patrikantonius

Active Member

Hi guys. You may have noticed that I did a lot of research on LEDs in the past few weeks. Thanks to you guys, they have been very rewarding and I think I can finally build my own light.

I wanted something for a small space (0.25-0.4 m²), short, ideally for a SCROG. Obviously with the best performance per watt while keeping a reasonable price.

Here are the "ingredients"

The LEDs come from radiospares, heatsinks and drivers from China on ebay, PCBs from a local reseller. Total around 170 inc tax & shipping.

Total power (theoretical): 84.8W

34*2.45*0.680 = 56.6W (reds)

12*3.45*0.680 = 28.2W (whites/blues)

Why all Osrams? Its a purely personal choice. I had the opportunity to take all those LEDs from the same supplier so it was more convenient. I'd have got XP-E reds (in 625nm) and XP-G2 whites, along with the Osrams 660s if I was really seeking the best of the best.

LEDs will be mounted on star MCPCBs and glued to the heatsinks with thermal compound & epoxy. I will certainly use 120mm fans at max power but I'm not decided yet. In the beginning, I will wire both panels in parallel to one driver; passive cooling will be okay I guess.

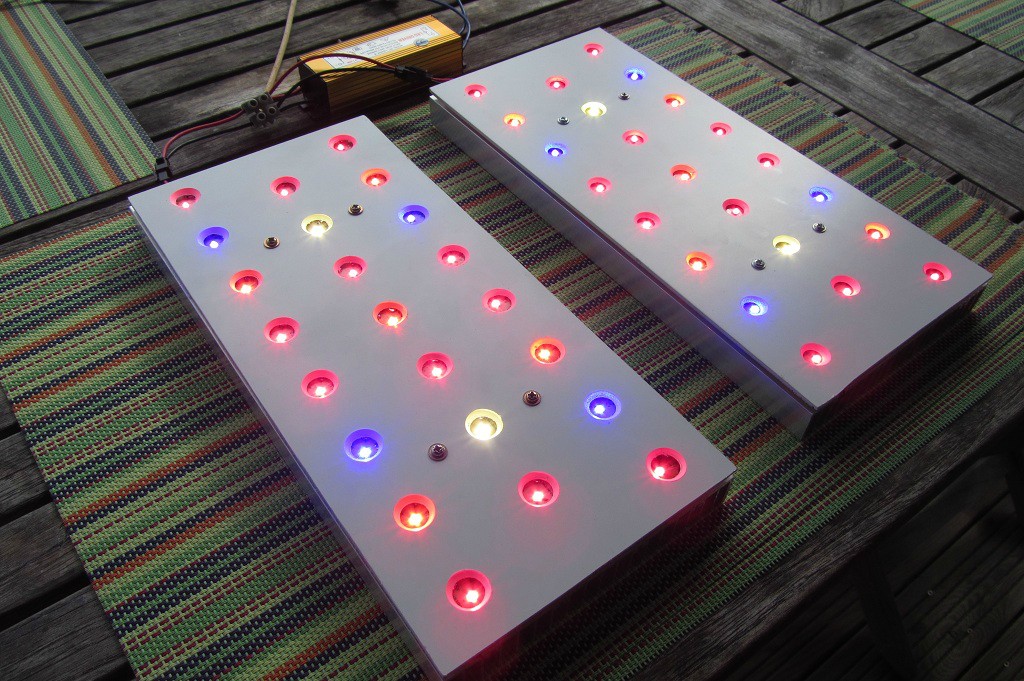

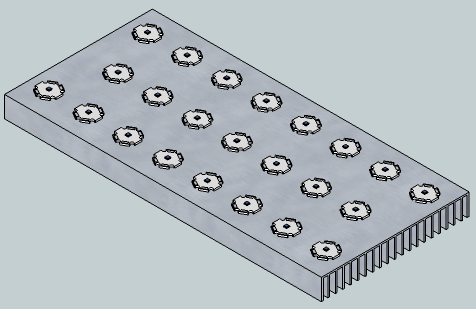

One panel (of the two)

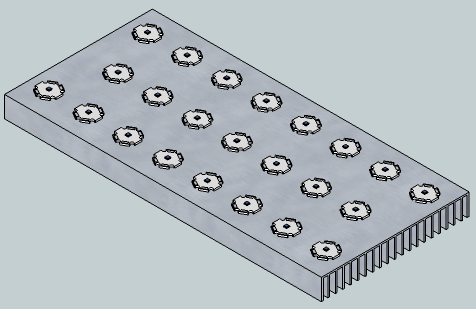

LEDs location

I have already received most parts, I'm still waiting for the PCBs to arrive but it should only take a couple of days. I will keep you updated.

See ya!

I wanted something for a small space (0.25-0.4 m²), short, ideally for a SCROG. Obviously with the best performance per watt while keeping a reasonable price.

Here are the "ingredients"

| 46 | LEDs |

| 24 | Osram Oslon SSL deep red (660nm), 80° |

| 10 | Osram Oslon SSL red (625nm), 80° |

| 8 | Osram Oslon SSL deep blue (450nm), 80° |

| 4 | Osram Oslon Square neutral white (4000k), 120° |

| 2 | Drivers 36-75v/0.68A (50W max) |

| 2 | Heatsinks 140*300*20(mm), 0.32m² surface each |

The LEDs come from radiospares, heatsinks and drivers from China on ebay, PCBs from a local reseller. Total around 170 inc tax & shipping.

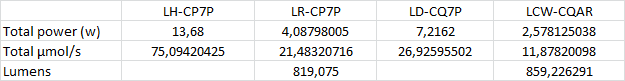

Total power (theoretical): 84.8W

34*2.45*0.680 = 56.6W (reds)

12*3.45*0.680 = 28.2W (whites/blues)

Why all Osrams? Its a purely personal choice. I had the opportunity to take all those LEDs from the same supplier so it was more convenient. I'd have got XP-E reds (in 625nm) and XP-G2 whites, along with the Osrams 660s if I was really seeking the best of the best.

LEDs will be mounted on star MCPCBs and glued to the heatsinks with thermal compound & epoxy. I will certainly use 120mm fans at max power but I'm not decided yet. In the beginning, I will wire both panels in parallel to one driver; passive cooling will be okay I guess.

One panel (of the two)

LEDs location

I have already received most parts, I'm still waiting for the PCBs to arrive but it should only take a couple of days. I will keep you updated.

See ya!