(and no, I am not hostile towards Cobkits in last post, it is just a bun fight over how many cobs is enough - the answer is obviously there is never enough)

no offense taken, good discussion

i disagree with your premise tho

there is a such thing as diminishing returns and time value of money.lets say a big rig with 100 cobs at 75W. $10/cob

i can justify doubling the number of cobs to go from 75W/cob to 37W/cob to gain 18% in efficacy (+$750)

i can maybe justify going with 4x as many cobs to go from 75W/cob to 19W/cob to gain almost 30% in efficacy (+$2250)

doubing that already high cost to go 8x as many chips only gets you to 39% more efficient (+$5250)

lets double that again. 16x as many cobs and we are a full 53% more efficient than our original rig at 75W for a cost of +$11250

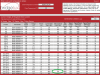

heres an ananysis of that **which doesnt take into account space limitations/time of drilling/tapping/mounting, or heatsink costs

starting with a baseline of 1.4 GPW youd see that the resulting product value (at $1500/unit) covers the cost of teh cobs in every case

*but* since wattage is static you would need to grow 18% more area in the first case, 30% in second case, and your garden square footage would be over 50% larger in the 3rd case. for the first step from 75 to 38W, we are investing $750 more in chips and getting a 8X return on that

for the largest array at 4.75W, we are investing $11250 and getting 1.63x of that amount back at harvest

most people dont have unlimited space to grow.

at this point youre like "aha cobby, i got you! you just demonstrated that you can keep adding cobs and they pay for themselves in just one grow!!!! Sure... but is that the best solution?

lets go another route. lets just increase the size of our garden by using one of the combinations above by running chips harder to cover more area. At 75W per chip i cant really go 153% of this as im out of the chip spec. let look at 30%. thats running chips at 97.5W

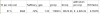

addl chip cost = 0

addl driver cost = $562 @ 0.25/W

chip efficiency at 97.5W = 12% less than 75W = 1.23 gpw

total watts =9750W (vs 7500)

metrics look like this:

yes that is less than the supplementary yields above BUT look at your ROI. spending just $562 yields you almost 9X the return. electric bill will pay you back as well, but this also takes time . so many factors that make you consider the time value of money:

-will you produce the crops you plan to or fall short?

-will the crops be worth the same value in the future as they are now?

what else can go wrong? you get sick and cant work? you lose crops to mold or bugs? youre in the wrong area and get popped?

laying out money now for future gains is ALWAYS a risk. and if youre not the average RIU users bangin 10's with your giant dick upon the stacks of money you have laying arount, it usually costs you money down the line to cough up capital now.

long story short, there are advantages to being more efficient but the LAW of diminishing returns assures that the moe you spend/more risk you take, the more incremental the upside becomes.

i like to think of it this way. somebody asked someone:

I'm curious, do you have an Engineering degree?

i might.... and what i might have learned is when you see a graph of yield vs cost and it has an elbow, the dogleg is where you want to be, because once it goes asymptotic, that is the very definition of diminishing returns. and thats industry agnostic, its fundamental. here is a chemical reaction (conversion vs time) that im all to familiar with from dayjobbin'

that 80-90% conversion you can get in 30 min is often more valuable than the 85-95 at 4x the time - you are losing throughput. "working the dogleg" is fundamental to cost analyses - its why we make those graphs in the first place. while its not as pronounced, our graph has a dogleg too. if i plotted cost vs efficacy it would be even more pronounced