DeMoNeye

Well-Known Member

Hi,

I've got a 400w bulb running in a glass tube enclosed shade...

Every change from veg/flower/veg/flower/repeat I have to pull the ducting off, change the bulb and then refit the ducting. Fiddly job each time and end of the ducting is getting shorter and shorter as it wears.

Does anyone know if there a collar or anything that I could use as an easy connection that can be connected/reconnected without much hassle.

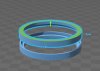

I think my only option is either speak nicely to an engineer with access to a lathe (anyone in the UK that can help me?) or design it myself and get something 3d printed.

I've got a 400w bulb running in a glass tube enclosed shade...

Every change from veg/flower/veg/flower/repeat I have to pull the ducting off, change the bulb and then refit the ducting. Fiddly job each time and end of the ducting is getting shorter and shorter as it wears.

Does anyone know if there a collar or anything that I could use as an easy connection that can be connected/reconnected without much hassle.

I think my only option is either speak nicely to an engineer with access to a lathe (anyone in the UK that can help me?) or design it myself and get something 3d printed.