CobKits

Well-Known Member

so lets be all caveman and take a 1/4" piece of solid aluminum bar which should be cheaper than a heatsink

if you had a 1 square foot piece of this, is it safe to assume that you radiate heat from top and bottom and so you count 2 square feet of surface area (negating edge thickness)

1 sq ft = 930 cm^2

2 sq ft = 1860 cm^2

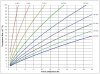

used passively thats 1860/120 = 15.5 heat watts that can be dissipated

with fans blowing on both sides thats 1860/40 = 46.5 W

amirite? or do we only count the top (im thinking passive... on a large sheet where the heat could get 'trapped' underneath)

if you had a 1 square foot piece of this, is it safe to assume that you radiate heat from top and bottom and so you count 2 square feet of surface area (negating edge thickness)

1 sq ft = 930 cm^2

2 sq ft = 1860 cm^2

used passively thats 1860/120 = 15.5 heat watts that can be dissipated

with fans blowing on both sides thats 1860/40 = 46.5 W

amirite? or do we only count the top (im thinking passive... on a large sheet where the heat could get 'trapped' underneath)