Justin Eterovich

Member

Hey guys and gals,

Really glad I found this forum. Have been watching lots of DIY videos from the likes of growmau5 and ChilLED and have inspired me to make my own. Pretty much all parts are from RapidLED, thanks for your guys help!

I am still pretty new to the LED community so please feel free to comment/askQ/answer Q's and tell me im full of it.

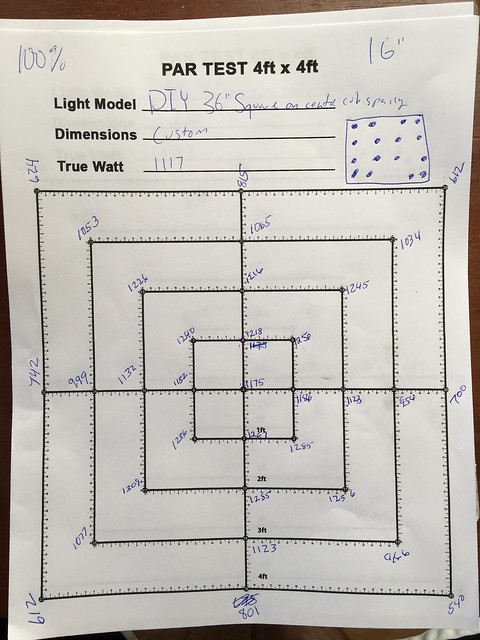

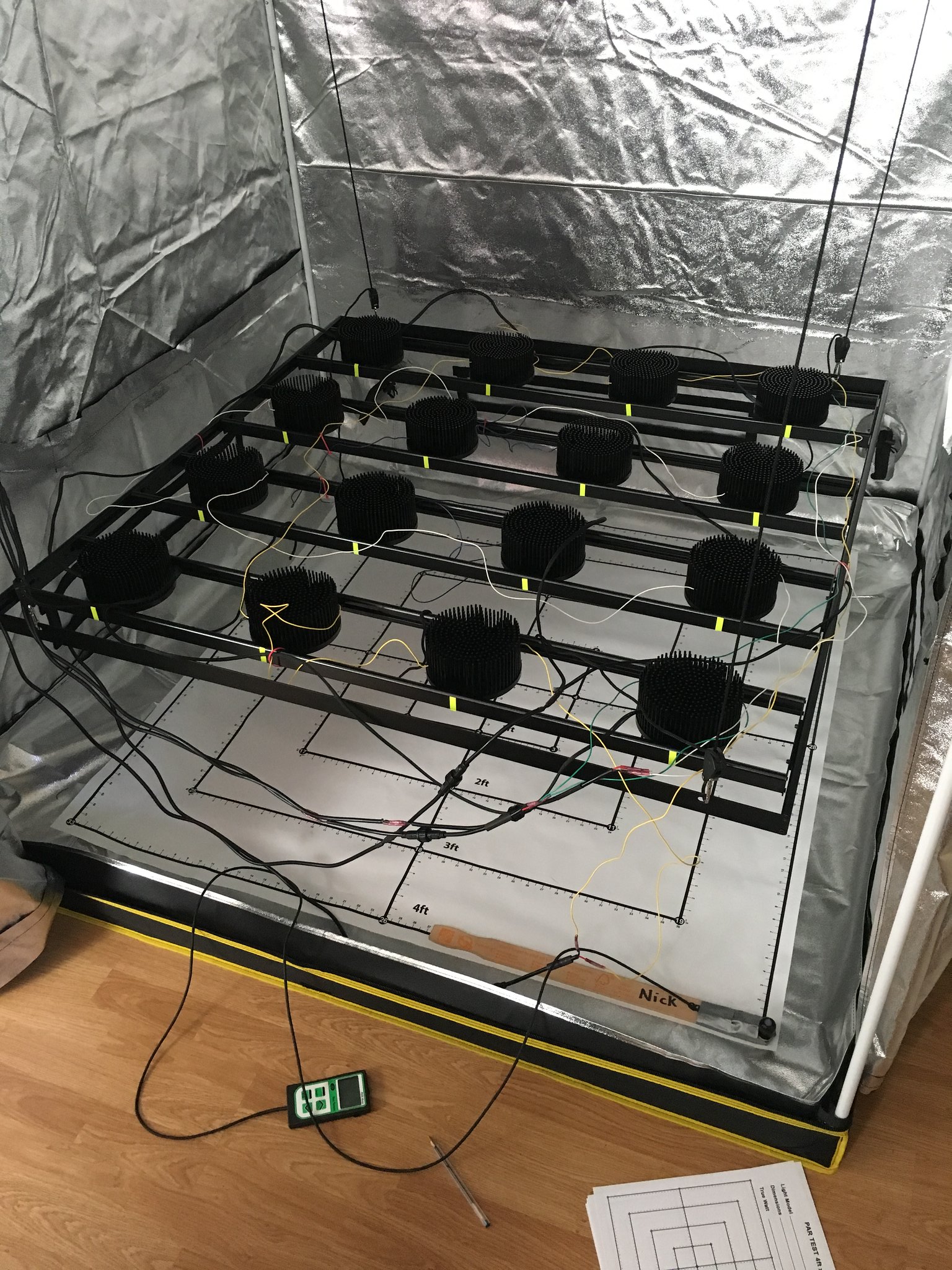

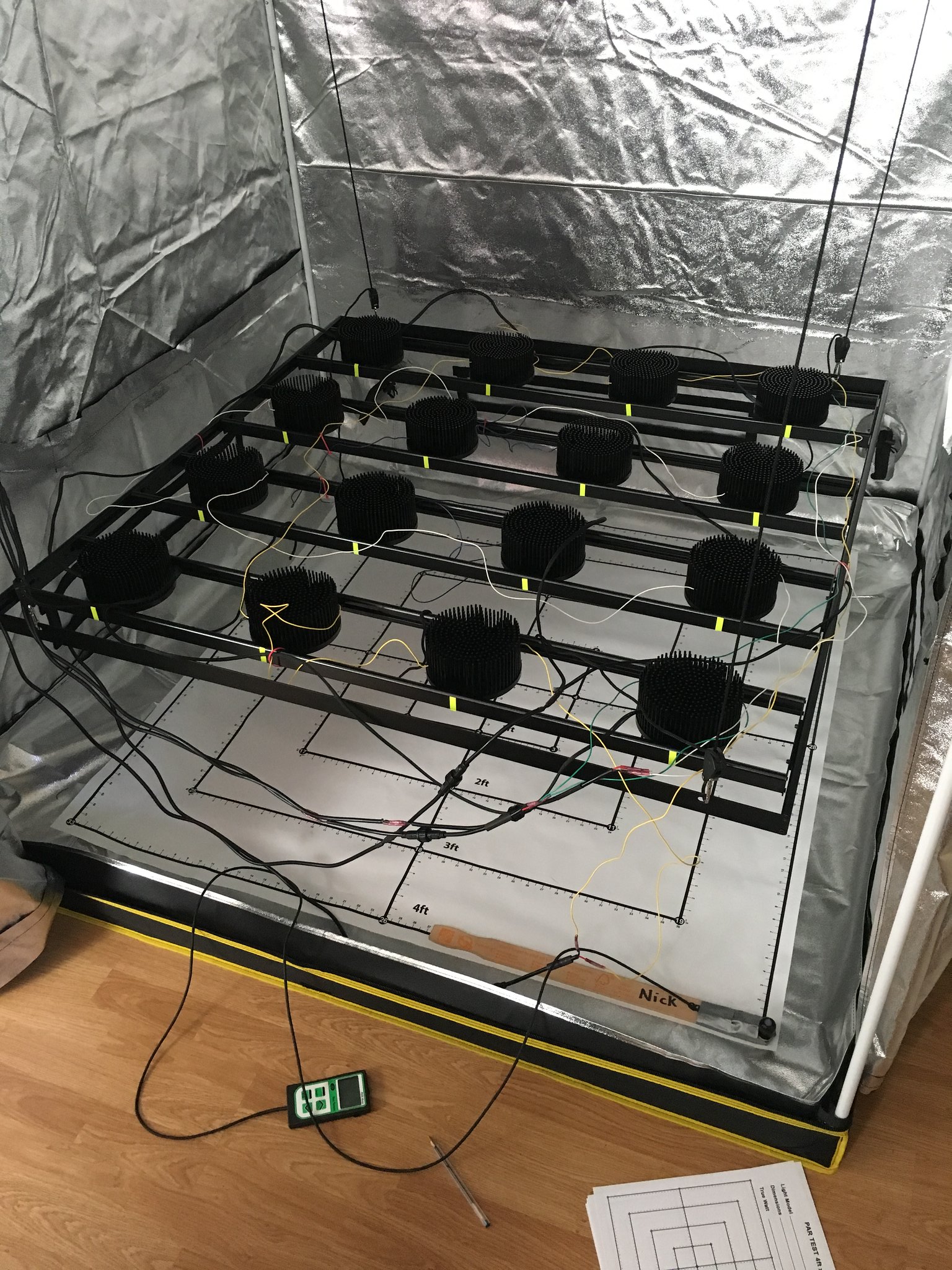

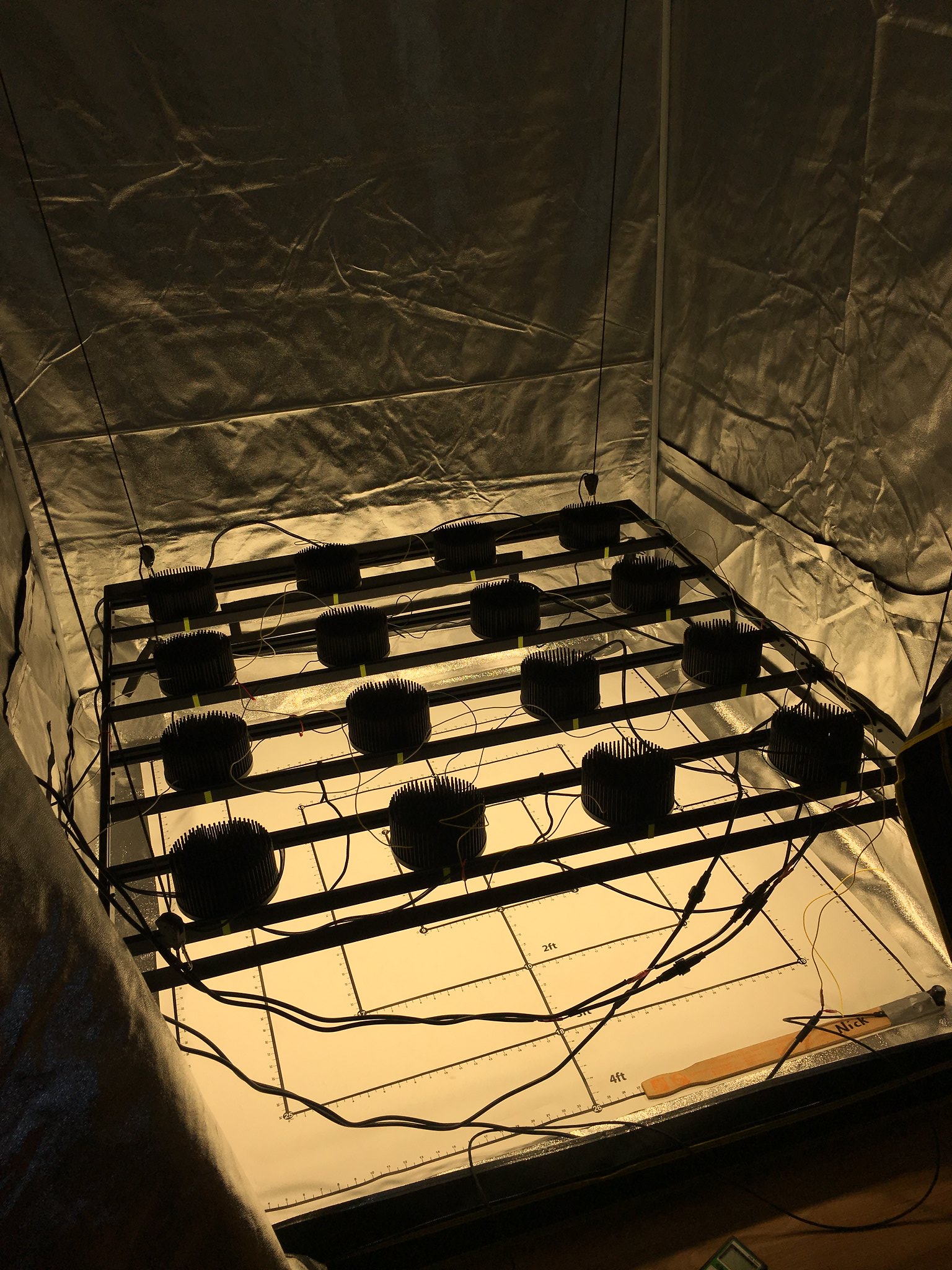

Set out to try and create a light with the most even PAR reading in a 4x4 ft space. This goal was set out after seeing how poorly most LED lights perform on the PAR chart. Some of the better LED lights do 1400-1600 in the middle but then drop to 150 at the corner of a 4x4. Since optimal growing par is between 1000-1200 (+/- Co2) and after testing some of the more popular lights on the market, I was left wondering a few things and set out to try to test it as best I could. Yes, after I take more par measurements I will be testing this. (Framework and tests conducted in a 5x5ft tent since the framework is 48in square it doesn't actually fit in a 4x4.)

Note: For the sake of keeping it simple, all questions are based upon a 4x4ft growing space/tent talking about flowering footprints.

1) Why do most LED light companies, with the exception of a few, build lights that do not reach the corners but advertise as a 4x4 flower space? If the plant is only getting 150 par in the corners, surely it will not grow as much or yield as much as if it was getting 600? Right?

2) Is it size related? Watt related, or both? Since spreading light to the corners is hard to do from a smaller 24in square light or even 30in square light, do most companies not worry about it because they dont want to build the lights 36-40in or because they know that it would make the light use much more power 30+% (My estimation) to get that extra PAR in the corners? Is this why most companies not show PAR readings?

3) Does it even matter or make a difference? Since part of the plant will be getting more light than the part facing the side of the tent, will the side closer to the light make up for the other side? Is the difference in yield between 150 par at 4ft corner and 600 par at 4ft corner so insignificant that the extra watts and overall light size to make it happen do not outweigh the benefits?

There has to be a reason for all of this? Would love to hear your theories.

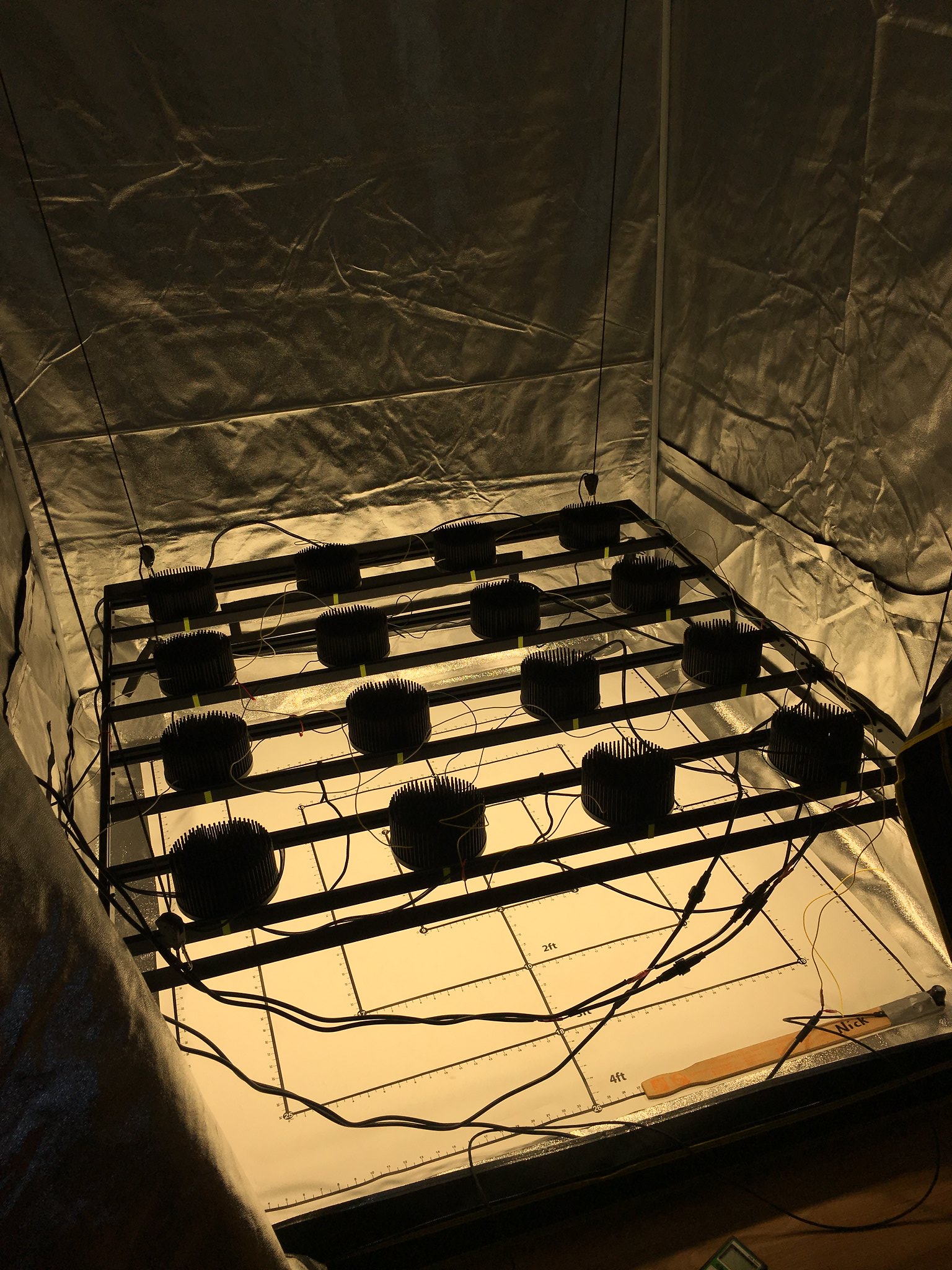

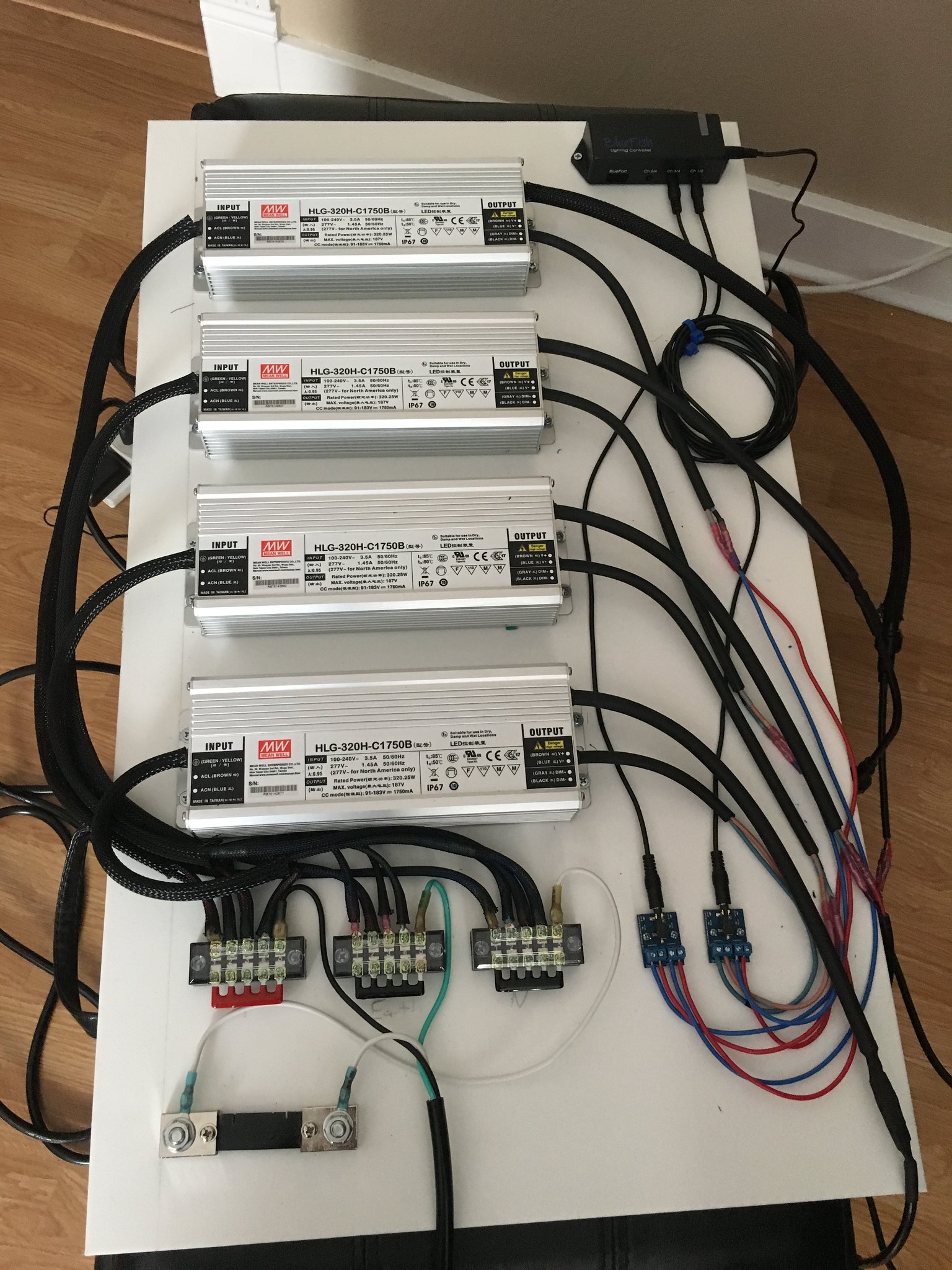

Below are pics of testing and the light that I have built to do so.

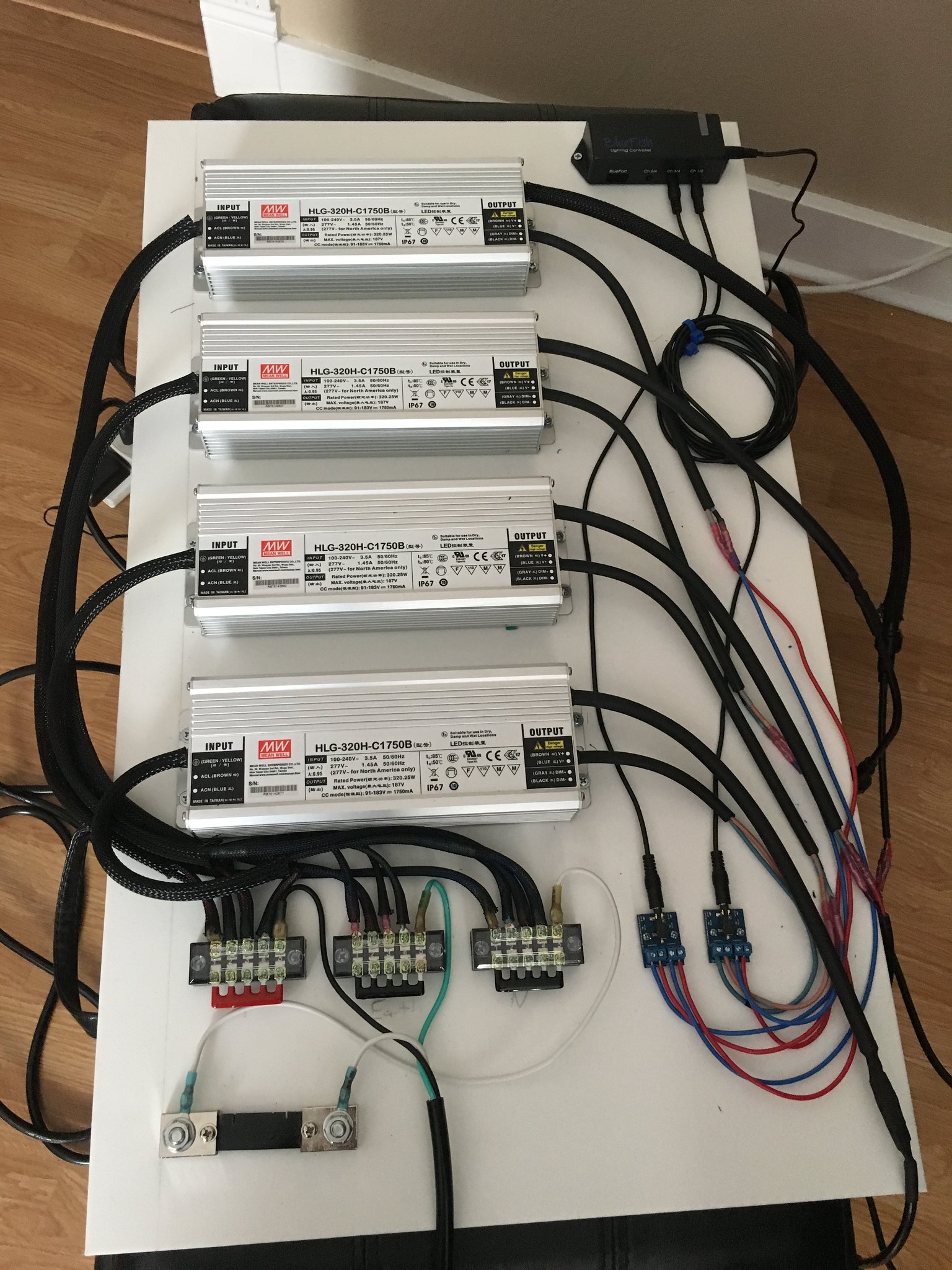

16Vero29 poke in cobs

16 140mm heat-syncs

4 MeanWell drivers HLG320H 1750Ma (Dimable)

Bluefish WiFi dimming controller

Sorry for the mess of wires, I wanted to be able to move things around and using soild wire is a PIA to do that with. Also, got about halfway wired all neat and tidy and thought i probably shouldent wrap the wires until I tested everything, I'll do that before an actual grow.

PAR readings at 18in with 4 drivers at 100% 1117 Watts

Par Readings at 18in with center 4 cobs running 60% the others at 100% 1005Watts

Would love to hear some thoughts comments and maybe insight in case i am missing the obvious to the questions asked.

Cheers

Justin

Really glad I found this forum. Have been watching lots of DIY videos from the likes of growmau5 and ChilLED and have inspired me to make my own. Pretty much all parts are from RapidLED, thanks for your guys help!

I am still pretty new to the LED community so please feel free to comment/askQ/answer Q's and tell me im full of it.

Set out to try and create a light with the most even PAR reading in a 4x4 ft space. This goal was set out after seeing how poorly most LED lights perform on the PAR chart. Some of the better LED lights do 1400-1600 in the middle but then drop to 150 at the corner of a 4x4. Since optimal growing par is between 1000-1200 (+/- Co2) and after testing some of the more popular lights on the market, I was left wondering a few things and set out to try to test it as best I could. Yes, after I take more par measurements I will be testing this. (Framework and tests conducted in a 5x5ft tent since the framework is 48in square it doesn't actually fit in a 4x4.)

Note: For the sake of keeping it simple, all questions are based upon a 4x4ft growing space/tent talking about flowering footprints.

1) Why do most LED light companies, with the exception of a few, build lights that do not reach the corners but advertise as a 4x4 flower space? If the plant is only getting 150 par in the corners, surely it will not grow as much or yield as much as if it was getting 600? Right?

2) Is it size related? Watt related, or both? Since spreading light to the corners is hard to do from a smaller 24in square light or even 30in square light, do most companies not worry about it because they dont want to build the lights 36-40in or because they know that it would make the light use much more power 30+% (My estimation) to get that extra PAR in the corners? Is this why most companies not show PAR readings?

3) Does it even matter or make a difference? Since part of the plant will be getting more light than the part facing the side of the tent, will the side closer to the light make up for the other side? Is the difference in yield between 150 par at 4ft corner and 600 par at 4ft corner so insignificant that the extra watts and overall light size to make it happen do not outweigh the benefits?

There has to be a reason for all of this? Would love to hear your theories.

Below are pics of testing and the light that I have built to do so.

16Vero29 poke in cobs

16 140mm heat-syncs

4 MeanWell drivers HLG320H 1750Ma (Dimable)

Bluefish WiFi dimming controller

Sorry for the mess of wires, I wanted to be able to move things around and using soild wire is a PIA to do that with. Also, got about halfway wired all neat and tidy and thought i probably shouldent wrap the wires until I tested everything, I'll do that before an actual grow.

PAR readings at 18in with 4 drivers at 100% 1117 Watts

Par Readings at 18in with center 4 cobs running 60% the others at 100% 1005Watts

Would love to hear some thoughts comments and maybe insight in case i am missing the obvious to the questions asked.

Cheers

Justin