ruwtz

Well-Known Member

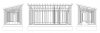

I built my own dedicated bespoke grow room in the back yard, and I have decided now is the time to share this work with RIU.

I dropped the best part of $10,000 on this new building: mostly because I wanted to future-proof the structure for other potential uses, and also because I pulled a city permit so everything is to code (ie. no cutting corners). The other reason is I am growing grade A top shelf, no filler and no cash crop, and I believe the finest product demands the finest facility. We building Ferraris here.

It has taken me 8 months from design through to completion, doing almost everything on my own. If you're interested in any of these steps, I'll show you how.

It has been incredibly hard work, I have sweated and I have bled for this, there have been some very tiny tears occasionally, and I have also thrown the towel in at least twice. But I got there and it is done now. As I complete the final phase of fitting out equipment there is HID light at the end of this tunnel, and I am about to commence my latest grow adventure.

I have ample pictures and descriptions of what I have done here and I am happy to share so long as there is interest. I will start brief to get this going. If anyone is interested in seeing more then please reply here and I will carry on.

I have just signed up here today to get involved in your community forum, as it has been incredibly helpful to me through planning my operation, and its time I added something back.

Peace all,

I dropped the best part of $10,000 on this new building: mostly because I wanted to future-proof the structure for other potential uses, and also because I pulled a city permit so everything is to code (ie. no cutting corners). The other reason is I am growing grade A top shelf, no filler and no cash crop, and I believe the finest product demands the finest facility. We building Ferraris here.

It has taken me 8 months from design through to completion, doing almost everything on my own. If you're interested in any of these steps, I'll show you how.

It has been incredibly hard work, I have sweated and I have bled for this, there have been some very tiny tears occasionally, and I have also thrown the towel in at least twice. But I got there and it is done now. As I complete the final phase of fitting out equipment there is HID light at the end of this tunnel, and I am about to commence my latest grow adventure.

I have ample pictures and descriptions of what I have done here and I am happy to share so long as there is interest. I will start brief to get this going. If anyone is interested in seeing more then please reply here and I will carry on.

I have just signed up here today to get involved in your community forum, as it has been incredibly helpful to me through planning my operation, and its time I added something back.

Peace all,

Last edited: