You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

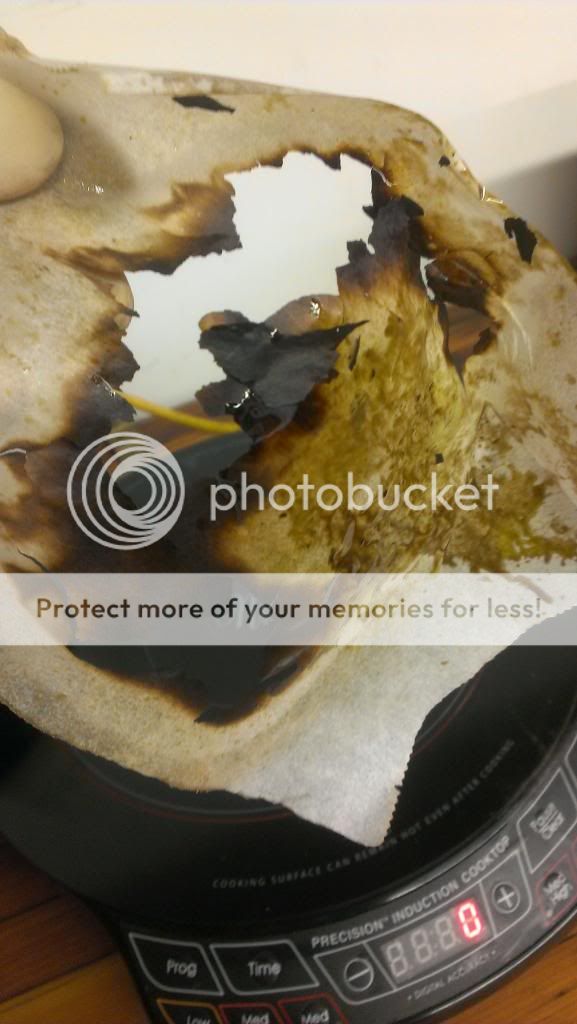

What went WRONG??

- Thread starter brownEs

- Start date

justugh

Well-Known Member

the paper

now adays the paper we are getting is a much thiner low grade mass produced recycled thing

u need to order a oil slick pad/mat

[video=youtube;D-vpP-0Ivbw]http://www.youtube.com/watch?v=D-vpP-0Ivbw[/video]

http://aqualabtechnologies.com/concentrate-utensils/oil-slick.html

now adays the paper we are getting is a much thiner low grade mass produced recycled thing

u need to order a oil slick pad/mat

[video=youtube;D-vpP-0Ivbw]http://www.youtube.com/watch?v=D-vpP-0Ivbw[/video]

http://aqualabtechnologies.com/concentrate-utensils/oil-slick.html

SaybianTv

Active Member

maybe your infrared was reflecting off the surface and reading a surrounding surfaces temps? happens all the time to me with glass and has Sapped many a batch. Sorry your paper went up in flames, i lost my marbles with parchment when it ripped during a sample session with some sap. Ask a woman who looks like she's got hands where you can buy some silicone cookie sheet's because your ugh cookies burnt last time. Don't buy oil slick pads, any food equipment shop with baking supplies will have it. That guy in the video shouldn't be blasting onto silicone, even oil slick manufacturer says the solvent will munch the pad.

Fadedawg

Well-Known Member

the parchment paper burned up while i was vac'ing( first time vac-ing btw) i set my induction cooker to 120* it was only in there for about 2 minutes then up in smoke it went! WTF

i was using 15 grams of trim.(what a waste)

Induction heating heats, using high frequency alternating current in a coil of wire, producing a rapidly alternating magnetic field.

The atoms placed in that field will try to align themselves magnetically with the fields polarity, and the fields rapidly changing polarity thus causes the atoms to oscillate rapidly trying to keep up.

This rapid oscillation, creates heat. Enough heat, that it is the preferred method in investment casting foundries to melt metal, including most non ferrous exotic alloys. Titanium and Zirconium being an exception, due to their highly exothermic reaction with ceramic crucible materials, when in a molten state.

Soooooo, I would say that there was something in the paper, or solution that was polar enough to be affected by the magnetic field. You can confirm whether it was the paper, or something on the paper that was heating up, by putting just some paper in the magnetic field and see what happens.

