To reflow solder successfully ceramic leds into mcpcb stars ,is not such difficult job ...

Her's some advices :

-

Solder that MUST be used has to fall within the JEDEC J-STD-020C standards.

That being usually solder alloys containg Ag (silver ) .

Due to silvers extreme thermal durability ,oxidation resistance,low gas absorbtion during liquidus phase and some more ..

The usuall solder alloy used for the best and quality reflow is

SnAg3Cu.5 .

tin/bismuth solder ,like the Sn42/Bi58 ,tend to absorb gasses from atmospheric air ,thus final solder point has bad thermal conductance characteristics and

heat from leds will 'ages the solder prematurely ...

Also this alloy is brittle enough ,to point that a solder point can fail under different thermal expansion coeffs of

Solder alloy ,ceramic of led (AlO or AlN )and pcb copper pad ...

This solder type,ain't for high power leds ...

(...)Alloy for low temperature applications. Attention should be

paid to potential embrittlement issues and poor thermal

fatigue properties. (...)

http://www.aimsolder.com/sites/default/files/lead-free_alloy_information.pdf

-Get a multimeter with a

K-type thermocouple thermometer feature (cheap ones $5-10 are more than fine )

Attach the tip of the thermocouple to the kitchen stove plate (use plenty of capton tape ) ..

Not on the mcpcb star ! ( .............................^^^^^ ^^^this way you play safe !! )

Get a timer / clock ....

At same time pay attention to multimeters display ,the time and the solder profile ....

Your hand at the stoves heat adjustment knob (usually marked 1 to 9 )

Try to follow the solder reflow profile .

Keep the temperature ramps ,in relation with time ,as close to the solder profile.

Manually ,I trust that one enough experienced ,can achieve really amazing results !!

Use some old stars / fried leds .Not the new ones !!!

After the third-fourth time ,you will realise that is actually a piece of cake ...

Reflow solder and unsolder (use tweezers to handle the leds &

make a habit to 'ground '/'earth' yourself with the special wristwrap ),some times more ,

to "master" the procedure ..

Roughly ...For SnAg3.5Cu ,on an 'ordinary' stove plate (medium size ) ..

1) For the first ~30-60 sec ,heat set at " 4 " ( rise from ambient to ~150 C )

2) The next 120 sec ,heat 'plays ' between 3-5 ....Slowly rising to 180-200 C )

3) the next 30 sec heat goes to 6-7-8-9-8-7-6 ..Heat now is about 220,rising to ~ 230-240 C ...

4) Turn off ,totally the heat ....Blow slowly / softly the star with your mouth/fan ..

Move it away from stove plate ,but only when the solder has solidify ....

Keep it near ,at the borders of the stove plate ,so to cool slowly ...

After ~30-40 sec ,remove it and let cool down ....

That was it ...

More or less ...

Practicing on it ,will most probably be very ..'enlightening ' ....

-The "Weak" point of the whole procedure is the cooling state ....

if cooling is done fast ,led die might chip off ,or led case might crack ..

Ceramic leds do tolerate lots of heat abuse ...meaning high temperatures-

nothing there to melt ..Ceramics-metals-semiconductors-silicone ..none of these materials used,melts or deforms under 500-600C...

But not sudden changes of temperature .They can chip or crack ...

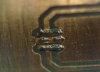

-use a ( led ) pad stencil to apply the solder paste in a really thin layer ( 2/10 of one millimeter = 200 micro thickness of solder paste ).

A good

solder stencil is the 90% of a successful reflow solder !

Use your imagination ,how to make one ....

That's the most difficult part of all !!!

Making a good pad stencil .

Good luck with that one !

Reflow is actually very easy (regarding a single star mcpcb )...

Needs a bit of practice ...

Oh ..

Almost forgot !

Space Monkey Rules !

They say that I'm a clown

Making too much dirty sound

They say there is no place for little monkey in this town

Nobody'd like to be in my place instead of me

Cause nobody go crazy when I'm bangin' on my boogie

I'm the (king of the bongo, king of the bongo bong)

Hear me when I come, baby

(King of the bongo, king of the bongo bong)

Hear me when I come

[video=youtube;vJMLJVha5sw]http://www.youtube.com/watch?v=vJMLJVha5sw[/video]