C.O.B.S.S.L. News and Articles

- Thread starter stardustsailor

- Start date

stardustsailor

Well-Known Member

Why It's better to use an array-COB holder ,

even if the cob(s) I use have already holes for screwing down ?

White color on the thermographic pics denotes high temperature

Blue color denotes low temperatures .

Notice the d) case ,how much cooler the cob operates ,

with the combo connector/holder & thermal grease ,as TIM.

Screwing down ,might cause uneven pressure on the COB -heatsink

contacting surfaces.

Let alone to leave the cob as it is ,sucked by the thermal grease's viscosity

or 'securing' with Kapton / alum tape ...

A definite No-No !

For Cree CXA30xx series :

Ideal array holder 50-2234C

http://www.idealind.com/products/oem/led_holders/cree.jsp

http://www.idealind.com/media/pdfs/products/instructions/ND_7868-6_50-21_Instructions.pdf

http://www.idealind.com/media/pdfs/products/specsheets/chip-lok_spec_sheet_combined.pdf

even if the cob(s) I use have already holes for screwing down ?

White color on the thermographic pics denotes high temperature

Blue color denotes low temperatures .

Notice the d) case ,how much cooler the cob operates ,

with the combo connector/holder & thermal grease ,as TIM.

Screwing down ,might cause uneven pressure on the COB -heatsink

contacting surfaces.

Let alone to leave the cob as it is ,sucked by the thermal grease's viscosity

or 'securing' with Kapton / alum tape ...

A definite No-No !

For Cree CXA30xx series :

Ideal array holder 50-2234C

http://www.idealind.com/products/oem/led_holders/cree.jsp

http://www.idealind.com/media/pdfs/products/instructions/ND_7868-6_50-21_Instructions.pdf

http://www.idealind.com/media/pdfs/products/specsheets/chip-lok_spec_sheet_combined.pdf

stardustsailor

Well-Known Member

Cob basics :

Cover/lenses and reflectors may be used to 'accommodate' the output light in cases such as of small or large spaces without any reflective surroundings or high-ceiling / large overhead distances .

A holder/connector is the most preferable/favourable /efficient way of attaching a COB to a heatsink .

Good heatsink preparation and a quality TIM (pref: grease ) will enhance cooling .

Heatsink has to be large enough and or designed appropriate ,to handle the heat generated by the COB(s).

Driver(s) has(-ve) to be of Constant Current (CC ) (dimmable or not )

and they must deliver the appropriate Vo range ,

matching the Vf range of the COB(s) ,in direct relation with Tcase* and If **.-

*Check at COB's technical datasheet for the " Tc vs Vf " graph

**Check at COB's technical datasheet for the " If vs Vf" graph

------------------------------------------------------------------------------------------------------------------------

Add a 12 Volt DC Fan and a Constant Voltage (CV )12 VDC Power Supply Unit (PSU ).,

if you want active cooling ,instead of passive.

Smaller diameter fans of high speed ( i.e. 80 mm / 3200 rpm ) are better suited to pin fin heatsinks or with long-thin fins ,closely placed.

Larger diameter fans of low speed (i.e. 140 mm / 1000 rpm )are better suited to short-thick fins, spaced apart .

Cover/lenses and reflectors may be used to 'accommodate' the output light in cases such as of small or large spaces without any reflective surroundings or high-ceiling / large overhead distances .

A holder/connector is the most preferable/favourable /efficient way of attaching a COB to a heatsink .

Good heatsink preparation and a quality TIM (pref: grease ) will enhance cooling .

Heatsink has to be large enough and or designed appropriate ,to handle the heat generated by the COB(s).

Driver(s) has(-ve) to be of Constant Current (CC ) (dimmable or not )

and they must deliver the appropriate Vo range ,

matching the Vf range of the COB(s) ,in direct relation with Tcase* and If **.-

*Check at COB's technical datasheet for the " Tc vs Vf " graph

**Check at COB's technical datasheet for the " If vs Vf" graph

------------------------------------------------------------------------------------------------------------------------

Add a 12 Volt DC Fan and a Constant Voltage (CV )12 VDC Power Supply Unit (PSU ).,

if you want active cooling ,instead of passive.

Smaller diameter fans of high speed ( i.e. 80 mm / 3200 rpm ) are better suited to pin fin heatsinks or with long-thin fins ,closely placed.

Larger diameter fans of low speed (i.e. 140 mm / 1000 rpm )are better suited to short-thick fins, spaced apart .

Abbrev.:

Xo= Output , i.e. Vo = Output Voltage

Xf= Forward Drop , i.e. Vf =Forward voltage drop of a diode

Xi= Input , i.e. Vi = Input Voltage

Xr= Receiving Signal (for PWM application), i.e. PWMri =PWM receiving signal input pin/wire

Xt =Transmitting Signal , i.e. PWMto = PWM transmitting signal output pin or wire .

Tj= Semiconductor Junction Temperature.

For most COBs : Tj =Tc ( Case Temperature ) =Tsp (Solder Point Temperature )

V=voltage

I=Current

P=Power

T=Temperature

Last edited:

medicinehuman

Well-Known Member

PLASMA LED?http://www.plasmaled.com/diy_led_help.htm

stardustsailor

Well-Known Member

" Feel free to post any News ,Links and Articles ,regarding Cobs/ Led arrays and DIY designing with 'em ! "

Thank You .

stardustsailor

Well-Known Member

" Feel free to post any News ,Links and Articles ,regarding Cobs/ Led arrays and DIY designing with 'em ! "Yeah buddy!

Thank You .

FranJan

Well-Known Member

Sharp Zenigata COBs including Tiger Line

Mega:

http://www.sharpleds.com/megazenigata.html

Mini:

http://www.sharpleds.com/minizenigata.html

Petite:

http://www.sharpleds.com/petitezenigata.html

Tiger - Tunable Dual Driver:

http://www.sharpleds.com/tigerzenigata.html

http://www.sharpsma.com/sites/default/files/Documents/Shared/Web/Downloads/SP_Specification/lighting/tiger-zenigata/GW6TGCBG40C_28Mar13_Spec_DG-132028A.pdf

AquariusPanta

Well-Known Member

O.M.G.

AquariusPanta

Well-Known Member

My brain is going to explodeO.M.G.

stardustsailor

Well-Known Member

Seoul Semiconductor ZC series CObs :

SDW87F1C (2700-3000K ) & SDW07F1C (4000-5000K )

http://www.seoulsemicon.com/en/html/product/product_view.asp?catecode=2012

http://www.seoulsemicon.com/_upload/Goods_Spec/SDWx7F1C_ZC100_Datasheet.pdf

http://www.seoulsemicon.com/_upload/Goods_Spec/SDWx7F1C_ZC100_Datasheet.pdf

From SDW87F1C ( warm white ) datasheet :

stardustsailor

Well-Known Member

BJB COB/led array holders-connectors .

A wide selection for most branded cobs :

http://www.bjb.com/index.php?productid=347520

Made of Polybutylene terephthalate (PBT).

http://en.wikipedia.org/wiki/Polybutylene_terephthalate

http://www.bjb.com/index.php?pid=376920&lid=4

smokey the cat

Well-Known Member

Love this thread, keep on sharing.

Look what cheap cobs is these days: here's a $50USD 50W cob spotlight

http://www.dx.com/p/50w-4500lm-6000k-1-led-white-light-floodlight-grey-black-90-240v-343710#.VEY9rtaEyYU

Fanless. Actually a really nice compact form factor. Universal voltage.

And it's a looker

Cheaper and brighter cause this really is the age of cheap led lighting we've been hearing about for decades.

Not as interesting as new cobs, sorry. Carry on.

Look what cheap cobs is these days: here's a $50USD 50W cob spotlight

http://www.dx.com/p/50w-4500lm-6000k-1-led-white-light-floodlight-grey-black-90-240v-343710#.VEY9rtaEyYU

Fanless. Actually a really nice compact form factor. Universal voltage.

And it's a looker

Cheaper and brighter cause this really is the age of cheap led lighting we've been hearing about for decades.

Not as interesting as new cobs, sorry. Carry on.

stardustsailor

Well-Known Member

stardustsailor

Well-Known Member

Modes of Driving a L.E.D. array / Chip -On-Board L.E.D. module

There are three modes of driving a L.E.D. array / Chip -On-Board L.E.D. module .

HE ,NM & HO ...

-HE stands for " High Efficiency " mode .Driving up to 50% of maximum power dissipation.

For example,driving a CREE CXA3070 up to 1400 mA .

High Efficiency,but low output mode.

-NM stands for " Nominal " mode .Driving from 50% up to 75% of maximum power dissipation.

For example,driving a CREE CXA3070 ,from 1400 mA up to 2100 mA .

Balanced efficiency versus output mode.

-HO stands for " High Output " mode .Driving from 75% up to 100% of maximum power dissipation.

For example,driving a CREE CXA3070 ,from 2100 mA up to 2800 mA .

High output,but low efficiency mode.

-----------------------------------------------------------------------------------------------------------------------

From Tridonic :

http://www.tridonic.com/com/en/products/talexxmodule-stark-fle.asp#tab4

1750 mA ( 50% of 3500 mA ) is HE mode .

2600 mA (~75% of 3500 mA ) is NM mode .

3500 mA (100% ) is HO mode .

There are three modes of driving a L.E.D. array / Chip -On-Board L.E.D. module .

HE ,NM & HO ...

-HE stands for " High Efficiency " mode .Driving up to 50% of maximum power dissipation.

For example,driving a CREE CXA3070 up to 1400 mA .

High Efficiency,but low output mode.

-NM stands for " Nominal " mode .Driving from 50% up to 75% of maximum power dissipation.

For example,driving a CREE CXA3070 ,from 1400 mA up to 2100 mA .

Balanced efficiency versus output mode.

-HO stands for " High Output " mode .Driving from 75% up to 100% of maximum power dissipation.

For example,driving a CREE CXA3070 ,from 2100 mA up to 2800 mA .

High output,but low efficiency mode.

-----------------------------------------------------------------------------------------------------------------------

From Tridonic :

http://www.tridonic.com/com/en/products/talexxmodule-stark-fle.asp#tab4

1750 mA ( 50% of 3500 mA ) is HE mode .

2600 mA (~75% of 3500 mA ) is NM mode .

3500 mA (100% ) is HO mode .

stardustsailor

Well-Known Member

Tridonic : A COB for every occasion ...

Inspired by light

Just think of a sunset at the beach, a romantic campfire or the dazzling skyline of a city at midnight ... light is naturally able to create experiences that inspire people. We offer you various component solutions to build exactly the setting you need: Luminous colours and colour temperatures to let products and employees shine. Enter the world of “Emotional Lighting” with Tridonic – for retail and office applications.

http://www.tridonic.com/com/en/news-inspired-by-light.asp

For fashion shows and clothing boutiques ...

For bakery goods and fresh or cooked meat !!!

For art and culture ...

From 2700K to 6500 !!! ( Red + NW + (? blue / cyan ? ) led array module )

http://www.tridonic.com/com/en/download/technical/TALEXXengine_STARK_SLE_PREMIUM_guide_en.pdf

.....

But then ,what about a cob for plants ?

......

Well ..

It really seems that plants not just ' settle ' (light adaption ) with every each different COB / array ...

In fact they "love" the majority of them ...

They trully flourish ,no matter which the cob is ...

https://www.rollitup.org/t/another-cree-cxa3070-diy-thread.824364/page-20#post-10987606

Still attending black plants in a violet-pink universe ?

.......

Inspired by light

Just think of a sunset at the beach, a romantic campfire or the dazzling skyline of a city at midnight ... light is naturally able to create experiences that inspire people. We offer you various component solutions to build exactly the setting you need: Luminous colours and colour temperatures to let products and employees shine. Enter the world of “Emotional Lighting” with Tridonic – for retail and office applications.

http://www.tridonic.com/com/en/news-inspired-by-light.asp

For fashion shows and clothing boutiques ...

For bakery goods and fresh or cooked meat !!!

For art and culture ...

From 2700K to 6500 !!! ( Red + NW + (? blue / cyan ? ) led array module )

http://www.tridonic.com/com/en/download/technical/TALEXXengine_STARK_SLE_PREMIUM_guide_en.pdf

.....

But then ,what about a cob for plants ?

......

Well ..

It really seems that plants not just ' settle ' (light adaption ) with every each different COB / array ...

In fact they "love" the majority of them ...

They trully flourish ,no matter which the cob is ...

https://www.rollitup.org/t/another-cree-cxa3070-diy-thread.824364/page-20#post-10987606

Still attending black plants in a violet-pink universe ?

.......

Last edited:

medicinehuman

Well-Known Member

There is never enough on COB' shttp://www.lednews.org/what-cob-led-chip-on-board-definition/

medicinehuman

Well-Known Member

stardustsailor

Well-Known Member

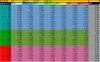

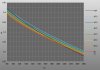

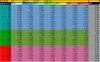

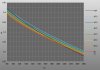

Cree CXA3070-0000-000N00AB30 H/F :

Radiometric efficiency vs Case Temperature (30°-60°C ) vs Forward Current (400-2800mA ) chart & graph.

Luminous Efficiency of Radiation ( 3000°K -CRI 80 ) : 325 Lumen / Watt

( HSF : Estimation with highly efficient Heat sink-Fan cooling. Ta=25 °C.)

Mode HE 400-1400 mA : Radiometric efficiency range tops at 52,2% (Tc=30 @400mA ),

& drops at 38.8 % (Tc=60 @1400mA ).

Mode NM 1400-2100mA : Radiometric efficiency range tops at 41.3 % (Tc=30 @1400mA ) ,

& drops at 33.3 % (Tc=60 @2100mA ).

Mode HO 2100-2800mA : Radiometric efficiency range tops at 35.6 % (Tc=30 @2100mA ) ,

& drops at 28.4 % (Tc=60 @2800mA ).

In real life applications ....

With a highly efficient HSF cooling system ,ambient temperature =25C :

HE mode starts at ~400mA and has a whopping 52,2% rad.efficiency .(Tc=30C )

HE mode shall have around 40% radiometric efficiency at 1400mA .(Tc=45C)

NM mode shall have around 34% radiometric efficiency at 2100mA .(Tc=55C)

HO mode shall have around 28% radiometric efficiency at 2800mA .(Tc=70C )

Radiometric efficiency vs Case Temperature (30°-60°C ) vs Forward Current (400-2800mA ) chart & graph.

Luminous Efficiency of Radiation ( 3000°K -CRI 80 ) : 325 Lumen / Watt

( HSF : Estimation with highly efficient Heat sink-Fan cooling. Ta=25 °C.)

Mode HE 400-1400 mA : Radiometric efficiency range tops at 52,2% (Tc=30 @400mA ),

& drops at 38.8 % (Tc=60 @1400mA ).

Mode NM 1400-2100mA : Radiometric efficiency range tops at 41.3 % (Tc=30 @1400mA ) ,

& drops at 33.3 % (Tc=60 @2100mA ).

Mode HO 2100-2800mA : Radiometric efficiency range tops at 35.6 % (Tc=30 @2100mA ) ,

& drops at 28.4 % (Tc=60 @2800mA ).

In real life applications ....

With a highly efficient HSF cooling system ,ambient temperature =25C :

HE mode starts at ~400mA and has a whopping 52,2% rad.efficiency .(Tc=30C )

HE mode shall have around 40% radiometric efficiency at 1400mA .(Tc=45C)

NM mode shall have around 34% radiometric efficiency at 2100mA .(Tc=55C)

HO mode shall have around 28% radiometric efficiency at 2800mA .(Tc=70C )

D.I.Y. Note :

It will be wise enough never to run any type of COB at HO mode .

(75%-100 % of max power dissipation) .

Yeap,better to forget about any kind of "HO operational mode".

It's counter -productive ,energy-consuming,the COBs shift to cooler CCT ,their service life decreases,cooling needs in power terms are 'way out of line' and many more bad-bad things are waiting ,hidden behind the "HO operating mode" .

The rest :

*High Efficiency Mode -(up to 50% of COB's max power.)

One efficient way of course ,is to run HE mode ,and 'make up ' for the low output ,

by using more units of COBs.Cooling is also somewhat easier as an aspect,as of dealing with lower heat power per COB unit.Light spreading & power distribution also ,are close to optimum.The drivers may be dimmable ,offering greater versatility / power savings in case of seedlings/clones/SOG/SCROG/"MILK s".(Mothers I'd Like to Keep .)

* "Pure HE" -

As before ,but the drivers are not dimmable,having a preset output current.

Thus they operate at high efficiency.Most efficient way .

* High Efficiency Mode & Nominal Mode -(up to 75% of COB's max power)

Another way will be using less units of COBs but more powerful drivers ,running the COBs

at NM mode ...Not as efficient way ,but allows for smaller light fixtures.Thus ,a more preferable way for tighter budgets and /or tighter available spaces.Cooling becomes a serious issue,in such case.Use of optics (reflectors mainly),may prove a real enhancement / aid ,also.

* "Multi HE&NM " .(HE & NM modes / multiple units )

Use of multiple COB units / fixtures ,driven with dimmable high power drivers.

Plenty of units & plenty of available power.

The most 'versatile' & 'powerful' ,but also most expensive way .

(Still not as efficient as a "pure HE". Total efficiency is COB eff. multiplied by PSU eff.

Dimmable drivers have their highest efficiency when operated to their full load or close.

So ,at low currents of HE operating mode ,a dimmable high power driver will 'under-perform' counter-acting the high efficiency of COBs ,thus the total efficiency will be decreased,compared to a pure HE mode system using non-dimmable drivers .)

Last edited:

Dloomis514

Well-Known Member

Gonna get me some!

FranJan

Well-Known Member

Philips Luxeon COBs

http://www.philipslumileds.com/

LUXEON COB Application Brief:

http://www.philipslumileds.com/uploads/426/AB115-pdf

LUXEON COB Product Datasheet:

http://www.philipslumileds.com/uploads/419/DS115-pdf

Luxeon with Crisp White

LUXEON CoB with CrispWhite Technology Product Brief:

http://www.philipslumileds.com/uploads/483/PB138-pdf

LUXEON CoB with CrispWhite Technology Datasheet:

http://www.philipslumileds.com/uploads/482/DS138-pdf

Features & Benefits

- 90CRI with CrispWhite enhancement for perfect combination of warm colors and white that stands out!

- Hot targeted within a 3-Step MacAdam Ellipse below the BBL that is ideal for CDM-CMH replacement

- Creating a second blue peak (~410-415nm) in the spectrum that activates fluorescent whitening agents paints/fabrics

- Lumen packages from 1,000 to >5,000 lumens and efficacies of >90 lm/W

- Real world application testing conditions at Tj=85°C

- Robust MCPCB solution - easy to handle in manufacturing and operations

- Mousebites for M2/M3 easy to screw down arrays

Attachments

-

49.4 KB Views: 12

-

166.5 KB Views: 3