Did you scrape the oil off of a metal surface, using a metal blade? That could possibly put fine metal particles in your solution, which would heat up.

Fines would be affected more than a metal pot, which is what the system is probably calibrated for. The induction heating coils on the ones we used to melt metal, are all water cooled to keep them from melting in the field as well, so the units power has to be lower than their heat capabilities.

Fadedawg

Well-Known Member

That guy in the video shouldn't be blasting onto silicone, even oil slick manufacturer says the solvent will munch the pad.

Hi Greywolf,

I am sure you know, silicone swells in the presence on non-polar solvents. Hexane is actually used as a “swelling agent” for silicone tubing to allow for an easier connection. The swelling effect is the primary reason why silicone makes a poor compatibility choice when selecting a material to come into prolonged direct contact with non-polars.

As you must also be aware, chemical contamination from “extractables” in silicone materials, (in a procedure such as you are describing) is due almost entirely to the physical release of low molecular weight siloxanes, and other impurities from the manufacturing process. This is why Tygon 3350, or SaniTech-Ultra, are made with platinum cured silicone rather than the more common peroxide cured variety. This is also why We use platinum catalyzed USP6 silicone in our pads. (rather than peroxide/food grade).

As far as I am aware, we are the ONLY company doing this. The cost of material for a simple “baking mat” would be prohibitive in that industry.

For the record (sometime I feel like abroken record)We do not sell the Pad to spray directly onto. Many (many) folks do, and when we realized it (july of 2012), we switched the silicone we use as our raw material as aprophylactic measure.

We also removed the Logo from our pads, because we feared that immersion in non-polar solvent could act to weaken the bond between that thin layer of logo silicone, and the pad beneath. As concerned as we were about the logo....i cringe when I see folks spraying into parchment. The matrix of silicone in common parchment paper (non-Quilon / silicone coated) is extremely fragile compared to a pad. I imagine the violence of swelling and shrinking on that scale would be tenfold compared to the effect that prompted our own change of material.

The physical wear of swelling/shrinking/swelling/shrinking along with the various stresses inflicted by the innovative public (razor blades, torches etc...) make any sort of performance warranty unmanageable.

So we make em as pure as it gets, and when people ask us....we tell em that if they insist on using them this way, to please discard them if they notice any physical degradation.

I would refrain from cutting the pad to perform your testing, as this will expose the inner weave. Once cut or torn, the physical consequences of swelling could lead to damage along the exposed area.

Let me know where to send it, and I will get a Pad out to you today. Always happy to hear your thoughts. I redacted about 2 pages of hyper technical diatribe from this email.... because I figured you have likely done your own research regarding Pt cured silicone, and the various plasticizers that are used in food grade silicone. This is understandably a topic quite close to my heart; and I will be vary happy to discuss at length should you have specific questions (or non-specific musings?).

Also, should you require it, you have my explicit permission to share anything we discuss with whichever forums you are involved in.

Regards,

Joshua

Fadedawg

Well-Known Member

I did some testing, by weighing a Silicone rubber pad before soaking it in butane and weighing the weight gain, afterwards on a .0001 gram scale, and do solemnly swear that the Oil Slick manufacturer speaks the truth.

The above is the official gospel from the mountain, from the mouth of the prophet, with my own personal encouragement to believe and heed it:

The above is the official gospel from the mountain, from the mouth of the prophet, with my own personal encouragement to believe and heed it:

SaybianTv

Active Member

I read that article by them too, I don't think the majority of what's in canada is of the newer generation of pads and the pad game is dicey because human's are naturally cheap when it comes to when to throw something away. I evap ethanol in my pads by forming them into a bowl but that's post winterize very lil non polar left. I don't like scraping but i don't want to vape micro siloxanes so i purge my non polar on glass then wash it back into a soup with ethanol then purge again on regular comercial baking sheet's with the ethanol to render my final shape. These things are just too handy to ignore but reading the fine print helps you know when and when not to use them.

brownEs

Member

Can you describe your setup more? Induction heating isn't as simple as most standard methods.

I think the stainless steel pot I'm using was the problem. Its not magnetic. I tested by, setting my indthermometeroker to 100 degrees, it set the pot on it and watched the temperature with a infered thermometer. I went form room temp to 350* like in 5 seconds ,It was still climbing when I pulled it off.

