ChiefRunningPhist

Well-Known Member

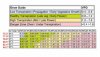

Nice colors!View attachment 4312181 View attachment 4312182 View attachment 4312183 View attachment 4312184 View attachment 4312185 View attachment 4312186 View attachment 4312187 View attachment 4312188 View attachment 4312189 Stick to vpd for led. Altho I'm running lower temps than suggested 84 but also get lucky when my rH gets above 45% in flower

Looks like you got her dialed! You must be under 79f or higher than 45% RH.

VPD "Danger Zone" for 40% RH starts @ 75°f.

VPD "Danger Zone" for 45% RH starts @ 79°f.

Last edited: