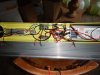

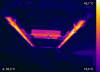

I think I'm better at building the enclosures... So finished up, turned on nothing blew up but its not very bright. Dimmer is working, unplugged that to see if it changed the wattage, no, only getting 57 watts. The leads from the driver show 140 volts dc, those were attached to the terminal strips, the 4 cobs are in parallel from those strips. When I check the voltage of the strips with the cobs on it shows about 25 volts. I disconnected the leads from the strips still 140 volts. Hopefully someone smarter than me could advise.

Attachments

-

3.1 MB Views: 95

-

3.3 MB Views: 90

-

3.1 MB Views: 89

-

3.3 MB Views: 88

-

3.2 MB Views: 90