pulpoinspace

Well-Known Member

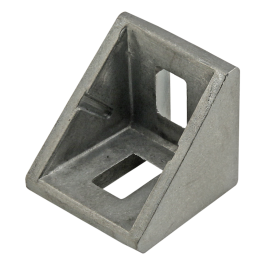

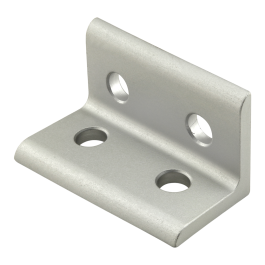

End pieces making any frame build "easier" or "better" I get. But I don't get the truss head screws suggestion, when I might as well just use tnuts...not sure specifically why you're suggesting these screws. Also, are you saying screw a tnut (or truss screw, whatever the case) directly to the heatsink? Won't work; can't tighten in place, and see dimensions of heatsink.

You can use t-nuts if you want. Yes directly into the heat sink. What do you mean it can't tighten in place? m4x10 fits directly into the holes on the side of the heatsink. m4x12 sticks out a little. m4x15 sticks out a half a centimeter.

Do you mean that once you have it slid to the spot where you want it you'd also like some mechanism to lock it there?

I can guarantee it works as this is how my SSTX heatsinks have been sliding in and out of my frame for years now!

I suggested trusshead screws cause you can get a pack of M4x15 truss head screws for the same cost as 1 specially made t-nut.