Now I use a steel pan on cooker and the SS vacuum pot on top of that and the temperature stays where I was it.

BluJayz

Well-Known Member

Hi Greywolf,

I am sure you know, silicone swells in the presence on non-polar solvents. Hexane is actually used as a “swelling agent” for silicone tubing to allow for an easier connection. The swelling effect is the primary reason why silicone makes a poor compatibility choice when selecting a material to come into prolonged direct contact with non-polars.

As you must also be aware, chemical contamination from “extractables” in silicone materials, (in a procedure such as you are describing) is due almost entirely to the physical release of low molecular weight siloxanes, and other impurities from the manufacturing process. This is why Tygon 3350, or SaniTech-Ultra, are made with platinum cured silicone rather than the more common peroxide cured variety. This is also why We use platinum catalyzed USP6 silicone in our pads. (rather than peroxide/food grade).

As far as I am aware, we are the ONLY company doing this. The cost of material for a simple “baking mat” would be prohibitive in that industry.

For the record (sometime I feel like abroken record)We do not sell the Pad to spray directly onto. Many (many) folks do, and when we realized it (july of 2012), we switched the silicone we use as our raw material as aprophylactic measure.

We also removed the Logo from our pads, because we feared that immersion in non-polar solvent could act to weaken the bond between that thin layer of logo silicone, and the pad beneath. As concerned as we were about the logo....i cringe when I see folks spraying into parchment. The matrix of silicone in common parchment paper (non-Quilon / silicone coated) is extremely fragile compared to a pad. I imagine the violence of swelling and shrinking on that scale would be tenfold compared to the effect that prompted our own change of material.

The physical wear of swelling/shrinking/swelling/shrinking along with the various stresses inflicted by the innovative public (razor blades, torches etc...) make any sort of performance warranty unmanageable.

So we make em as pure as it gets, and when people ask us....we tell em that if they insist on using them this way, to please discard them if they notice any physical degradation.

I would refrain from cutting the pad to perform your testing, as this will expose the inner weave. Once cut or torn, the physical consequences of swelling could lead to damage along the exposed area.

Let me know where to send it, and I will get a Pad out to you today. Always happy to hear your thoughts. I redacted about 2 pages of hyper technical diatribe from this email.... because I figured you have likely done your own research regarding Pt cured silicone, and the various plasticizers that are used in food grade silicone. This is understandably a topic quite close to my heart; and I will be vary happy to discuss at length should you have specific questions (or non-specific musings?).

Also, should you require it, you have my explicit permission to share anything we discuss with whichever forums you are involved in.

Regards,

Joshua

Great read, so if i'm getting this right (at 6am) the new slick pads are able to "handle" direct non-polar and polar prolonged exposure?

It's frowned upon but they've increased the technology behind it?

That would make me a little more comfortable using them in general.

qwizoking

Well-Known Member

As concerned as we were about the logo....I cringe when I see folks spraying into parchment. The matrix of silicone in common parchment paper (non-Quilon/ silicone coated)is extremely fragile compared to a pad. I imagine the violence of swelling and shrinking on that scale would be tenfold compared to the effect that prompted our own change of material.

So we make em as pure as it gets,

I don't know man..I was under the impression it was because silicone is wonderfully soluble in hexane.......also baking parchment isn't made with silicone....

http://www.cemag.us/articles/2004/06/silicone-contamination-part-3#.UlbQe_xOnFo seems to support my ideas just a quick search idk.. as well as most articles talking about the swelling also talk about tear strength, compression, or color. Being altered from the use

So we make em as pure as it gets,

I don't know man..I was under the impression it was because silicone is wonderfully soluble in hexane.......also baking parchment isn't made with silicone....

http://www.cemag.us/articles/2004/06/silicone-contamination-part-3#.UlbQe_xOnFo seems to support my ideas just a quick search idk.. as well as most articles talking about the swelling also talk about tear strength, compression, or color. Being altered from the use

Similar threads

- Replies

- 1

- Views

- 687

- Replies

- 41

- Views

- 5K

- Replies

- 4

- Views

- 815

- Replies

- 18

- Views

- 4K