Fadedawg

Well-Known Member

Vacuum distillation

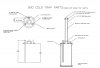

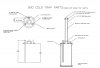

For those of ya'll wishing to vacuum distill your butane to remove any heavier components, before using it for extraction, here is a design for the cold trap that we will be using as a test sled, to not only vacuum distill the butane, for further polish filtering it through a Bentonite, zeolite, etc, column.

The way it works, is that the butane is injected into the cold trap as a liquid and pumped off as a vapor, leaving behind those things with a higher boiling point.

I set my cold trap in 85F water. You can do it without setting the trap in warm water, but as the butane boils off under vacuum, the transition from liquid to vapor, liberates the heat of vaporization, and plunges the temperature of the pool of butane to below its boiling point, so the process moves in starts and stops.

The next Alkane boils at about 36.1C/98.6F, at atmospheric pressure, so it is important to not heat the pot much beyond about 85F. The thermometer in the cold trap lid will tell you at what temperature your butane pool is during the cycle.

It is also important to not recover the butane below where the compound pressure gauge reads zero pressure, zero vacuum, or 14.7 PSIA.

PSIA is pounds per square inch absolute, which starts at absolute zero, without the weight of the atmosphere (at full vacuum). The atmosphere weighs 14.7 pounds per square inch, which is what a 1" column of mercury 29.92" tall weighs.

We do this operation outside and recommend that everyone do the same. Even though it is ostensibly a fully enclosed system, what if there is a leak or something goes wrong, goes wrong, goes wrong..........?

I recommend that you read and heed the thread on Butane Safety, before embarking on this journey. http://skunkpharmresearch.com/butane-safety/

Pull a full vacuum on the empty 50# refrigerant recovery tank for the first time, and valve it off.

Attach the pressure gauge to the cold trap via 1/4" refrigerant hose and pull a full vacuum on the trap, and valve it off, before assembling the system.

To vacuum distill using the cold trap, attach a 1/4" refrigerant hose to the inlet of the cold trap, and the other end to either an LP-5 tank of n-Butane, or to a can tapper, preferably with a ball valve attached at the tapper.

Attach the 1/2" outlet hose to the top of the filter section and the other end goes to the inlet of a refrigerant recovery pump.

We've used a couple of inexpensive brands for this purpose, namely the Appion G-5 twin and the CPS T-21, but neither are not rated by the manufacturer for butane, because they are not explosion proof should a leak occur.

Our larger commercial sized Mk V Terpenator will have the more expensive Caresaver Universal, or a Haskell pneumatic refrigerant recovery pump as an option, that are rated for flammable refrigerants, such as R-600 (n-Butane).

Depending on your situation, you should pick an option that fits your needs and safety needs.

The other hose goes to the red liquid dip tube valve on the 50# refrigerant recovery tank, which is sitting in an ice bath. If you really want to fly, set it in a denatured alcohol bath, with chunks of dry ice dropping the temperature to -70F or so.

Start the refrigerant recovery pump and the open the red valve on the refrigerant recovery tank, as well as the outlet valve on the cold trap.

If you are using an LP-5 tank of n-Butane, set the tank on a refrigerant scale and weigh it. Record the weight and push tare on the scale.

Open the inlet valve on the cold trap slowly and transfer about two liters of butane, or about 1146 grams, 2.5 lbs. Close the inlet valve.

The pressure gauge will have gone from -29.92" Hg vacuum, to positive pressure in the range of 10 to 30 psi. Watch until the pressure gauge drops to zero pressure, zero vacuum, and then load another 2 liters for distillation.

If you are using canned butane and a can tapper, close the valve at the can tapper, and open the inlet valve on the trap fully.

Tap the can and open the ball valve at the tapper. The pressure will rise from zero, to positive pressure. When the recovery pump lowers the pressure back to zero pressure, zero vacuum, close the valve at the tapper and tap a new can.

Open the valve to drain that can as well, and continue this cycle until all cans are empty.

Once you have emptied the LP-5 or the cans, when the pressure reaches zero again, close all valves and turn off the recovery pump.

Disconnect the hoses from the trap and open all valves to let it breath.

Remove the lid to the cold trap to remove the materials removed from the butane, and clean the trap with denatured alcohol for the next batch of butane.

For those of ya'll wishing to vacuum distill your butane to remove any heavier components, before using it for extraction, here is a design for the cold trap that we will be using as a test sled, to not only vacuum distill the butane, for further polish filtering it through a Bentonite, zeolite, etc, column.

The way it works, is that the butane is injected into the cold trap as a liquid and pumped off as a vapor, leaving behind those things with a higher boiling point.

I set my cold trap in 85F water. You can do it without setting the trap in warm water, but as the butane boils off under vacuum, the transition from liquid to vapor, liberates the heat of vaporization, and plunges the temperature of the pool of butane to below its boiling point, so the process moves in starts and stops.

The next Alkane boils at about 36.1C/98.6F, at atmospheric pressure, so it is important to not heat the pot much beyond about 85F. The thermometer in the cold trap lid will tell you at what temperature your butane pool is during the cycle.

It is also important to not recover the butane below where the compound pressure gauge reads zero pressure, zero vacuum, or 14.7 PSIA.

PSIA is pounds per square inch absolute, which starts at absolute zero, without the weight of the atmosphere (at full vacuum). The atmosphere weighs 14.7 pounds per square inch, which is what a 1" column of mercury 29.92" tall weighs.

We do this operation outside and recommend that everyone do the same. Even though it is ostensibly a fully enclosed system, what if there is a leak or something goes wrong, goes wrong, goes wrong..........?

I recommend that you read and heed the thread on Butane Safety, before embarking on this journey. http://skunkpharmresearch.com/butane-safety/

Pull a full vacuum on the empty 50# refrigerant recovery tank for the first time, and valve it off.

Attach the pressure gauge to the cold trap via 1/4" refrigerant hose and pull a full vacuum on the trap, and valve it off, before assembling the system.

To vacuum distill using the cold trap, attach a 1/4" refrigerant hose to the inlet of the cold trap, and the other end to either an LP-5 tank of n-Butane, or to a can tapper, preferably with a ball valve attached at the tapper.

Attach the 1/2" outlet hose to the top of the filter section and the other end goes to the inlet of a refrigerant recovery pump.

We've used a couple of inexpensive brands for this purpose, namely the Appion G-5 twin and the CPS T-21, but neither are not rated by the manufacturer for butane, because they are not explosion proof should a leak occur.

Our larger commercial sized Mk V Terpenator will have the more expensive Caresaver Universal, or a Haskell pneumatic refrigerant recovery pump as an option, that are rated for flammable refrigerants, such as R-600 (n-Butane).

Depending on your situation, you should pick an option that fits your needs and safety needs.

The other hose goes to the red liquid dip tube valve on the 50# refrigerant recovery tank, which is sitting in an ice bath. If you really want to fly, set it in a denatured alcohol bath, with chunks of dry ice dropping the temperature to -70F or so.

Start the refrigerant recovery pump and the open the red valve on the refrigerant recovery tank, as well as the outlet valve on the cold trap.

If you are using an LP-5 tank of n-Butane, set the tank on a refrigerant scale and weigh it. Record the weight and push tare on the scale.

Open the inlet valve on the cold trap slowly and transfer about two liters of butane, or about 1146 grams, 2.5 lbs. Close the inlet valve.

The pressure gauge will have gone from -29.92" Hg vacuum, to positive pressure in the range of 10 to 30 psi. Watch until the pressure gauge drops to zero pressure, zero vacuum, and then load another 2 liters for distillation.

If you are using canned butane and a can tapper, close the valve at the can tapper, and open the inlet valve on the trap fully.

Tap the can and open the ball valve at the tapper. The pressure will rise from zero, to positive pressure. When the recovery pump lowers the pressure back to zero pressure, zero vacuum, close the valve at the tapper and tap a new can.

Open the valve to drain that can as well, and continue this cycle until all cans are empty.

Once you have emptied the LP-5 or the cans, when the pressure reaches zero again, close all valves and turn off the recovery pump.

Disconnect the hoses from the trap and open all valves to let it breath.

Remove the lid to the cold trap to remove the materials removed from the butane, and clean the trap with denatured alcohol for the next batch of butane.