Renfro

Well-Known Member

Ok, I am going to do a little cost analysis looking at setting up a new commercial grow and I will show you why going with quality LED is a no brainer due to the rapid return on investment (ROI) and long term savings. I just did a tent run with LED and I know that I can produce the same or better yields per square foot with LED at 600 watts vs HPS at 1000 watts. Now I am looking at a setup with a lot of lights and was doing math to see what lighting I want to run.

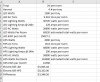

Lets make a few variables for this project:

Electrical Cost per kWh = $0.20

LED Fixture Cost = $800 (Timber Redwood VS)

HPS Fixture Cost = $300 (1000 watt HPS)

Lets say for the sake of this project that those prices get lights that produce the same yield per square foot.

Lets value the HPS lights at 5000 btu/hr each

Lets value the LED lights at about 2400 btu/hr each

Lets do a flowering room (12/12) with 48 lights

HPS we need 20 tons of AC

LED we need 9.6 tons of AC (10 tons)

So we spend twice as much on buying AC for the HPS setup and a little over twice as much for the LED lights vs HPS.

LED Lights = $38400

HPS Lights = $14400

LED AC = $10000

HPS AC = $20000

So for the HPS we pay $34,400 and LED we pay $48,400, a difference of $14,000.

Now lets math in electrical savings and we will cut the power bill lets say by a very conservative figure of 40% ish due to the lesser energy usage on AC and lighting and we are easily saving around $3300 per month on electrical if we go with LED. Did a bunch of mathematical gyrations in excel to get some estimates and I believe them to be within 10% assuming the $0.20 cost per kWh.

So at $3300 per month we can make up the $14,000 difference in startup cost in the first 17 weeks worth of electrical savings (4.25 months). After that we are basically making $3300 a month more profit, so in this case around $25,575 extra profit in the first year and $39,600 added profit in subsequent years, more as energy costs rise.

Even with my rough figures on costs and such you definitely get paid back within a year. Even with lower electrical costs. I know I can get the HPS lights cheaper but I also can figure on a discount on the LED in such quantity.

In the end I think the error rate on the variables sorta evens out in the wash and the case is overwhelming to go with LED provided you can get the same yields and quality. We also probably save even more on AC since we need to run the room warmer due to leaf surface temperatures and the lack of IR.

I didn't get into CMH here because I see it as sort of a middle ground and a rather gray area when it comes to yield and heat production. I rather not even bother with trying to run those numbers in this particular thought experiment.

There is no doubt in my mind that I will go with LED when I do my commercial building here soon as I have already proven to myself that I can achieve the same or better yield per square foot and same or better quality with LED. I never thought I would be saying that, been hard core HPS all my life. Times are a changing!

Sorry for my rambling... peace out!

Lets make a few variables for this project:

Electrical Cost per kWh = $0.20

LED Fixture Cost = $800 (Timber Redwood VS)

HPS Fixture Cost = $300 (1000 watt HPS)

Lets say for the sake of this project that those prices get lights that produce the same yield per square foot.

Lets value the HPS lights at 5000 btu/hr each

Lets value the LED lights at about 2400 btu/hr each

Lets do a flowering room (12/12) with 48 lights

HPS we need 20 tons of AC

LED we need 9.6 tons of AC (10 tons)

So we spend twice as much on buying AC for the HPS setup and a little over twice as much for the LED lights vs HPS.

LED Lights = $38400

HPS Lights = $14400

LED AC = $10000

HPS AC = $20000

So for the HPS we pay $34,400 and LED we pay $48,400, a difference of $14,000.

Now lets math in electrical savings and we will cut the power bill lets say by a very conservative figure of 40% ish due to the lesser energy usage on AC and lighting and we are easily saving around $3300 per month on electrical if we go with LED. Did a bunch of mathematical gyrations in excel to get some estimates and I believe them to be within 10% assuming the $0.20 cost per kWh.

So at $3300 per month we can make up the $14,000 difference in startup cost in the first 17 weeks worth of electrical savings (4.25 months). After that we are basically making $3300 a month more profit, so in this case around $25,575 extra profit in the first year and $39,600 added profit in subsequent years, more as energy costs rise.

Even with my rough figures on costs and such you definitely get paid back within a year. Even with lower electrical costs. I know I can get the HPS lights cheaper but I also can figure on a discount on the LED in such quantity.

In the end I think the error rate on the variables sorta evens out in the wash and the case is overwhelming to go with LED provided you can get the same yields and quality. We also probably save even more on AC since we need to run the room warmer due to leaf surface temperatures and the lack of IR.

I didn't get into CMH here because I see it as sort of a middle ground and a rather gray area when it comes to yield and heat production. I rather not even bother with trying to run those numbers in this particular thought experiment.

There is no doubt in my mind that I will go with LED when I do my commercial building here soon as I have already proven to myself that I can achieve the same or better yield per square foot and same or better quality with LED. I never thought I would be saying that, been hard core HPS all my life. Times are a changing!

Sorry for my rambling... peace out!