How to determine the driver for your LED's in a 2x2?

- Thread starter kdt15

- Start date

Airwalker16

Well-Known Member

Time to watch Growmau5 COB DIY basics videos on YouTube. There's like 4-7 vids.with 30-40w/swft, total of 120 (maybe 100?) - 150W total in a 2x2. What i dont get is how to find out what driver is suitable for these needs. any ideas?

Sit down and spend the time watching those. You will answer yourself most of your questions.

But in short, Ohms Law.

Amperage(Milliamps) X Voltage = Watts.

Ex.

36watt COB X 1400MA or 1.4AMPS (HLG-185H-C1400B meanwell driver)=50watts.

The "185" part in the model number is a close number to the drivers maximum wattage. It will have a MINIMUM and Maximum Voltage Range being 80something to 144Volts. 36Volt COBs, 144/36=4. 4 COBs will fit on that driver.

Last edited:

thanks! is the 80-144V something written on the spec sheet that i will have to check each time, and i would have to math it out on my own by adding the V ratings from my strips together and making sure it doesnt exceed my driver?Time to watch Growmau5 COB DIY basics videos on YouTube. There's like 4-7 vids.

Sit down and spend the time watching those. You will answer yourself most of your questions.

But in short, Ohms Law.

Amperage(Milliamps) X Voltage = Watts.

Ex.

36watt COB X 1400MA or 1.4AMPS (HLG-185H-C1400B meanwell driver)=50watts.

The "185" part in the model number is a close number to the drivers maximum wattage. It will have a MINIMUM and Maximum Voltage Range being 80something to 144Volts. 36Volt COBs, 144/36=4. 4 COBs will fit on that driver.

the issue with your example is 4.4 cobs will fit there but a max of 144V * 1.4A = 201.6W which exceeds the '185' rating, does this mean this is NOT safe to go with and i should find a '200'+ driver?

~~~~~~~

what specs do i look at to determine a proper fit driver?

lets say for example we are following the 2x2 F series build for 1ft strips https://ledgardener.com/diy-led-strip-build-designs-samsung-bridgelux/

Code:

4x Samsung LT-F284B 1′ Strips ($37) Note- these strips may be hard to find in small quantities.

1x Mean Well HLG-120H-C1400B Driver ($45)so the build specs end up being 131W which is greater than 120W which is why im confused.System Specs:

Type: C.C./Series

Diode Count: 288

System Voltage: 93.9V

System Current: 1,400mA

System Power: 131.4W

Lumen Estimate (3000K): 21,981

Efficacy: 167 lm/w

furthermore, why not something like the other HLG ones mentioned in his other builds there?

the 700B i can guess is too low of an amp for this series build. However, im confused at the 24B once since im not sure what that even meansMean Well HLG-120H-C1400B Driver

Mean Well HLG-120H-24B Driver

Mean Well HLG-120H-C700B Driver

ChiefRunningPhist

Well-Known Member

Yepwhat does the 120H mean? (is it 120W?) and the 1400 I presume is 1.4A max

You'll want to shoot for ~30W per sq ft when using LED.

2ft × 2ft = 4ft2

(30W/ft2) × (4ft2) = 120W

Watts = Volts × Amps

LEDs flow a specific Current when a certain Voltage is applied, the more Voltage that's applied, the more Current the LED tries to flow. Current only flows if there's a Voltage present.

You've determined you need 120W for a 2'×2' space, but the exact Voltage & Current that are multiplied together to achieve the 120W is not known, yet.

You're going to have to find what the "Forward Voltage" (Vf) is of your LED fixtures. A "Forward Voltage" (Vf) rating is a ballpark measurement indicating the necessary Voltage needing to be supplied for the LEDs to operate at typical conditions.

For example, let's say you have a few strips with a "Vf" of 23V each. Great, now that you know that, the next thing you'd have to determine is the "Forward Current" when the strip has 23V applied. Sometimes they give these figures, but most times you'll have to look at the data sheet for the individual LEDs that populate the strip/board. It requires a bit if back calculating but it's not hard.

Let's say the strips consisted of (8 ) LM561C chips in series. This means that the 23V Forward Voltage is divided up into (8 )different chips.

23V ÷ 8 = 2.875V

So 2.875V per LED is realized when 23V is applied across the entire strip.

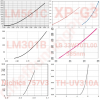

Looking at the data sheet for LM561C...

It looks like when 2.875V is applied to a LM561C, that it wants to flow close to ~120mA of current. This means the strip requires 23V total, or 2.875V/LED, to flow 120mA through all (8 ) series LEDs (LM561C's).

120mA = 0.120A, and since Volts × Amps = Watts, 23V × 0.120A = 2.76W strip.

2.76W is very small, and you can tell I was just making up a strip as I went (lol) but this is the way you'd essentially do it. You can determine "Forward Voltage" of a series wired strip by looking at the data sheet and finding the Voltage per the Current you want to run, then multiply the data sheet Forward Voltage (from graph) by the number of chips in series to get the Vf of the total strip (per your desired current).

Series wiring is single file, 1 after the other, Parallel wiring is side by side (pretty vague description lol look it up or check the link in my sig). You can have all series wiring, all parallel wiring, or some combo of both.

If you ran 10 of the 2.76W strips in parallel, then your driver would need to be capable of outputting 23V, and 1200mA, or 1.2A. In parallel wiring, Volts stay the same, but Current gets divided by how many strips are present, in our case 10, and if you knew you needed to be able to supply 120mA or 0.12A per strip and you wired 10 in parallel, then you'd need 1.2A total so that when the current was divided 10 ways that each strip still got the desired 120mA.

If you ran 10 of the 2.76W strips in series, you'd want a driver capable of outputting 230V, and 120mA, or 0.12A. In series wiring current stays the same, but total Voltage is divided by the number of strips. 10 strips wired in series, each needing 23V to flow 120mA, means your driver would need to be able to output 230V and 120mA, or 0.12A.

120H CC driver (5) different 120W drivers with different Voltage and Current Output characteristics ...

120H CV driver, (9) different 120W drivers with different Voltage and Current Output ranges...

**On ALL Mean Well drivers you can reduce current flow via a built in screw knob called a potentiometer, or POT for short (A models), or via a 110kΩ aftermarket POT attached to the dimmer leads (B models). It allows for tuning because not every driver will fit perfectly for every setup.

On this graphic you can see an example showing the differnce between series and parallel along with other electrical equations etc...

Last edited: