Renfro

Well-Known Member

Hey folks, I didn't know if I should put this here or in grow room design and setup so I chose here.

My flowering room that run during the daytime gets a little warmer than I wish when it's 90+ outside. I have two rooms on a flip so I can't run this room at night.

I currently have about 10kW of HPS in there with 6 overhead DE HPS lights as the primary light source, the rest is side lighting (vertical HPS)

So I am building these 6 LED lights to replace the DE HPS lights.

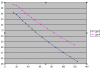

I intend to use Luminous CXM-22 Gen 4 3500K 90 CRI COBS. Here is a chart showing the gen 4 compared to some other cobs.

I will be using 12 cobs per light and I will drive them at 60 watts each using Meanwell HLG-240H-54B drivers. The DC output from the drivers totals 720 watts, the input wattage is about 760.

The lights will be dimmable and I intend to dim each driver (row) individually, may be overkill but it's not that much more cost.

BJB Holders, 133mm pin fin heatsinks, bunch of wagos, Angelina Reflectors for BJB Holders, Arctic MX4, wire...

I am planning to experiment with a DROK Power Meter so I can see what the numbers are for dimming. This again may be overkill. I will experiment and see if I can run the positive output conductors from all three drivers thru the sensor coil on the DROK and have it accumulate the readings. That would be what I am after and if it works I will order 5 more of those and some project boxes to mount them in and put the dimmer knobs on. I am not concerned with monitoring the power on the AC side, just the DC output.

I intend to purchase an Apogee MQ-500 meter so I can tune the light, COB spacing and dimming.

I will be using these lights over a 4x4 foot area but the plants do get a little wider so I allowed a few extra watts. If I calculate by 16 square feet I get 45 watts per sqft. If I decide I want to go bigger in the future I could add another row of cobs and another driver but lets see what this does as I really would like to believe that I can replace 1150 watts of HPS with 760 watts of LED while reducing the heat load by at least a ton.

I am considering a frame built of aluminum T- Slot channel so I can easily adjust the cob spacing. I may only do this on the first light so I can tune the COB spacing to get the light spread how I want it. If the cost isn't insane it would be cool to build them all that way but chances are the other 5 lights would be made of aluminum angle and pop rivets. Probably save a couple bills a light.

I am thinking of starting with the outer cobs being about 40 - 42 inches apart, any thoughts on that for a 48 x 48 inch coverage?

So I have a lot on my plate with this project. Any ideas, thoughts, positive motivation and whatnot are welcomed. Please tag along for the ride. I am ordering the first round of parts tomorrow from @CobKits so we can get this party started and build some lights!

My flowering room that run during the daytime gets a little warmer than I wish when it's 90+ outside. I have two rooms on a flip so I can't run this room at night.

I currently have about 10kW of HPS in there with 6 overhead DE HPS lights as the primary light source, the rest is side lighting (vertical HPS)

So I am building these 6 LED lights to replace the DE HPS lights.

I intend to use Luminous CXM-22 Gen 4 3500K 90 CRI COBS. Here is a chart showing the gen 4 compared to some other cobs.

I will be using 12 cobs per light and I will drive them at 60 watts each using Meanwell HLG-240H-54B drivers. The DC output from the drivers totals 720 watts, the input wattage is about 760.

The lights will be dimmable and I intend to dim each driver (row) individually, may be overkill but it's not that much more cost.

BJB Holders, 133mm pin fin heatsinks, bunch of wagos, Angelina Reflectors for BJB Holders, Arctic MX4, wire...

I am planning to experiment with a DROK Power Meter so I can see what the numbers are for dimming. This again may be overkill. I will experiment and see if I can run the positive output conductors from all three drivers thru the sensor coil on the DROK and have it accumulate the readings. That would be what I am after and if it works I will order 5 more of those and some project boxes to mount them in and put the dimmer knobs on. I am not concerned with monitoring the power on the AC side, just the DC output.

I intend to purchase an Apogee MQ-500 meter so I can tune the light, COB spacing and dimming.

I will be using these lights over a 4x4 foot area but the plants do get a little wider so I allowed a few extra watts. If I calculate by 16 square feet I get 45 watts per sqft. If I decide I want to go bigger in the future I could add another row of cobs and another driver but lets see what this does as I really would like to believe that I can replace 1150 watts of HPS with 760 watts of LED while reducing the heat load by at least a ton.

I am considering a frame built of aluminum T- Slot channel so I can easily adjust the cob spacing. I may only do this on the first light so I can tune the COB spacing to get the light spread how I want it. If the cost isn't insane it would be cool to build them all that way but chances are the other 5 lights would be made of aluminum angle and pop rivets. Probably save a couple bills a light.

I am thinking of starting with the outer cobs being about 40 - 42 inches apart, any thoughts on that for a 48 x 48 inch coverage?

So I have a lot on my plate with this project. Any ideas, thoughts, positive motivation and whatnot are welcomed. Please tag along for the ride. I am ordering the first round of parts tomorrow from @CobKits so we can get this party started and build some lights!