding reds -deep reds will increase that number .

The results of a really high PPS light source ( > .7 ) ,

on Cannabis species ,so far are somewhat discouraging(way prolonged flowering duration).

It effects reproductive stage duration and maturing process .

Prolonged flowering periods do not mean increased yields ,necessarily .

( Depends of PS rates & overall daily PS 'yield' )

FR leds might need to be used also ,to lower the PPS .

Side note : FR leds are famous for their extra-low efficiency .

Last edited:

stardustsailor

Well-Known Member

SDS we need a hybrid. It's the only way we are gonna get the high CRI, broader peaks that growers want from our "whites". There's so many blends companies are using with COBs we're never going to know what blend works best until we build our own grower centric white. At least that's how I'm looking at it nowadays. I'm telling you guyz, COBs are dead.

http://news4led.blogspot.fr/2014/03/design-approaches-for-high-cri-leds.html?m=1

Design Approaches for High-CRI LEDs

Ninety-CRI LEDs have been about 20% less efficient than 80-CRI, limiting adoption. Here are two approaches to closing that gap.

White LEDs are typically fabricated by combining blue LEDs with yellow, green, and red phosphors. Historically, cool white LEDs were the first to reach the market, for applications in which high CRI was not a requirement. These LEDs were made with only yellow phosphors and had a bluish-white tinge, in the CCT range of 5,000 to 6,500 K. As illumination applications became more prevalent, LEDs with a warmer white appearance in the CCT range of 2,700 to 4,000 K became available. These warm white LEDs used a combination of yellow and red phosphors to achieve the desired CCT and minimum 80 CRI but with an efficiency penalty when compared to the cool white LEDs.

Figure 1. Lumen loss of current red phosphors in warm white LEDs

Figure 1 shows the spectrum for a typical 2,700 K, 80-CRI white LED (green line) and the human photopic response (blue dashed line). Although the addition of conventional red phosphors enables warmer CCTs and higher CRI than yellow phosphors alone, there is significant lumen loss since much of the red phosphor emission occurs outside the human eye's sensitivity. To make a 90-CRI LED, the typical approach is to use an even redder phosphor to reach the higher CRI, but with even less emission in the eye's sensitive region. As a result, a 90-CRI LED at 100 lm/W is about 20% less efficient than an equivalent 80-CRI LED.

One approach to improve the efficiency of the 90-CRI LED is to focus on phosphor improvements such as the introduction of a narrow (< 50nm FWHM) red phosphor. Figure 1 also shows the modeled spectra of a 2,700 K, 90-CRI white LED (red line) that includes a narrow (30 nm FWHM) red phosphor. The narrower red phosphor increases the lumen efficiency by substantially reducing the emission outside the eye's sensitivity range. By optimizing the material quality, the wavelength peak, and the width of the red phosphor's emission, up to 20% gains in LED efficiency may be achieved.1 This approach is expected to benefit all L1 LEDs including single emitters such as LUXEON TX, LUXEON 3535L, or LUXEON COB.

Another approach is the to use direct red LEDs in combination with white LEDs to create a hybrid LED module with high efficiency and high CRI. A direct red LED has a significantly narrower emission than a red phosphor, leading to a similar reduction to the lumen loss shown in Figure 1. In 2013, as part of a DOE SSL Product Development project, a hybrid LED module was demonstrated by Philips Lumileds with 712 lm, 140 lm/W, CRI = 91, and R9 = 75 operating at 85°C.2 The direct red wavelength (610 to 615 nm) was selected for optimal efficiency and R9 impact, and an off-white LED was used to provide the green part of the spectrum. The combination of red and white LEDs does result in more complicated system designs, but it can provide the added benefit of color tunability or integrated color control.

Approaches for efficient 90-CRI LEDs

High-CRI technology

Examples

Typical specs at 85°C

High-CRI phosphor

Luxeon TX, MP 3535L, COB

95–100 lm/W, CRI = 95, R9 = 80

- Simple configuration

- Narrow red phosphor improves efficiency

- Large efficiency penalty w/ conventional red phosphors

Direct red and off-white

Hybrid LED for DOE SSL Product Development project

140 lm/W, CRI = 91, R9 = 76

The table summarizes these two technical approaches towards enabling high-efficiency and high-CRI LED solutions for solid-state lighting. As these technologies mature, we expect to see increasing adoption of 90-CRI solutions as the color quality benefit begins to exceed the efficiency tradeoff.

- High efficiency w/ high CRI

- Color tunable

- High LED and system cost

References

- O. Shchekin, J. Bhardwaj, "LED technologies for Breakthrough in performance and cost," China SSL 2012

- G. Huang, W. Soer, G. Vu, F. Jin, "High Power Hybrid Warm White LEDs for Illumination," poster presented at DOE SSL R&D Workshop, Tampa, FL (2014)

Some thoughts of mine ...

HIGH CRI is something that really belongs to the "human vision" department of solid state lighting.

In horti applications ,HIGH CRI ,usually is good when ...illuminating various types of flowers ,in a

flowerist's shop .

What we really need ,is a light coming from a powerful enough source ,efficient enough and with prolonged service life.

A light that will have a spectrum (variable or not ) ideal or close to ideal .How " ideal " might be defined ?

Well for starters not any extreme spikes in narrow wls bands ,

as "full" as possible (without severe band gaps ) light ,at least in the 400-750 region ,

Not extreme low or high figures of R:FR , PPS , Pfr : Pf .

A general band power distribution of 10% BL - 35% GR -50% R-DR - 5% FR seems to be working miracles ,also.

Now ...Allow me to express some funny thoughts ...

How we can make white light using the excitation-conversion method (phosphors ) .

Way #1 : Violet excitation source ,green conversion phosphor .Result white light .

No warm or cool hues here.Altering the ratio of excitation light escaping vs emitted light from conversion ,

will result in greenish or purplish hues of light .Not good method.

Way #2 : Blue excitation source ,yellow or amber (or green+red,or green+amber ) conversion phosphor .Result white light .

Warm ,neutral and cool tones can be achieved (bluish or yelloish tones ).We know plenty about this method,so far and

we keep learning ...

Way #3 : Cyan excitation source ,red-deep red phosphors . Result white light .

WoW! The cyan wl band that is missing from most grow lights !

A very 'neglected' band,that if you search a tad is very-very important in plenty of aspects ,for plant growth..

And the very much wanted reds for the bud-leaves (the last to unfold) ,which swell the neighbouring flower buds !

But that tech does not exist !

Oh,how nice would be to mix COBs using this way ,with some 'ordinary' ones ..(Way #2 ones ..)

Blue dies + green& amber phosphors ( like on CXA3070 3000K 80 CRI

Cyan dies + red/deep red phosphors (like on the ones that you imagine,right now ! )

Side note : Osram I think ,had made some modules (discontinued product probably)

utilising a special type of very efficient Cyan PC leds

(blue die excitation +green phosphor ) along with 630 reds (..or was it 645/660 nm ones ? ),in

order to produce a high cri light !

Cheers.

stardustsailor

Well-Known Member

LED Analysis Note

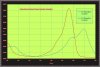

Some details about photobiological LED light measurements :

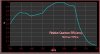

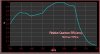

R:FR (660:730)

This parameter of the light source ,expresses the radiometric power ratio between red light 660 nm and

far red light of 730 nm .It is calculated at a spreadsheet following that rule :

R: FR =

PPF of light source 10 nm band centered on 660 nm / PPFof light source in 10 nm band centered on 730 nm

http://www.google.gr/url?sa=t&rct=j&q=&esrc=s&source=web&cd=5&ved=0CD4QFjAE&url=http://xa.yimg.com/kq/groups/21666630/1659117910/name/17-Phytochrome-and-Light-development.pdf&ei=rQpNVJOBCobiaKbfgKAP&usg=AFQjCNEc7nfhb27yio_P7r6YBXSJdnYoiQ&bvm=bv.77880786,d.d2s

It is a very usefull parameter to predict the internodal stretching ,compactness & height and many other photomorphogenic charateristics of the light source ,that the plants will be forced to express .

----------------------------------------------------------------------------------------------------------------------------------------------------------

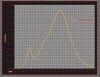

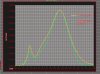

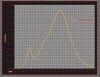

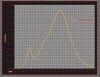

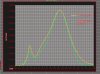

PPE ( PPS )

The Phytochrome Photo Equilibrium or Phytochrome Photostationary State a light source ,

will bring to, the plants irradiated .

A parameter of pretty high importance .

It should not be more than .7 - .72 ,neither lower of .65,for a natural circadian cycle.

In order to calculate the PPS of a light source ,firstly two separate spectrums have to be obtained .

The Pfr action spectrum of the light source anf the Pr action spectra of the light source.

This is done by :

1) Turning the relative power spectral distribution function (graph ) of the source into

a Mean (absolute) power spectral distribution function.

2) The Mean (absolute) power spectral distribution is multiplied with the linear

λ/ 119,708 function ,

and the result is the Mean Quanta spectral distribution function of the light source..

3) Then the Mean Quanta spectral distribution function is weighted with each of the two types of Phytochrome Pfr & Pf Quanta absorption ( action spectra) spectral distribution function.

Two excitation action spectrums are the result.One for Pfr and one for Pr.

4) Then PPS is calculated as :

PPS = Pfr excitation Total Flux / ( Pfr excitation Tot. flux + Pr excitation Tot. flux )

Note* : Blue wls effect on Phy , are calculated ,with this way .

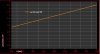

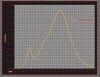

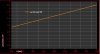

-YPF / PPF

YPF = PPF* RQE

As in :

PPF

x

RQE Mc 1982.

Then :

YPF / PPF (green line :yellow line )

Higher values for this ratio indicate a better plant growth ,

than the PPF as measured by a standard *quantum sensor

(* not McCree RQE or DIN 5301-10 weighted ).

(Cree CXA 3000K 80 cri graphs-functions used in examples)

Some details about photobiological LED light measurements :

R:FR (660:730)

This parameter of the light source ,expresses the radiometric power ratio between red light 660 nm and

far red light of 730 nm .It is calculated at a spreadsheet following that rule :

R: FR =

PPF of light source 10 nm band centered on 660 nm / PPFof light source in 10 nm band centered on 730 nm

http://www.google.gr/url?sa=t&rct=j&q=&esrc=s&source=web&cd=5&ved=0CD4QFjAE&url=http://xa.yimg.com/kq/groups/21666630/1659117910/name/17-Phytochrome-and-Light-development.pdf&ei=rQpNVJOBCobiaKbfgKAP&usg=AFQjCNEc7nfhb27yio_P7r6YBXSJdnYoiQ&bvm=bv.77880786,d.d2s

It is a very usefull parameter to predict the internodal stretching ,compactness & height and many other photomorphogenic charateristics of the light source ,that the plants will be forced to express .

----------------------------------------------------------------------------------------------------------------------------------------------------------

PPE ( PPS )

The Phytochrome Photo Equilibrium or Phytochrome Photostationary State a light source ,

will bring to, the plants irradiated .

A parameter of pretty high importance .

It should not be more than .7 - .72 ,neither lower of .65,for a natural circadian cycle.

In order to calculate the PPS of a light source ,firstly two separate spectrums have to be obtained .

The Pfr action spectrum of the light source anf the Pr action spectra of the light source.

This is done by :

1) Turning the relative power spectral distribution function (graph ) of the source into

a Mean (absolute) power spectral distribution function.

2) The Mean (absolute) power spectral distribution is multiplied with the linear

λ/ 119,708 function ,

and the result is the Mean Quanta spectral distribution function of the light source..

3) Then the Mean Quanta spectral distribution function is weighted with each of the two types of Phytochrome Pfr & Pf Quanta absorption ( action spectra) spectral distribution function.

Two excitation action spectrums are the result.One for Pfr and one for Pr.

4) Then PPS is calculated as :

PPS = Pfr excitation Total Flux / ( Pfr excitation Tot. flux + Pr excitation Tot. flux )

Note* : Blue wls effect on Phy , are calculated ,with this way .

-YPF / PPF

YPF = PPF* RQE

As in :

PPF

x

RQE Mc 1982.

Then :

YPF / PPF (green line :yellow line )

Higher values for this ratio indicate a better plant growth ,

than the PPF as measured by a standard *quantum sensor

(* not McCree RQE or DIN 5301-10 weighted ).

(Cree CXA 3000K 80 cri graphs-functions used in examples)

Last edited:

AquariusPanta

Well-Known Member

Deep stuff Star.

You lost me somewhere in the graphs.

You lost me somewhere in the graphs.

AquariusPanta

Well-Known Member

I didn't initially see that but good point to mention. It appears we have the technology, publicly, to replicate a good portion of the vegetative states for plants*, with the exception of "mono" UV and (IR) stars. I suppose if you had one/tenth the knowledge of StarSailor over this matter, you could come up with a mathematical scheme to mirror the sun's spectral qualities, during the Spring, using specialized monos.Rich info Stardust!

Look at the Cool LED numbers compared to the sun numbers in the visible percentages. Almost a perfect match.

As far as the lab report from Utah State University goes, I don't know what LED's they used or if they instead took the best LED numbers from a popular source and just slapped down the ideal spectrum projections; who knows.

Ultimately, computer engineers seem to be absent from the LED growing scene. I point this out because I have yet to see any *smart* LED light fixtures; those that can function to a programmed weather pattern or environment. Although lights, to some individuals, may seem to be just a source of lighting for visual enhancement, to us dedicated growers, they are sources to an art. Our canvas is limited to the plants that we grow and the light that we choose dictates which colors we paint with.

The ideal indoor growing light, clearly demonstrated in the lab report, is the Sun itself. When you think about what we now have, in respect to lighting, we are as close as we are far from replicating what makes our Sun the ideal lighting source. Not only have we yet to master copying the wonderful lighting attributes of the Sun, we have yet to fully incorporate the various factors that are natural to the environment into our indoor grow spaces. Sure, we have machines that generate wind, create humidity, or dehumidify, but we haven't collectively reached a level of arete or excellence in our crafting endeavors.

You may be thinking to yourself at this moment, where am I going with all of this. Simple, we will eventually need our electrical engineers to mingle with their fellow constituents (computer engineers/programmers) in order to produce lighting fixtures that go beyond the scope of flipping a switch to turn it on/off or to use a separate timing device in order to control senses.

I'm of course briefly outlining the future of horticulture/agriculture and basically what will be needed in Space, if we ever get to that point, in order for us to feed ourselves under non-ideal growing environments.

Who knows, maybe one or a group of us bloggers here will bring us that much closer to the ideal.

Last edited:

AquariusPanta

Well-Known Member

Not sure if you have seen this AP, but what this graph is showing is actually even worse in practice because we have access to top bin 3000K 80 CRi but no access to any high bin high CRi COBs.

Wait, we as in you and I or you and the other well-established wizards here on Rolling? I'm under the impression that the public sources that offer COB's, such as Mouser and DigiKey, use random bin but please further inform me of any possible misunderstanding(s); my experience with COBs can only be traced to my Vero 18's (from DigiKey).

If you asked me whether more or less available phosphor on a given COB was good, I'd be found dumbfounded2700K leds differ from 3000K ones only in (of same type ) phosphor load.

Different CRI 2700 & 3000K CCTs ,use different phosphor types .

I.e .( Random values ,just for comparison )

3000K 80 CRI : Blend of 25% Green silicate phosphor & 75% Amber silicate phosphor .

Total phosphor content : 100mg /sq. cm of LES

2700K 80 CRI : Blend of 25% Green silicate phosphor & 75% Amber silicate phosphor .(same as above )

Total phosphor content : 130mg /sq. cm of LES

3000K 95 CRI :Blend of 30% Green silicate phosphor & 70% Red nitride phosphor .

Total phosphor content : 100mg /sq. cm of LES

2700K 95 CRI :Blend of 30% Green silicate phosphor & 70% Red nitride phosphor .

Total phosphor content : 130mg /sq. cm of LES

So,actually 2700 & 3000K of same CRI series ,differ mainly (spectrum wise ) on the amount of blue wls

they output.2700K output less blue excitation wls and a tad more the phosphor emitted wls ,than 3000K.

.

.Please share with me your understanding of this matter SDSailor.

Last edited:

SupraSPL

Well-Known Member

As of just a dew days ago, we were able to buy 20 packs of the CXA3070 3000K AB bin from Arrow. Unfortunately they just sold out and now all we have is the Z2 bin from Digikey or the Z2 bin in 20 packs from Arrow. However, there may be a few RIU members that have access to the AB bins but I am not sure what is currently available. Hopefully more ABs will become available for a fair price.

More phosphor tends to lead to lower efficiency. The phosphor is converting blue into white, and that is not a 100% efficient process (Stokes losses) The further we go in the "warm" direction, the greater the losses because we are moving further away from blue. That is why it is more efficient to supplement warm whites with deep reds rather than using high CRI to get more red. In other words, using a blue LED to make a high CRI warm white LED is kind of a fools errand, but it is what we have to work with at the moment.

You can take that line of thinking a step further and use cool whites and supplement with reds and deep reds, but in the case of the CXA3070, our warm whire were actually more efficienct than the cool whites because of the bin selection at the time. Also, the cool whites are dominant in the yellow/green range rather than the red range, which may have some undesirable photomorphogenic effects during the flowering phase (slower maturation, fluffier buds/leafier buds/foxtailing?)

More phosphor tends to lead to lower efficiency. The phosphor is converting blue into white, and that is not a 100% efficient process (Stokes losses) The further we go in the "warm" direction, the greater the losses because we are moving further away from blue. That is why it is more efficient to supplement warm whites with deep reds rather than using high CRI to get more red. In other words, using a blue LED to make a high CRI warm white LED is kind of a fools errand, but it is what we have to work with at the moment.

You can take that line of thinking a step further and use cool whites and supplement with reds and deep reds, but in the case of the CXA3070, our warm whire were actually more efficienct than the cool whites because of the bin selection at the time. Also, the cool whites are dominant in the yellow/green range rather than the red range, which may have some undesirable photomorphogenic effects during the flowering phase (slower maturation, fluffier buds/leafier buds/foxtailing?)

Last edited:

SupraSPL

Well-Known Member

Also, I am in the camp that it is not the high-CRI status that we growers should be chasing after, it is the increase in deep red. Yes it is true that the sun is high CRI, but it is the intensity of the sun that is so useful for growing not its CRi (incandescent bulbs are 100 CRi). My patients and friends prefer indoor organic bud (grown with low CRI) over outdoor bud because the indoor bud is dense and the outdoor bud tends to be leafy.

Moral of the story, I believe it is better to supplement 80CRi warm whites with high efficiency deep reds than to use high CRi whites. Maybe we will see this done in a single COB like the striped or combo COBs shown earlier.

Moral of the story, I believe it is better to supplement 80CRi warm whites with high efficiency deep reds than to use high CRi whites. Maybe we will see this done in a single COB like the striped or combo COBs shown earlier.

SupraSPL

Well-Known Member

" Although the high CRi or 2700K COBs may have a better spectrum than the 3000K 80 CRi "

Regarding the high CRi 2700K and 3000K, the graphs I have seen show a significant peak wavelength shift toward deep red. But regarding 2700K 80 CRi, I see your point and it is a good one. Unfortunately I rarely get to see 2700K graphs compared to 3000K and I have always wondered why they are not included. My assumption was that 2700K has a slightly longer wavelength peak into the red, but if they are simply sacrificing some of the blue for more of the same exact phosphor, the peak would not shift, which would make 2700 K 80 CRi flat out inferior to 3000K 80 CRi. I will have to explore that issue further thank you for pointing it out.a point that I kinda disagree with you...actually is the other way around ,the opposite...actually 2700 & 3000K of same CRI series ,differ mainly (spectrum wise ) on the amount of blue wls

they output

I absolutley agree. When I supplement with deep reds I add blues as well to maintain the blue ratio. I did not mention that in my post because I am trying to be concise but it is a very important point for new DIYers to understand. The blue ratio is very important during flowering. For starters and very noticeable, insufficient blue decreases frosting, flavor and potency. It will also affect stretch and internode distance.My doubts or concerns about mixing reds & deep reds with the CXA 3000K 80 CRI warm white light ...Adding reds-deep reds ,will alter (decrease) the 10.6 % ,which is pretty close to 7% .

Not good during vegetative growth,at least.To compensate a red led enhancing ,blue leds might have to be used.

Here is what I have noticed so far in in practice. Switching from HPS to LEDs resulted in a noticeable decrease in flowering time and a cleaner finish. Maybe it is due to cooler canopy temps, maybe it is due to the infrared glow of large heatsinks cooling off after lights out. Maybe it is both, but in my experience, canopy temps and maybe even night time temp is much more important when it comes to flowering duration.Adding reds -deep reds will (affect deep red/far red ratio, possibly causing) prolonged flowering duration...reproductive stage duration and maturing process .

Prolonged flowering periods do not mean increased yields ,necessarily .

When I added red/deep red/blue LEDs to the warm white COBS, I also noticed a shorter flowering duration. I ran a room with almost entirely 3000K warm white 80CRi during the summer the canopy temps were slightly elevated and I noticed a longer flowering duration, increase in yield and slight decrease in resin quality. Then I added a bunch of blues/deep reds and ran the room again, with slightly cooler canopy temps and the ladies finished on time and much better outcome (slightly decreased yield, better quality resin and buds). As you know I run and re-run some genos over and over so I can notice when they are expressing different phenos.

Last edited:

AquariusPanta

Well-Known Member

So I take it that Z2 bin, from either DigiKey or Mouser, is the common, average grade quality whereas AB bin is like the top selection, the cat's meow as one of my old but whimsical professors would say, yes?As of just a dew days ago, we were able to buy 20 packs of the CXA3070 3000K AB bin from Arrow. Unfortunately they just sold out and now all we have is the Z2 bin from Digikey or the Z2 bin in 20 packs from Arrow. However, there may be a few RIU members that have access to the AB bins but I am not sure what is currently available. Hopefully more ABs will become available for a fair price.

I did find Arrow and their LED database/selection after you mentioned them, but all I could find was Z2 like you said. Is there anything between Z2 and AB as for quality or are those the two markers? Also, from your experience, how often do these AB bin COBs come into public circulation?

Great posts by the way, dey coherent!

PSUAGRO.

Well-Known Member

I agree.............with some "tweaking" they could be the best WW cob on the market........if the egg stays sunny-side upThose Alta leds have pretty impressive numbers. They may be in my future.

Mechmike

Well-Known Member

267 lumens/watt @93-95 cri is very impressive indeed. If this is for real they could become the leader in horticultural led tech.I agree.............with some "tweaking" they could be the best WW cob on the market........if the egg stays sunny-side up

stardustsailor

Well-Known Member

Well ,due to shortage of time ...That is why it is more efficient to supplement warm whites with deep reds rather than using high CRI to get more red. In other words, using a blue LED to make a high CRI warm white LED is kind of a fools errand, but it is what we have to work with at the moment.

You can take that line of thinking a step further and use cool whites and supplement with reds and deep reds, but in the case of the CXA3070, our warm whire were actually more efficienct than the cool whites because of the bin selection at the time. Also, the cool whites are dominant in the yellow/green range rather than the red range, which may have some undesirable photomorphogenic effects during the flowering phase (slower maturation, fluffier buds/leafier buds/foxtailing?)

Very quick ...And many will be left to search ...

" more efficient to supplement warm whites with deep reds rather than using high CRI to get more red."

Efficient (energy-wise ) yes ,by all means.Growth efficient ? Photomorphogenic favourable light ?

Hmmm....

Deep reds ,will increase that nice PPE of ~ .066 (close to natural sunlights photomorphogenic / circadian light .7-.72 ),

way up ,close to .8 ....

That will prolong the flowering time ,but most importantly ,the Sativa *dom cultivars ,will be very prone to form staminate flowers (if " bothered" even slightly by dark interruption or even substrate pH / E.C. fluctuations<=quite rare,but it happens ).

*plants that already 'struggle' to turn sunlight's 72% Pfr ,into x% Pr needed to

form a "flowering" signal, within a tad more 12 hours of darkness.( 11 hours is min day-light duration at 21 Dec,to the latitudes 30N and 30 S ,where the Sativas are naturally grown . ).

A light that turns more than 72% of Phy into the Pfr form ,will/may cause "trouble" to the Sativa dom plants.

Adding blues( especially over 10%-15% of tot. rad. power .Caution in selecting-placing . )

will make things worse in the already prolonged flowering .

Foxtailing is almost a sure thing . Many small bud clusters will be still immature ,

even though the majority of the buds will be at the end of harvesting window time ...

Blue /cyan wls 'enhance/support' protein biosynthesis.Thus also the increased Mg -N -P assimilation .

Blue light kinda 'preserves' the 'vegetative growth mode ',even at late flowering stage ...

New flower clusters are formed ,on top of the maturing/already mature ones !

FR leds have to be added . To lower the PPS .

Since deep red and blues are used ,that means that the plants is receiving signals of high irradiation .

And that's true to a point .Blues and reds ,are where both chlorophylls are peaking in absorptance.

So only the leaves directly irradiated (incident light ) will be ustilising those wls ..

And from them ,only the youngest ones (bud leaves) will be using efficiently the captured photons(<=that's good ).

Still ..That actually happens when buds are formed ..Thus from mid flowering and later ...

Up till then ?

So green and amber leds have to fill the high irradiation "gap" ..

The "signal " is provided by the blue and red wls ...

But the actual 'bread' for the whole plant light capturing is missing ...

Yeap ...FR ,green ,amber leds are of really low to average efficiency ...

Still,they should be added ...

So overall efficiency is going to be held up by blue and red leds ,only to be dropped by the rest that should be added ..

So ..It seems very appealing ,if we get some good bin of high cri ,to provide all those mentioned above ....

And easy to install -drive ,too !

And ,do not forget the most important : From ~ mid flowering and on .Not sooner .(Not good ! )

About Cool whites ,we'll talk further on !

Cheers

Last edited:

SomeGuy

Well-Known Member

I ran a room with almost entirely 3000K warm white 80CRi during the summer the canopy temps were slightly elevated and I noticed a longer flowering duration, increase in yield and slight decrease in resin quality. Then I added a bunch of blues/deep reds and ran the room again, with slightly cooler canopy temps and the ladies finished on time and much better outcome (slightly decreased yield, better quality resin and buds). As you know I run and re-run some genos over and over so I can notice when they are expressing different phenos.

Supra,

This is what I am experiencing right now. longer flowering duration. My resin production seems fine for where they are at right now. I also do NOT have the IR from passive heat sinks. Mine run cool constantly with active cooling. My thoughts are to build two pontoons carrying some far red and far blue on them to supplement the high powered white bars. Also adding a lights out IR source to zap them a bit. It has been my intuition that this would decrease the flower time.

Just throwing in my 2cents as I am currently making these observations in my first led grow.

~SG

Positivity

Well-Known Member

So if I've read this correctly..which isn't that easy..lol.

The 3k spectrum is very close to ideal. Obviously not perfect with somewhat extended flowering and maybe extra stretching.

So all the monos will add considerable challenge in matching the spread, efficiency, and correct spectrum.

So...the best course of action will be multiple type cob sources. 5k, 3k, and 2700k to be turned on at appropriate times.

At least until a cob becomes available with a perfectly tuned spectrum made just for growing.

But then multiple cobs will be an expensive option..double or triple the price since not all will be run at the same time to get the desired power level.

Hence the "simple" 3k setup until a more appropriate cob comes along. Maybe a broader blue peak including cyan and a little more far red.

I know in my grow room things are progressing towards turning "plain" white. My veg room is there...my spectral research cab will soon be there, and my flower chamber will most probably go all white soon.

All thoughts subject to change... .

.

The 3k spectrum is very close to ideal. Obviously not perfect with somewhat extended flowering and maybe extra stretching.

So all the monos will add considerable challenge in matching the spread, efficiency, and correct spectrum.

So...the best course of action will be multiple type cob sources. 5k, 3k, and 2700k to be turned on at appropriate times.

At least until a cob becomes available with a perfectly tuned spectrum made just for growing.

But then multiple cobs will be an expensive option..double or triple the price since not all will be run at the same time to get the desired power level.

Hence the "simple" 3k setup until a more appropriate cob comes along. Maybe a broader blue peak including cyan and a little more far red.

I know in my grow room things are progressing towards turning "plain" white. My veg room is there...my spectral research cab will soon be there, and my flower chamber will most probably go all white soon.

All thoughts subject to change...