You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Most ideal heatsink temp

- Thread starter Durei

- Start date

Anyone?

Temperature I am reading is 35 degrees of heatsink after 1 hour of operation. Driven at 1.7a with a lens covering the cob, fan I'm using is around 23cfm. I have tested it with a 30cfm fan, temperature was slightly lower at 33 degrees but the noise of that fan was too loud.

Is 35 degrees an acceptable and efficient heatsink temperature?

Temperature I am reading is 35 degrees of heatsink after 1 hour of operation. Driven at 1.7a with a lens covering the cob, fan I'm using is around 23cfm. I have tested it with a 30cfm fan, temperature was slightly lower at 33 degrees but the noise of that fan was too loud.

Is 35 degrees an acceptable and efficient heatsink temperature?

SupraSPL

Well-Known Member

Yes 35C is OK, if it is the hottest part of the heatsink you can measure without the light of the COB interfering. There is not much to be gained by trying to run cooler, especially when it comes to COBs and even more so when it comes to Veros. Depending on your setup, running the fan harder may actually decrease the overall system efficiency.

Greengenes707

Well-Known Member

Ambient(what ever that is for you) for standard air cooling(active or passive) is the best possible temps. The closer to ambient the better. The upper end I'd say don't go over 50c for heatsink temps cause Tc will be even higher. Your seems to be doing great.

If we bring up liquid cooling and refrigerant...lower than ambient is now the goal for some.

I can say that no one has ever over done their cooling to negatively effect performance. Some may spend a little much on it...but he performance is great.

If we bring up liquid cooling and refrigerant...lower than ambient is now the goal for some.

I can say that no one has ever over done their cooling to negatively effect performance. Some may spend a little much on it...but he performance is great.

SupraSPL

Well-Known Member

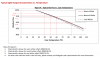

Vero 29 V2.0 temp droop chart

If the ambient temp in the tent is is approx 25C (77F), when the COBs are driven soft (~25W) we might be able to achieve a Tj of 30C (TC ~27C) and almost no temp droop whatsoever. Run at medium power (~50W), Tj 50-60C (Tc 35-40C) is a fair target range and still no significant loss of efficiency.

Run mid-hard (70-100W) or run with somewhat insufficient cooling could lead to a Tj of 100C (Tc 60-70C) with a temp droop of less than 10%. Not ideal but should still have very good output. May experience some lumen depreciation over time at these temps.

The Optic Lighting Vero 29 200W lamp tested about 3% temp droop, running each Vero29 2.0 at 2.15A (80W). I measured TC 40-45C. They did not go overboard with cooling but achieved it efficiently using CPU cooler style and running low RPM fans at 12V. So I think any COB should be able to come in at or under 4% temp droop without too much trouble.

If the ambient temp in the tent is is approx 25C (77F), when the COBs are driven soft (~25W) we might be able to achieve a Tj of 30C (TC ~27C) and almost no temp droop whatsoever. Run at medium power (~50W), Tj 50-60C (Tc 35-40C) is a fair target range and still no significant loss of efficiency.

Run mid-hard (70-100W) or run with somewhat insufficient cooling could lead to a Tj of 100C (Tc 60-70C) with a temp droop of less than 10%. Not ideal but should still have very good output. May experience some lumen depreciation over time at these temps.

The Optic Lighting Vero 29 200W lamp tested about 3% temp droop, running each Vero29 2.0 at 2.15A (80W). I measured TC 40-45C. They did not go overboard with cooling but achieved it efficiently using CPU cooler style and running low RPM fans at 12V. So I think any COB should be able to come in at or under 4% temp droop without too much trouble.

Last edited:

Thanks for all those replies. If I measure the base of the heatsink (thick aluminium where the cob is attached) I measure the given temps. If I measure in the middle of the fins the temp is a little higher.

I was just curious about ideal heatsink temp for cobs in our purpose. The whole light is running pretty cool now with this sink/fan combo. In most grow rooms there is plenty of other air movement which will cool the lights aswell.

I was just curious about ideal heatsink temp for cobs in our purpose. The whole light is running pretty cool now with this sink/fan combo. In most grow rooms there is plenty of other air movement which will cool the lights aswell.

robincnn

Well-Known Member

lipsI will try that, didn't know. It seems to be accurate though, I can touch the sink with my lips without having the urge to take em off

.. not sure

.. not sure

I use something like this

http://www.ebay.com/itm/Nice-Non-Co...Temperature-Thermometer-Gun-FO-/291326656758?

The IR gun has emissivity default as 0.95. resets to 0.95 every time i power it on. Turn it to 0.25 or use black tape like this

It should be in the manual. it might even have a list of emissivity values for different materials.

I used it on the top one (regular heatsink, non anodized) and saw temp difference of 20 degrees on the black tape vs shinny part of heatsink.

I used it on the top one (regular heatsink, non anodized) and saw temp difference of 20 degrees on the black tape vs shinny part of heatsink.