Jellypowered

Well-Known Member

Hey all!

Hopefully this is the right place.

I need help choosing a driver, I don't want to use a power supply and buck converter, I'd like streamlined goodness.

An 84 LED panel, custom made by me.

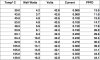

Using these LEDS:

Looking at some information online,

A single string of series wired LEDs, the total voltage is the sum of all LEDS in series.

So 7 leds at 6.3v should come to 44.1v

With Parallel you add all the current together.

If i'm driving at 150ma, with 12 strings in parallel, that should be 1800ma.

So, If i'm learning anything, I need a power supply that will output

44.1v @ 1800ma. per board? Technically, if I add more than one board, the MA requirement goes up by 1800ma each time?

I was thinking about using the meanwell LPF-90-42 or LPF-90-48, (they also make PWM versions)

If I use the LPF-90-42 will the output of 42v hurt my performance in any way? I need at least 44.1 based on calculations.

With that being said, would the LPF-90-48 hurt my LEDS being that it's putting out 48v?

Thanks for any info, I'm pretty new to LEDS so be kind but blunt.

Edit: found Sosen SS-100H-48 100 Watt LED Driver 36-48V Output 2100mA Constant Current as well. I don't know which one to use lol.

Jelly

Hopefully this is the right place.

I need help choosing a driver, I don't want to use a power supply and buck converter, I'd like streamlined goodness.

An 84 LED panel, custom made by me.

Using these LEDS:

Looking at some information online,

A single string of series wired LEDs, the total voltage is the sum of all LEDS in series.

So 7 leds at 6.3v should come to 44.1v

With Parallel you add all the current together.

If i'm driving at 150ma, with 12 strings in parallel, that should be 1800ma.

So, If i'm learning anything, I need a power supply that will output

44.1v @ 1800ma. per board? Technically, if I add more than one board, the MA requirement goes up by 1800ma each time?

I was thinking about using the meanwell LPF-90-42 or LPF-90-48, (they also make PWM versions)

If I use the LPF-90-42 will the output of 42v hurt my performance in any way? I need at least 44.1 based on calculations.

With that being said, would the LPF-90-48 hurt my LEDS being that it's putting out 48v?

Thanks for any info, I'm pretty new to LEDS so be kind but blunt.

Edit: found Sosen SS-100H-48 100 Watt LED Driver 36-48V Output 2100mA Constant Current as well. I don't know which one to use lol.

Jelly

Last edited: