My BML must be actively cooled by unicorn farts, because the heat sinks are running 88F at the edges, 92F at the center of the bar. Readings taken with a harbor freight laser thermometer. I know it can be dicey taking readings from reflective surfaces in this manner, so if anyone has a suggestion on measuring temps of heat sinks, I'd be happy to remeasure and post a picture.[/QUOTE]

Grow,

![201142217859501[1].jpg](/data/attachments/2532/2532829-11a313e387f0b9234dd96359dbb18bb8.jpg)

From Cree:

"LEDs produce light when a current is passed across the junction of the chip. As efficient as LEDs currently are, a large percentage of the input power generates

heat rather than light. Heat that is not dissipated will have not only an immediate negative impact on light output but also decrease the LED’s light output over time and could cause premature catastrophic failure."

"The Tj of an LED cannot be measured directly; it must be calculated using Equation 1 below, based on the measured Tsp, the total power input to the LED and the thermal resistance of the LED as stated on its data sheet."

Equation 1: Junction temperature calculation

Tj = Tsp + θth Ptotal

where:

Tj Junction temperature in degrees Celsius (°C)

Tsp Measured solder‑point temperature (°C)

θth Thermal resistance of the LED in degrees Celsius per watt (°C/W)

Note: thermal resistance can be found in the LED’s data sheet.

Ptotal Total power input to the LED (W)

Ptotal is calculated by multiplying the input current (If) by the forward voltage (Vf)

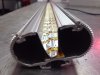

The design of the BML extrusion leads me to trust your temperature measurements, although my measurements were 20% greater across the length of the extrusion, and 2x on the 'screw'. For the discussion, I removed the "plastic" end cap from BML600 light bar. Notice where the LEDs reside and where the actual heat sinks are located.

Now look at how traditional heat sinks are designed:

![1024px-Pin_fin,_straight_fin_and_flared_heat_sinks[1].png](/data/attachments/2532/2532837-7760e374ca4a6551cca114797be32a08.jpg)

The 'heat source' resides on the opposite end of the actual heat sink fin or pin which increases higher thermal conductivity and efficiency.

Now going back to Cree's statement on the importance around proper thermal management design:

"As efficient as LEDs currently are, a large percentage of the input power generates

heat rather than light. Heat that is not dissipated will have not only an immediate negative impact on light output but also decrease the LED’s light output over time and could cause premature catastrophic failure."

When it comes to LEDs.........it is not cool to be cool!

![201142217859501[1].jpg](/data/attachments/2532/2532829-11a313e387f0b9234dd96359dbb18bb8.jpg)

![1024px-Pin_fin,_straight_fin_and_flared_heat_sinks[1].png](/data/attachments/2532/2532837-7760e374ca4a6551cca114797be32a08.jpg)