Mikov

Member

so i might have a very tight space to work with in the future, with not much space to vent out hot air. so instead i've decided i'll study up a bit and build my own ac unit or air chiller.

right now my knowledge on ACs is pretty lacking so this is an open request for any links to threads on here of people that have made a cooling system from scratch or something along those lines.

so this is an open request for any links to threads on here of people that have made a cooling system from scratch or something along those lines.

i know you're thinking it's a waste of time, and that i should just go buy one, but i invested all my money in my avatar. maybe i'll buy a cheapo at goodwill and take it apart and upgrade it or something.

i'm just compiling reading material right now, and as time goes on i'll absorb as much as i can and build one of the best design.

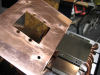

i thought it'd be cool to make something like this and i'll post pics of the process and finished product.

so please throw me any reading you have on keeping a temp low or how an ac works or how to build one. i don't want wiki links or something i'll be able to google mine in a couple seconds. so share with me something you think i wouldn't know, or couldn't find with a quick search.

i have a general idea in my head, and as i read up i'll sketch up some designs and post em here to get some constructive criticism.

heat is going to be my biggest problem so i'm going to be taking this kinda seriously.

fortunately it'll only be a couple lights, so it doesn't have to be super industrial.

so an optimal ac unit or chiller unit would be:

-cheap to make(i've got a carpentry background)

-easy on the ears, not loud.

-easy on the electricity, pulling barely any amperage.(for the sake of other stuff i'll have on the circuit)

-chill the room without being fed a cooling agent every day.

if there's any points i missed please fill me in. anyway give me your feedback, if it's cheaper and easier to buy, you'll have to convince me. besides i would love to build one just for the experience and knowledge.

and a bonus is all you guys that wanna tag along will learn a boat load, and the forum will have a nice guide to ACs.

here's my questions so that we can get this collaboration started:

so that we can get this collaboration started:

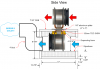

-i'm thinking a maze of walls that the air has to weave around, and these walls(made of copper pipes?) would be cold all the time because of a cooling agent running through them, and that would keep the air cool.

-would radiator fluid through some copper pipes do the trick?

-what's the cooling agent used in most ac units?

-is it possible to have a cooling unit without moving parts? a completely static cooler would be ideal because it'd be the easiest to make and maintain. unfortunately it seems like i'd need at least a pump for the fluid in the maze idea.

-what about a maze made out of thick concrete? would it keep the air cool effectively or would the stone just warm up after a couple hours and be useless?

~~~~~~~~~~~~~~~~~~

i'll find the answers to those one way or another and post my thoughts here. if you have some answers/questions/input i'm very open to suggestions.

link me to any useful threads!

right now my knowledge on ACs is pretty lacking

so this is an open request for any links to threads on here of people that have made a cooling system from scratch or something along those lines.

so this is an open request for any links to threads on here of people that have made a cooling system from scratch or something along those lines.i know you're thinking it's a waste of time, and that i should just go buy one, but i invested all my money in my avatar. maybe i'll buy a cheapo at goodwill and take it apart and upgrade it or something.

i'm just compiling reading material right now, and as time goes on i'll absorb as much as i can and build one of the best design.

i thought it'd be cool to make something like this and i'll post pics of the process and finished product.

so please throw me any reading you have on keeping a temp low or how an ac works or how to build one. i don't want wiki links or something i'll be able to google mine in a couple seconds. so share with me something you think i wouldn't know, or couldn't find with a quick search.

i have a general idea in my head, and as i read up i'll sketch up some designs and post em here to get some constructive criticism.

heat is going to be my biggest problem so i'm going to be taking this kinda seriously.

fortunately it'll only be a couple lights, so it doesn't have to be super industrial.

so an optimal ac unit or chiller unit would be:

-cheap to make(i've got a carpentry background)

-easy on the ears, not loud.

-easy on the electricity, pulling barely any amperage.(for the sake of other stuff i'll have on the circuit)

-chill the room without being fed a cooling agent every day.

if there's any points i missed please fill me in. anyway give me your feedback, if it's cheaper and easier to buy, you'll have to convince me. besides i would love to build one just for the experience and knowledge.

and a bonus is all you guys that wanna tag along will learn a boat load, and the forum will have a nice guide to ACs.

here's my questions

so that we can get this collaboration started:

so that we can get this collaboration started:-i'm thinking a maze of walls that the air has to weave around, and these walls(made of copper pipes?) would be cold all the time because of a cooling agent running through them, and that would keep the air cool.

-would radiator fluid through some copper pipes do the trick?

-what's the cooling agent used in most ac units?

-is it possible to have a cooling unit without moving parts? a completely static cooler would be ideal because it'd be the easiest to make and maintain. unfortunately it seems like i'd need at least a pump for the fluid in the maze idea.

-what about a maze made out of thick concrete? would it keep the air cool effectively or would the stone just warm up after a couple hours and be useless?

~~~~~~~~~~~~~~~~~~

i'll find the answers to those one way or another and post my thoughts here. if you have some answers/questions/input i'm very open to suggestions.

link me to any useful threads!