vahpor

Well-Known Member

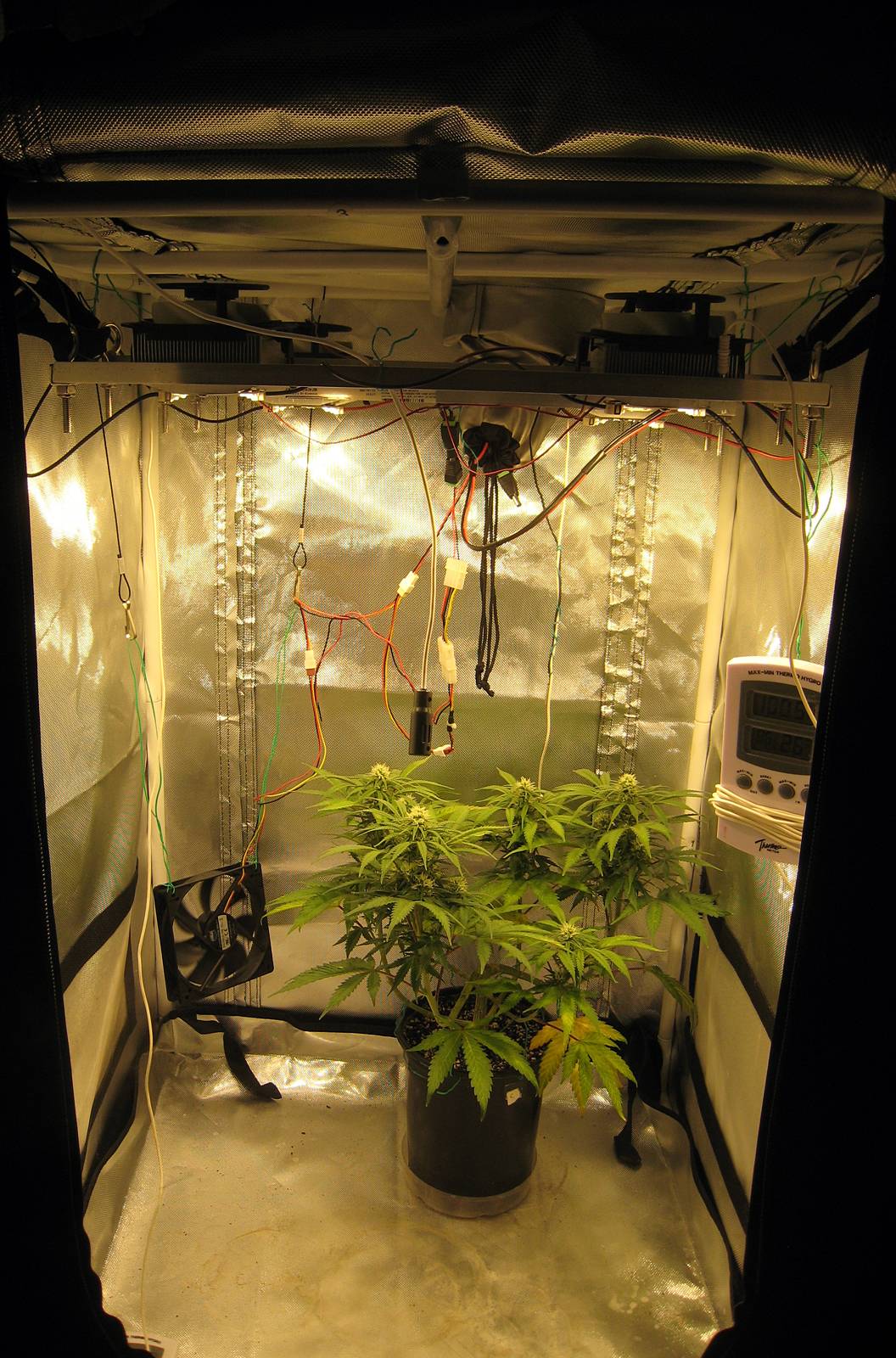

Just another guy jumping on this high efficiency COB bandwagon. I've been dabbling with some cheap-CN 100w chips for a bit, and seeing great results. I've ran a cheap-CN 180w UFO LED (92w draw) and wasn't all that impressed, lots of heat, required a large distance to canopy, lack of density/size due to distance from light, not dimmable. In the pic below I'm running each 100w chip between 30 and 50w, I've had to turn them down due to heat issues when I fired up the UFO..

I'm flowering in a 2x2x3' mini-tent (because thats what I have space for).

I will be adding a full tent DIY SCROG insert (1/2" PVC and some elbows), and be running a single plant in a 5 gal (or larger??) Smart Pot on my next flower run.

My build:

1x HLG-185H-C1400B (w/ 100k potenti & knob)

4x CXB3590 3000k CB (top bin)

4x Ideal holders

4x Arctic Alpine 64 GT Rev 2 (80mm fan, 70w dissipation)

Arctic Silver 3 TIM

Drilled and tapped heatsink, 3mm screws.

Frame designed from 1/2" x 1/20" thick angle alu. and some 1/4" eye bolts (would go 1 size smaller with this 1/2" alu next time). 2 chips/hs/fans per 'light rig'; 18" x ~2 3/4". The heatsinks will be adjustable and slide inwards/outwards as needed. Maybe useful if I use the light in a larger space and need more coverage?

I plan to run the light at lower amperage, hoping to push 50-55% efficiency or so @ 110-130w total. Its my understanding 700ma is 58% with this 3000k CB bin?

I spent the day beginning the physical build. Got the first frame built.

And the fans wired up to a 6v, 250mA source. Still not sure if this PSU will cut it, I tested draw on 1 fan and then 2 in parallel. 67mA for one, ~130mA for two. Voltage is at exactly 6.00v with two fans, w/o a load it read ~6.16v, so maybe with four the voltage will droop further, and keep me within the 250mA, but its likely too close for reliability. I will likely source a MW 8w 5v, but really would like to find a 6v to be sure the fans start. Maybe a universal @ 7.5v?

I drilled, tapped, and installed two chips thus far. Its taking me quite a while to drill the sinks, the tapping goes well. I'm just going very slow RPM (set your drill at its lowest speed, and also use very low pressure on the trigger), very low pressure applied to bit (the weight of the drill), and using a lot of WD40 for lube. No broken bits or taps! I do need to get a T handle for my taps, a crescent wrench isn't the smoothest way to tap a hole this size..

No pics, but I also installed wiring for this pair of COBs, I wish I had solid wire, but got the 18 gauge stranded to work OK. Soldered a AC plug onto my driver too.

Waiting on 100k pots.

Waiting on new hacksaw blades to finish cutting my alu for my 2nd light rig.

I'm hoping to get a couple more heatsinks drilled, tapped, and COBs installed in the mean time. Then have all the wiring completed and ready to install in light frame. Maybe running by end of week!?

Very excited about this COB lighting and its efficiency. These large grows/warehouses are going to have to wake up to the fact that running thousands of 1000+w HIDs aren't going to be sustainable as the cannabis movement and industry grows and develops further. We need to get this tech in these large grow ops, and make them aware. I hope a large LED builder can get behind this and meet demand.

I'm flowering in a 2x2x3' mini-tent (because thats what I have space for).

I will be adding a full tent DIY SCROG insert (1/2" PVC and some elbows), and be running a single plant in a 5 gal (or larger??) Smart Pot on my next flower run.

My build:

1x HLG-185H-C1400B (w/ 100k potenti & knob)

4x CXB3590 3000k CB (top bin)

4x Ideal holders

4x Arctic Alpine 64 GT Rev 2 (80mm fan, 70w dissipation)

Arctic Silver 3 TIM

Drilled and tapped heatsink, 3mm screws.

Frame designed from 1/2" x 1/20" thick angle alu. and some 1/4" eye bolts (would go 1 size smaller with this 1/2" alu next time). 2 chips/hs/fans per 'light rig'; 18" x ~2 3/4". The heatsinks will be adjustable and slide inwards/outwards as needed. Maybe useful if I use the light in a larger space and need more coverage?

I plan to run the light at lower amperage, hoping to push 50-55% efficiency or so @ 110-130w total. Its my understanding 700ma is 58% with this 3000k CB bin?

I spent the day beginning the physical build. Got the first frame built.

And the fans wired up to a 6v, 250mA source. Still not sure if this PSU will cut it, I tested draw on 1 fan and then 2 in parallel. 67mA for one, ~130mA for two. Voltage is at exactly 6.00v with two fans, w/o a load it read ~6.16v, so maybe with four the voltage will droop further, and keep me within the 250mA, but its likely too close for reliability. I will likely source a MW 8w 5v, but really would like to find a 6v to be sure the fans start. Maybe a universal @ 7.5v?

I drilled, tapped, and installed two chips thus far. Its taking me quite a while to drill the sinks, the tapping goes well. I'm just going very slow RPM (set your drill at its lowest speed, and also use very low pressure on the trigger), very low pressure applied to bit (the weight of the drill), and using a lot of WD40 for lube. No broken bits or taps! I do need to get a T handle for my taps, a crescent wrench isn't the smoothest way to tap a hole this size..

No pics, but I also installed wiring for this pair of COBs, I wish I had solid wire, but got the 18 gauge stranded to work OK. Soldered a AC plug onto my driver too.

Waiting on 100k pots.

Waiting on new hacksaw blades to finish cutting my alu for my 2nd light rig.

I'm hoping to get a couple more heatsinks drilled, tapped, and COBs installed in the mean time. Then have all the wiring completed and ready to install in light frame. Maybe running by end of week!?

Very excited about this COB lighting and its efficiency. These large grows/warehouses are going to have to wake up to the fact that running thousands of 1000+w HIDs aren't going to be sustainable as the cannabis movement and industry grows and develops further. We need to get this tech in these large grow ops, and make them aware. I hope a large LED builder can get behind this and meet demand.

Last edited: