Thoughts on this LED

- Thread starter luvhandles

- Start date

r8rfanizme

Member

those lights are built with Cree LED chips. They are what the do it yourself crowd are using on this forum. If you have building skills, you can make something yourself for about half the cost.

Hydroburn

Well-Known Member

I replaced a 400w MH with a 190w area 51 that uses white crees. I have not completed a flower run with it, but in veg it was much better growth. Also much cooler and quieter since I did not have to run an inline fan... I struggled with temps in my closet with HID. I have it flowering now, would like to replace the veg area with LED too.

luvhandles

Member

sounds like a good investment plus it is compact for small units and angles too but the do it yourself will take time and practice. I learned that now the different spectrums work with different strains to suffice its genetics like bringing out the fruity quality in fruity juice etc.Looking to produce quality for patients an the LED seems like a good start? Since no access to clones, I think this brand LED will suffice seed germination while increasing the maximum quality in one strains potential potency though I am learning please bare with me maybe wrong anyways?

luvhandles

Member

Is that what you prefer area51 sunny747post this in the LED section to make sure the LED growers see it.

That looks like a good light. It's so difficult to say though. What watt cree's are they using? Area51 seems to be trusted and on the cutting edge. I'd have no problem buying from Area51.

sunny747

Well-Known Member

I think the area of LED is amazing and it's advancing very rapidly. By the time your lamp arrives there will be a new version. That's just the nature of it. I know that the developer of Area 51 really takes growing MJ seriously and his lights are well priced. Every person I have spoken to that has an Area 51 believes that they purchased a quality product. There are so many rip off companies out there.Is that what you prefer area51 sunny747

The new Area 51 RW150 looks great to me.

The light you posted the video of looks great also, but without more info it'd be hard to dish out $1000.

luvhandles

Member

Oh yeah, I like how you think it is a lot of money this is why I wanted to hear experience on this plus LEDs do well with FLIR Cameras by the PD and DEA not that I would indulge in such acts : )I think the area of LED is amazing and it's advancing very rapidly. By the time your lamp arrives there will be a new version. That's just the nature of it. I know that the developer of Area 51 really takes growing MJ seriously and his lights are well priced. Every person I have spoken to that has an Area 51 believes that they purchased a quality product. There are so many rip off companies out there.

The new Area 51 RW150 looks great to me.

The light you posted the video of looks great also, but without more info it'd be hard to dish out $1000.

sunny747

Well-Known Member

Aww mann.. If I wasn't in a legal state I think there is no way I would grow. It's enough worry just stressing over plant problems, getting discovered by the landlord and fire risks much less losing my house and ending up with a bunch of legal fees..

For some reason our government spends tens of millions of dollars for brainwashed nazis to zzom around in state of the art military vehicles looking for hot spots in people's roofs, yet tonight I must have seen 6 people racing, 5 people on their phone, one guy watching a movie while driving and ten obviously drunk people driving around. Strange..

For some reason our government spends tens of millions of dollars for brainwashed nazis to zzom around in state of the art military vehicles looking for hot spots in people's roofs, yet tonight I must have seen 6 people racing, 5 people on their phone, one guy watching a movie while driving and ten obviously drunk people driving around. Strange..

luvhandles

Member

Days are getting stranger by the moment sunny747. I observed 15 police officers fully vested lined up along the interstate with firearms AR-15s yet to know why? Welcome the brave new world time for the total control by the select elite not far from sight. Like the government that lost 5 billion dollars in defense budget and supposedly don't know where it went?Aww mann.. If I wasn't in a legal state I think there is no way I would grow. It's enough worry just stressing over plant problems, getting discovered by the landlord and fire risks much less losing my house and ending up with a bunch of legal fees..

For some reason our government spends tens of millions of dollars for brainwashed nazis to zzom around in state of the art military vehicles looking for hot spots in people's roofs, yet tonight I must have seen 6 people racing, 5 people on their phone, one guy watching a movie while driving and ten obviously drunk people driving around. Strange..

They don't show the LEDs inside the lamp. But, it doesn't seem to be COB. I found the following on the SpectrumKingLED website. Would be interesting to hear what the DIYers here think about this:those lights are built with Cree LED chips. They are what the do it yourself crowd are using on this forum. If you have building skills, you can make something yourself for about half the cost.

==== >>>

C.O.B Myth and High Wattage LEDs

Another point of confusion for customers is the constant advertisement of a new unheard of C.O.B. (Chip On Board ) LEDs and how they will dominate the market. As a Commercial lighting manufacturer we are here to tell you that is 100% FALSE!!

C.O.B. LEDs have been around for over 10 years. There are only three reasons to choose a C.O.B. LED:

- To reduce cost of materials to make the LED

- To save companies money by eliminating the need for circuit boards

- To group more LED diodes into one small area.

DO NOT BE FOOLED BY COMPANIES THAT CLAIM TO OFFER HIGH WATTAGE CHIPS!!!

Additional downsides to C.O.B. is the relatively lower efficiency and overall light output. By adding and cramming more diodes into a tight array that share the same substrate; heat becomes an issue and C.O.B. diodes run hotter and thus output less lumens, have a lower efficiency, and shorter life. 100 Watts of C.O.B. does not equal to or perform the same as a cluster of individual diodes mounted on a circuit board. Not opinion, fact.

<<<=======

churchhaze

Well-Known Member

Wow... So... cobs are cheaper to manufacture, produce, and allows you to put more diodes in a smaller area... and that's why it's a myth that COBs will soon dominate the market?

Cobs already dominate my market.

Their reasons why COBs will be a failure are exactly the reason why DIYers love COBs so much. Do you want to mount and wire a 20W cob or 4x5W leds?

COBs have enabled the lazy to get into DIY leds.

The big cobs let you dissipate up to 100W in one unit.

That company claims that individual LEDs have DOUBLE the performance of COBs. Well wtf is their definition of performance? The efficiency of top bin warm whites for individual leds and top bin cobs is about the same.

Cobs already dominate my market.

Their reasons why COBs will be a failure are exactly the reason why DIYers love COBs so much. Do you want to mount and wire a 20W cob or 4x5W leds?

COBs have enabled the lazy to get into DIY leds.

The big cobs let you dissipate up to 100W in one unit.

That company claims that individual LEDs have DOUBLE the performance of COBs. Well wtf is their definition of performance? The efficiency of top bin warm whites for individual leds and top bin cobs is about the same.

C.O.B Myth and High Wattage LEDs

Another point of confusion for customers is the constant advertisement of a new unheard of C.O.B. (Chip On Board ) LEDs and how they will dominate the market. As a Commercial lighting manufacturer we are here to tell you that is 100% FALSE!!

C.O.B. LEDs have been around for over 10 years. There are only three reasons to choose a C.O.B. LED:

Standard self contained diodes are the leading LEDs in the Industry and have performances that are double that of C.O.B. LEDs. Every LED that claims to be 10, 20, 50 or even 100 watt is a C.O.B.

- To reduce cost of materials to make the LED

- To save companies money by eliminating the need for circuit boards

- To group more LED diodes into one small area.

DO NOT BE FOOLED BY COMPANIES THAT CLAIM TO OFFER HIGH WATTAGE CHIPS!!!

Additional downsides to C.O.B. is the relatively lower efficiency and overall light output. By adding and cramming more diodes into a tight array that share the same substrate; heat becomes an issue and C.O.B. diodes run hotter and thus output less lumens, have a lower efficiency, and shorter life. 100 Watts of C.O.B. does not equal to or perform the same as a cluster of individual diodes mounted on a circuit board. Not opinion, fact.

<<<=======

Last edited:

churchhaze

Well-Known Member

This statement is laughable...

Bridgelux vero series cobs leds are on a copper substrate which is held to a heat sink with screws... Mounting to a circuit board is barbaric... We may as well use candles for light. Get real....

Bridgelux vero series cobs leds are on a copper substrate which is held to a heat sink with screws... Mounting to a circuit board is barbaric... We may as well use candles for light. Get real....

100 Watts of C.O.B. does not equal to or perform the same as a cluster of individual diodes mounted on a circuit board. Not opinion, fact.

<<<=======

churchhaze

Well-Known Member

The outside dimension of the light is 12.5x12.5". The reflector is about 8" diameter. At it's base it's about 4". His "LED 101" says COBs and high-watt LEDs are junk. Do you have any thoughts on what he could put in that 4" area to draw 440w actual? And, how that tightly packed bunch of emitters wouldn't suffer from the same deficits he accuses COBs?They're just afraid you'll figure out to do DIY... so they're trying to make you HATE cobs while you're young!!

This seems unfortunate. It looks like a very nice design, he claims to use Cree (and explains the problems with low-quality epi-whatever chips made on the mainland). But something seems "off" about the way he denigrates COBs while not showing any photos of the base of his reflector. I almost wonder if he doesn't use COBs but is claiming he doesn't. His own "secret sauce" gimmick. "That's not a COB! It's our proprietary LOB, LED on board. We can't explain how it's different because our competition would kill for that information."

He's in Canoga Park which is home to California Lightworks. That's exactly the kind of nonsense they'd pull.

nevergoodenuf

Well-Known Member

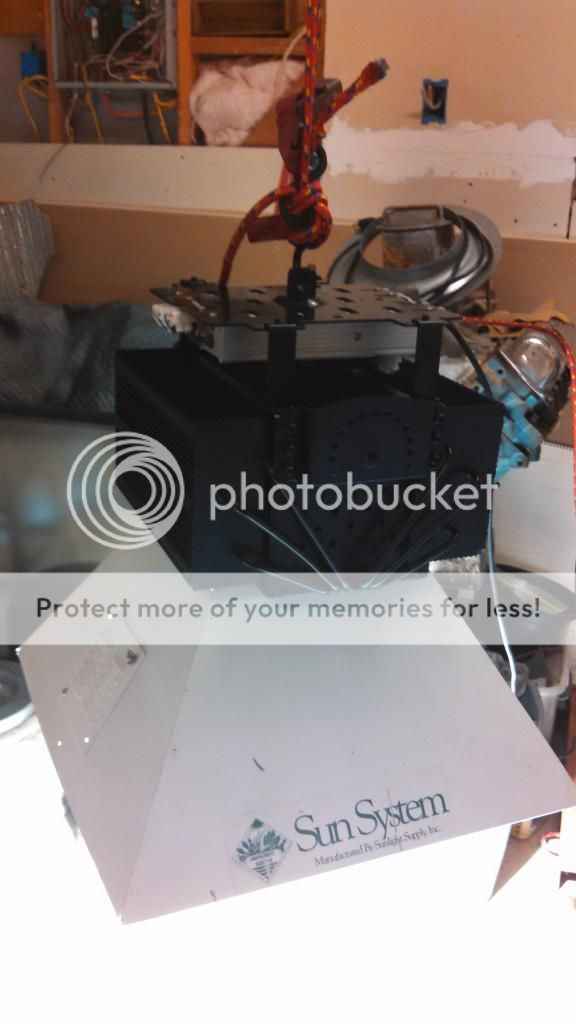

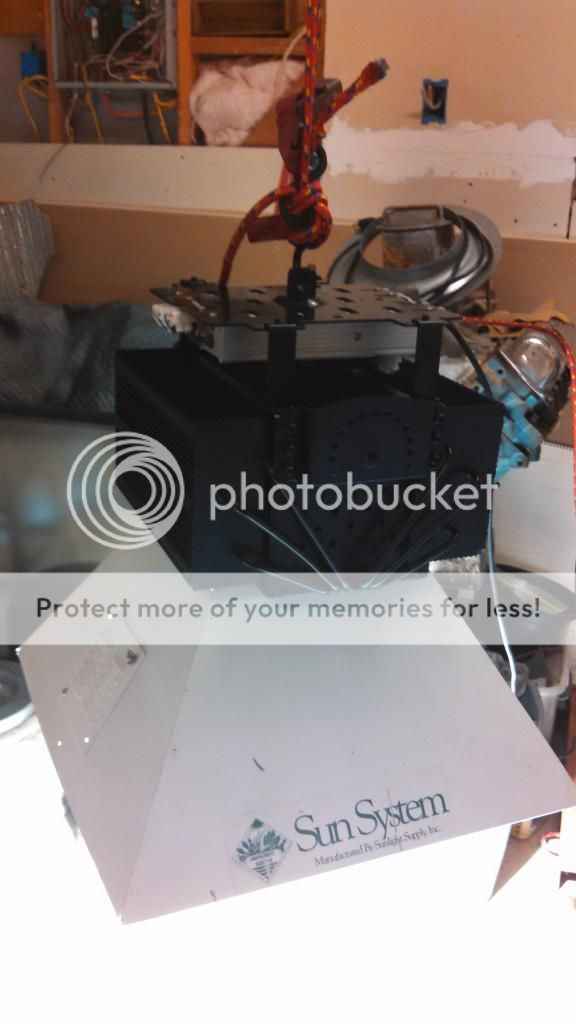

This light has many forms. It can be made with different leds, drivers and reflector angles. I have one that is 500 watts with a mixed spectrum. This was a custom set-up for me. Mine uses SMD2525 XBD series Cree leds and a meanwell dimmable driver. I went with a 60%WW, 20%NW, and 20%PW. Yesterday I was finally able to test this light with a PAR meter against a 1000 watt HPS. The HPS hit 1200umols @ 24" and the LED hit 1160 @ 24". On the lux meter the led was slightly higher (sorry, forgot the #s). The only change I made to the light was removing the round reflector and replacing it with a square HPS hood. At 12" it covers a 4'x4' area now. I have not gotten a run with out problems yet. First time running it @ over 24", it nearly kill (fried) 2 3' tall plants. Then I ended up fighting spidermites and powder mildew. I now have a dehumidifier and a mini-split with heat pump. No more issues. I will be starting 16 OG's under it shortly.

churchhaze

Well-Known Member

I mean they're worlds better than epistar, that's for sure. It's obvious they're not knockoffs because the footprint of epistar on the pcb are obvious.

It's just that you can get way better for the price. That DIY light I showed you was a 10"x10" chunk of aluminum with a 0.3" base and 1" tall fins. That's a huge heat sink for just 80W. It cost me 31 dollars!

The 4 cobs were about 14 dollars each, and the driver was about 55. That puts the project at about 150 dollars. Add in the wires, screws, hangers, connectors, etc, and you can say it's about 170 dollars to build. I made 3 of them and used them to cover a 4'x2' tent.

Because cobs allow you to pack leds so close together, you can run each led at a lower power to squeeze out efficiency without having to deal with actually wiring them. In other words, if you want to pay for efficiency, you can buy a denser cob and run it at the same power as a less dense cob. It's the same amount of work to screw in and connect. 2 screws.

Then... the real deal breaker for the old style metal pcb mounted leds is the difficulty of soldering them onto the metal pcb. Cobs have isolation between the thermal slug and the solder pads, making soldering a piece of cake. Fixing one of the leds on that giant metal pcb would be hell because the pcb would wick up the heat faster than you could source it. Good luck.... You'd need to put the whole thing into a reflow oven!

It's just that you can get way better for the price. That DIY light I showed you was a 10"x10" chunk of aluminum with a 0.3" base and 1" tall fins. That's a huge heat sink for just 80W. It cost me 31 dollars!

The 4 cobs were about 14 dollars each, and the driver was about 55. That puts the project at about 150 dollars. Add in the wires, screws, hangers, connectors, etc, and you can say it's about 170 dollars to build. I made 3 of them and used them to cover a 4'x2' tent.

Because cobs allow you to pack leds so close together, you can run each led at a lower power to squeeze out efficiency without having to deal with actually wiring them. In other words, if you want to pay for efficiency, you can buy a denser cob and run it at the same power as a less dense cob. It's the same amount of work to screw in and connect. 2 screws.

Then... the real deal breaker for the old style metal pcb mounted leds is the difficulty of soldering them onto the metal pcb. Cobs have isolation between the thermal slug and the solder pads, making soldering a piece of cake. Fixing one of the leds on that giant metal pcb would be hell because the pcb would wick up the heat faster than you could source it. Good luck.... You'd need to put the whole thing into a reflow oven!

Last edited:

churchhaze

Well-Known Member

You must be new around here... Where should I begin...

Okay, first off, the datasheet for a bridgelux vero 18 3500k 80cri states that at 85C case temperature at at test current of 1050mA , the luminous efficacy is 112lm/W and 125lm/W at 25C. The 4 vero 18 running on that large heatsink are being underdriven at 700mA, which increases luminous efficacy significantly more. 125lm/W is higher than 60-70lm/w. There is no luck here, only good engineering.

http://www.bridgelux.com/wp-content/uploads/2013/10/DS32-Bridgelux-Vero-18-Datasheet.pdf

Your argument that cobs have been around since 2000 is moot point as there were no models available at the time that could even come close to competing with the vero 18. It's also false in that cobs did not really exist on the consumer market. The closest you could find was offerings from roithner laser, for $$$$$.

So.... as for the heat... those cobs on my unit are runnig at 20W each, with an efficiency of about 38%, which means they generate about 12.4W of heat each. Those 10"x10" sinks with a thick base plate and 1 inch fins can handle the heat load no problem, and with a slight breeze stays nice and cool.

The reason they are spread apart is because I used a heat sink simulator to find the perfect distance between the heat sources to evenly distribute temperature!! It's called ENGINEERING

Remember, you are a merchant and I do not work for you. You can not ask me to stop scrutinizing you. Bad mouthing my superior product is not the way to go about getting me to stop bad mouthing your inferior one.

Peace bruh

Okay, first off, the datasheet for a bridgelux vero 18 3500k 80cri states that at 85C case temperature at at test current of 1050mA , the luminous efficacy is 112lm/W and 125lm/W at 25C. The 4 vero 18 running on that large heatsink are being underdriven at 700mA, which increases luminous efficacy significantly more. 125lm/W is higher than 60-70lm/w. There is no luck here, only good engineering.

http://www.bridgelux.com/wp-content/uploads/2013/10/DS32-Bridgelux-Vero-18-Datasheet.pdf

Your argument that cobs have been around since 2000 is moot point as there were no models available at the time that could even come close to competing with the vero 18. It's also false in that cobs did not really exist on the consumer market. The closest you could find was offerings from roithner laser, for $$$$$.

So.... as for the heat... those cobs on my unit are runnig at 20W each, with an efficiency of about 38%, which means they generate about 12.4W of heat each. Those 10"x10" sinks with a thick base plate and 1 inch fins can handle the heat load no problem, and with a slight breeze stays nice and cool.

The reason they are spread apart is because I used a heat sink simulator to find the perfect distance between the heat sources to evenly distribute temperature!! It's called ENGINEERING

Remember, you are a merchant and I do not work for you. You can not ask me to stop scrutinizing you. Bad mouthing my superior product is not the way to go about getting me to stop bad mouthing your inferior one.

Peace bruh

A single LED from Cree for example can reach lumens per watt of over 200.... With all the thermal and optical losses we are at 110 Lumens per watt with our system. with the setup you are showing your luck if you have 60-70LpW.

Take a look at the picture we uploaded. We have tested so many COBs , more than you know. And just an FYI this "COB technology" has been around since the year 2000.... Its far from new.

Even CREE COB is not something we want and we are a branding partner of theirs.

why do you have x4 80 watt COB so far away from one another? too much heat !!!

Please dont just claim stuff to the public with out true understanding. You can always give us a call or come to our factory and we are happy to explain...

Positivity

Well-Known Member

Well i like the video...

But I think you are way underplaying the effectiveness of cobs.

There are quite a few examples of diy lights that would outperform this light based on light spread alone.

I do applaud your enthusiasm though, and willingness to put yourself out there with a led light. It looks like a tough market..

The sun like spectrum....is nice. But if using individual diodes why not take advantage of that design by integrating complimentary spectrums. It seems unneccessary to seperate whites and use a pcb given the new tech advances.

For example if one led goes out..the whole board gets tossed? Its a bit wasteful..

It would be a good design cost-wise IF it were at HID prices. But not so much performance-wise.

This is the wrong website to compare those leds to the latest tech out. Those and subsequent generations have all been thoroughly tested already...albeit this white cluster is a different type design. I have a feeling you have already done a little white "sun like" spectrum research here.

But I think you are way underplaying the effectiveness of cobs.

There are quite a few examples of diy lights that would outperform this light based on light spread alone.

I do applaud your enthusiasm though, and willingness to put yourself out there with a led light. It looks like a tough market..

The sun like spectrum....is nice. But if using individual diodes why not take advantage of that design by integrating complimentary spectrums. It seems unneccessary to seperate whites and use a pcb given the new tech advances.

For example if one led goes out..the whole board gets tossed? Its a bit wasteful..

It would be a good design cost-wise IF it were at HID prices. But not so much performance-wise.

This is the wrong website to compare those leds to the latest tech out. Those and subsequent generations have all been thoroughly tested already...albeit this white cluster is a different type design. I have a feeling you have already done a little white "sun like" spectrum research here.

churchhaze

Well-Known Member

@Spectrum KIng LED , so now I have a few obvious questions.

If your powerful light is in a 4 inch diameter circle, why do other LED grow light compnaies that use quality individual leds (like area51 and apache tech) spread their individual leds out over a much larger area? Does it really dissipate 400W in such a small area? If so, you'd have to keep it pretty high up to get any decent light spread.

a 4 inch circle doesn't seem like it's taking advantage of splitting them apart so much as taking advantage of the readily available metal PCB with footprints for high quality crees.

For a product that uses genuine crees rather than shitty epistars, I can't see how you can dislike the vero and cxa3070 series so much, other than it cutting into profits.

If your powerful light is in a 4 inch diameter circle, why do other LED grow light compnaies that use quality individual leds (like area51 and apache tech) spread their individual leds out over a much larger area? Does it really dissipate 400W in such a small area? If so, you'd have to keep it pretty high up to get any decent light spread.

a 4 inch circle doesn't seem like it's taking advantage of splitting them apart so much as taking advantage of the readily available metal PCB with footprints for high quality crees.

For a product that uses genuine crees rather than shitty epistars, I can't see how you can dislike the vero and cxa3070 series so much, other than it cutting into profits.

Last edited: