You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

120x120cm tent with LEDs

- Thread starter KonopCh

- Start date

ThaMagnificent

Well-Known Member

Best bang for the buck is the ApolloWhat tent did you go with, I am in the market for a 4x4.

skoomd

Well-Known Member

Best bang for the buck is the Apollo

I muuuuuuch prefer vivosun for the price, their tents are much thicker and high quality IME.

To op: Id add in 4x 1120mm double row strips driven at 100w each around the sides, aka 50% of their max current. That's including your COB fixture. I think that would work great, and give you about 600w of power in the space. They're not quite as long as your tent, so you'll be able to squeze them in. Let me know if this is what you're thinking. You could use an HLG -480H-48 driver to power them.

Randomblame

Well-Known Member

If you do not want to take the old ones apart, we have a problem.

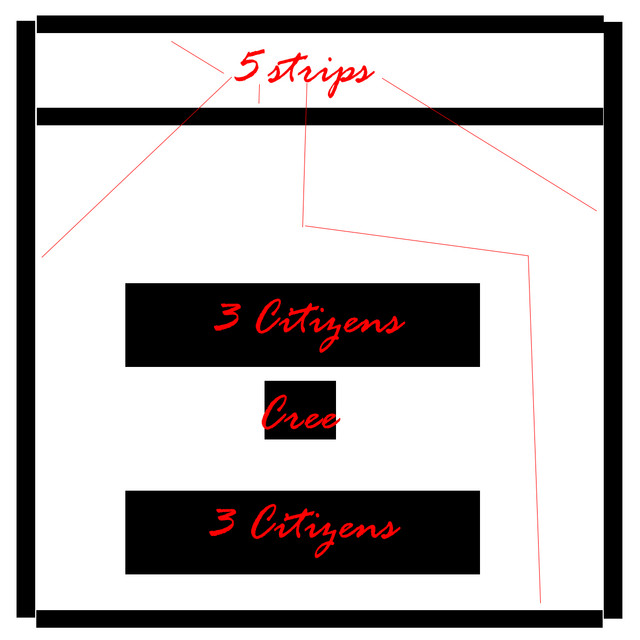

But you could still buy 1 Cree CXB and 2 Citizens or 3 CXB's to have 10 COB's. Then you could hang 2 parallel strings to a HLG-240H-C1400B so that each string gets 700mA or you take a HLG-185H-C1050B and run it with 525mA.

Re-arrangement for a homogeneous coverage could look like shown below.

However, you would need two more heatsinks for the 3 additional COB's. With 525mA you could drive the COB's passively and mount them to selfmade heatsinks. The two below are made from two different c-channels, one is 1" wide the big one is 2" wide. Glue the small one into the big one using the same thermal tape as you use to mount the strips on, it's sticky like hell and works well.(no temp differences)

At 525mA(~17w) the COB's would be almost 60% efficient, that means, they only produce ~6.8w heat (~10.2PAR/w). 6,8w x 110cm²(cooling surface for 1w heat) = 748cm², so you need a 25-30cm piece of such a DIY heatsink per COB, 50-60cm for two COB's.

So you would need three more COB's and two 4ft. c-channels(1" and 2" wide) to make the two 2ft heatsinks.

Everything 100% DIY and done quickly!

KonopCh

Well-Known Member

How apart, what you mean? Did you read my older posts in previous page? Now I have 2 different setups, it's clearly you didn't read my posts.

I like your idea on previous page, but only problem is ... well, that you didn't read what light I have now and how big/small it is for new tent. Maybe mount it in a line, so I get 1m heatsink and 6 COBs on it? So like one big fat strip.

What's difference between single and double row strips, beside twice the diodes, flux and volts/watts? What's better? What's efficiency?

I like your idea on previous page, but only problem is ... well, that you didn't read what light I have now and how big/small it is for new tent. Maybe mount it in a line, so I get 1m heatsink and 6 COBs on it? So like one big fat strip.

What's difference between single and double row strips, beside twice the diodes, flux and volts/watts? What's better? What's efficiency?

Last edited:

Randomblame

Well-Known Member

How apart, what you mean? Did you read my older posts in previous page? Now I have 2 different setups, it's clearly you didn't read my posts.

I like your idea on previous page, but only problem is ... well, that you didn't read what light I have now and how big/small it is for new tent. Maybe mount it in a line, so I get 1m heatsink and 6 COBs on it? So like one big fat strip.

What's difference between single and double row strips, beside twice the diodes, flux and volts/watts? What's better? What's efficiency?

I mean, you had to disassemble and rearrange them. (language barrier, sorry)

The goal is to achieve as homogeneous coverage as possible and you can only do that if you rearrange everything.

More work, but worth it!

You could even take a 1150x 1150mm aluminum plate (at least 5-6mm thick) and just stick all the COB's and strips on it. It would be enough to dissipate 240w of pure heat(600w of 60% efficient LED), passively with absolute no airflow.

Like the HLG550 only a tad bigger.

Glue further C-channels to the backside to stiffen the plate and further increase the cooling capacity.

Less work but more expensive.

BTW, I read every single post when I follow a thread, which is not even difficult with only 2 pages, lol!

KonopCh

Well-Known Member

Thanks for input @Randomblame.

But even if I de-mount curent light, it's still not like your painting, if I want reuse those big ass heatsinks. Each was 40€ I think, so 80€ for heatsinks. I think I will put this light in one corner at 700mA like you said (with CREE in the middle), and the other corner will be 560mm strips. Then other two corners (half tent) will be 1120mm strips. Should be nice coverage. Just need to find proper drivers now. Can I wire 560mm and 1120mm strips on the same driver? How much base thicknes of ALU I need? Just plate, not heatsink fins at the back.

Hmm... I like idea about 1150x1150 ALU plate!! I will call around if I can get one. If not, then above option I think will be the choice.

How far apart should be strips? 10cm from center to center of strip?

Can anyone answer my question about difference (look previous post)?

But even if I de-mount curent light, it's still not like your painting, if I want reuse those big ass heatsinks. Each was 40€ I think, so 80€ for heatsinks. I think I will put this light in one corner at 700mA like you said (with CREE in the middle), and the other corner will be 560mm strips. Then other two corners (half tent) will be 1120mm strips. Should be nice coverage. Just need to find proper drivers now. Can I wire 560mm and 1120mm strips on the same driver? How much base thicknes of ALU I need? Just plate, not heatsink fins at the back.

Hmm... I like idea about 1150x1150 ALU plate!! I will call around if I can get one. If not, then above option I think will be the choice.

How far apart should be strips? 10cm from center to center of strip?

Can anyone answer my question about difference (look previous post)?

Randomblame

Well-Known Member

1. Nope, the 2 footers would need their own driver

2. 2mm for C-channels is okay

3. 10cm is okay

For cheap aluminum call the next scrapyard or look at e3ay. Found some good stuff at the scrapyard at a kilo price base.

2. 2mm for C-channels is okay

3. 10cm is okay

For cheap aluminum call the next scrapyard or look at e3ay. Found some good stuff at the scrapyard at a kilo price base.

KonopCh

Well-Known Member

1. Nope, the 2 footers would need their own driver

2. 2mm for C-channels is okay

3. 10cm is okay

For cheap aluminum call the next scrapyard or look at e3ay. Found some good stuff at the scrapyard at a kilo price base.

Yep, that I was thinking. We have some companies here which handles ALU.

Really thank you for your time, knowledge and answers!!

KonopCh

Well-Known Member

What's better choice for 4x4 tent, Samsung or Bridgelux? Can someone give me LPW numbers for 1050mA and 1280mA (max current for my driver)? For both BLux and Samsung please.

I plan to use 1120mm strips, I already have one HLG-240H-C1050A driver (238V max.), so 5 Samsung strips fits perfectly, or 6 Bridgelux maybe? Vf of Bridgelux at 700mA is 39V, how much is at 1050mA or 1280mA?

I plan to use 1120mm strips, I already have one HLG-240H-C1050A driver (238V max.), so 5 Samsung strips fits perfectly, or 6 Bridgelux maybe? Vf of Bridgelux at 700mA is 39V, how much is at 1050mA or 1280mA?

nfhiggs

Well-Known Member

Your looking at a 1-2 v higher Vf for those currents - but cold Vf can be as high as 44.1V at 1400 mA - 42.1 V at 700 mA. I'd go with 5 strips or the driver may not start.Vf of Bridgelux at 700mA is 39V, how much is at 1050mA or 1280mA?

You'll find this in the spec sheet under driver selection voltages in the electrical characteristic section..

KonopCh

Well-Known Member

Your looking at a 1-2 v higher Vf for those currents - but cold Vf can be as high as 44.1V at 1400 mA - 42.1 V at 700 mA. I'd go with 5 strips or the driver may not start.

You'll find this in the spec sheet under driver selection voltages in the electrical characteristic section..

Thank you! I've read my driver is not recommended because of high voltage, but can anything go wrong if I ground like I should? What do you recommend for other 5 strips? Or better say, for other 250W.

Can someone give me answers to first question? I don't know how to use calculator.

nfhiggs

Well-Known Member

I just use CV supplies and run parallel setups. Simpler that way and you can build in surplus power from the start for easy expansion later on.Thank you! I've read my driver is not recommended because of high voltage, but can anything go wrong if I ground like I should? What do you recommend for other 5 strips? Or better say, for other 250W.

Can someone give me answers to first question? I don't know how to use calculator.

KonopCh

Well-Known Member

@Randomblame okay, now I know what can I get.

30 x 30 x 2 mm U channels or 40 x 25 x 3 mm U channels? I want to drive them at 1.05A, not sure yet if Samsung or Bridgelux single row.

Ambient temp is usually 25-30°C, I want maximum passive cooling in tent.

30 x 30 x 2 mm U channels or 40 x 25 x 3 mm U channels? I want to drive them at 1.05A, not sure yet if Samsung or Bridgelux single row.

Ambient temp is usually 25-30°C, I want maximum passive cooling in tent.

Randomblame

Well-Known Member

I've used 25x 25x 2mm "U-profiles" (that's the term I've used for e3ay searches in GER), and the highest temp reading was ~35°C with 29°C ambient but I run mine(2ft. single row's) only with 525mA(~12w).

I would use the 30x 30x 2mm for single row and the 25x 40x 2mm with double row strips. 3mm thickness is just overkill and simply don't needed. I'm pretty sure one can also use 1mm even if they have less stability. They'll be fixed to a frame anyway, so they'll stay stable enough and the surface(cooling) area would also be the same.

Not to mention the cost savings. After all, they only weigh half as much.

I recommend you to look at e3ay, there they are much cheaper than for example. at "Bleche.de", which is one of the cheapest online alu providers with us.

At e3ay I found them at half price.

I would use the 30x 30x 2mm for single row and the 25x 40x 2mm with double row strips. 3mm thickness is just overkill and simply don't needed. I'm pretty sure one can also use 1mm even if they have less stability. They'll be fixed to a frame anyway, so they'll stay stable enough and the surface(cooling) area would also be the same.

Not to mention the cost savings. After all, they only weigh half as much.

I recommend you to look at e3ay, there they are much cheaper than for example. at "Bleche.de", which is one of the cheapest online alu providers with us.

At e3ay I found them at half price.

Last edited:

Randomblame

Well-Known Member

I've used 25x 25x 2mm "U-profiles" (that's the term I've used for e3ay searches in GER), and the highest temp reading was ~35°C with 29°C ambient but I run mine(2ft. single row's) only with 525mA(~12w).

I would use the 30x 30x 2mm for single row and the 25x 40x 2mm with double row strips. 3mm thickness is just overkill and simply don't needed. I'm pretty sure one can also use 1mm even if they have less stability. They'll be fixed to a frame anyway, so they'll stay stable enough and the surface(cooling) area would also be the same.

Not to mention the cost savings. After all, they only weigh half as much.

I recommend you to look at e3ay, there they are much cheaper than for example. at "Bleche.de", which is one of the cheapest online alu providers with us.

At e3ay I found them at half price.

BTW, for 250w I would recommend to use a HLG-240H-24A for parallel wiring, a HLG-240H-48A for series/parallel wiring(each two strips wired in series and all pairs wired in parallel) or an HLG-240H-C1050 or 1400B to run all the strips in series.

For the sake of simplicity, I would recommend the first one which is a CV driver. You can easily wire several stripes in parallel with the help of Wago's and you can add more stripes later to make the lamp more efficient if you want. With series wiring the number of strips needs to match with the min./max. voltage requirements of the driver. The HLG-240H-C1050B provides for instance 118-238v, that is at least 5 to max. ten 23v F-strips in series.

With parallel wiring the number of strips doesn't matter. For wiring examples check LEDgardeners website, he has made lot's of well illustrated examples.

KonopCh

Well-Known Member

Thank you, so I will go with 30x30x2mm profiles. I will go with single row strips, because that way I can get better coverage.

I already have one 240H-C1050A, so this will be for 5 strips. Perfect, 230V used from 238V available.

The second one I can get... I don't know, maybe the same driver. I will not adding strips later, so this is no point/plus for me. I am building light that will last me 3-4 years. Later on it will be too old, efficiency and love for making lights will go to the roof!

Thank you again, see you soon when I get strips!

I already have one 240H-C1050A, so this will be for 5 strips. Perfect, 230V used from 238V available.

The second one I can get... I don't know, maybe the same driver. I will not adding strips later, so this is no point/plus for me. I am building light that will last me 3-4 years. Later on it will be too old, efficiency and love for making lights will go to the roof!

Thank you again, see you soon when I get strips!

KonopCh

Well-Known Member

@Randomblame I found cheap ALU on ebay, like you said. Price for 30x30x2 is the same as 70x30x3. It's maybe better if I oversize heatsinks? Will be ALU/strips/Tc cooler then?

Randomblame

Well-Known Member

I'm using 1150mm c-channels, 25x 25x 2mm, each has two 2footers in series running around 400mA currently(dimmed to 80%, ~18w net.) and my temp readings @30°C ambient yesterday are 35°C on the backside(cover the metal surface with a piece of black tape if you use an IR-thermometer) and ~33° on the center measuring point on the strips front side.

Testings done with 1050mA/~48w/30°C ambient shifted the readings to about 45°C on the back and around 50°C frontwise. Still cool to touch.

Both tests were done under mostly real conditions. That means, in a closed chamber with a circulating/oszillating fan blowing horizontally underneath the fixture and an extractor fan at the lowest settings.

So they get only some fairly low airflow.

This is a temperature test done by another rui member with EBgen.1 strips, should give you a better idea about the expected temps.

Testings done with 1050mA/~48w/30°C ambient shifted the readings to about 45°C on the back and around 50°C frontwise. Still cool to touch.

Both tests were done under mostly real conditions. That means, in a closed chamber with a circulating/oszillating fan blowing horizontally underneath the fixture and an extractor fan at the lowest settings.

So they get only some fairly low airflow.

This is a temperature test done by another rui member with EBgen.1 strips, should give you a better idea about the expected temps.

KonopCh

Well-Known Member

Okay, thank you @Randomblame !

Just to be sure I am asking again - how far away can be centers of the strips? Single row strips.

Hmm... still didn't decided which strips I should use. Digikey don't have 1120mm strips in stock in 3000K or 3500K color, no Samsung, no Bridgelux. Any other EU company that offers single row strips?

Otherwise I should order from Digikey 10x 560mm single row Samsung in 3500K.

Just to be sure I am asking again - how far away can be centers of the strips? Single row strips.

Hmm... still didn't decided which strips I should use. Digikey don't have 1120mm strips in stock in 3000K or 3500K color, no Samsung, no Bridgelux. Any other EU company that offers single row strips?

Otherwise I should order from Digikey 10x 560mm single row Samsung in 3500K.