guod

Well-Known Member

next spectrum tool >>> BETA TEST

http://www.ledspecs.com/

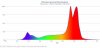

Flower-Spectrum of the new Light with it

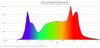

Veg Spectrum...

http://www.ledspecs.com/

Flower-Spectrum of the new Light with it

Veg Spectrum...

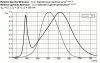

same here...-Guod ,I've some indications (just indications ,though...) ,that some yellow -amber light ( 580-620 nm ) is needed for flowering ...

I'll raise your 580-620 with a big dose of 630= the PS sweet spot for flowering mmj-Guod ,I've some indications (just indications ,though...) ,that some yellow -amber light ( 580-620 nm ) is needed for flowering ...

>

Maybe I'm wrong ....

But those wls ,have something to do with flowering ....

( I've been reading/studying a bit about yellow-amber wls , different species of insects and how they react to those wls and

the relation of all these with flowering plants ....Something is there ....I'm not sure yet .... )

from scratch.very clean cut project. quality work buddy. is this a kit you purchased or is this from scratch?

no clue!Guod ,a question .....

While Thin Film Tech leds for sure are way more efficient than Volume Emission Leds ,as

also they have really low R Th ( thermal resistance ) ......

But is it possible for Volume Emission dies-chips , to be more heat tolerant ,due to thicker materials used in die/chip construction* ?

*( Thicker semiconductor "sandwich " )

Know anything about it ?

our next Light will have the best of both worlds. cree XPG(2) for CW and WW, Osram for red, blue and WW.Love the LED threads on rollitup! After looking through some threads, most of the guys seem to be using Cree WW LEDs, especially XT-E, my question is, what's the way to go here, more efficient Cree emitters or better spectrum with the Oslons? Do you have experience with this? (esp. guod and SDS)

much more efficient Cree...Nice, waiting for your results!

...

Looks like you can ditch the Oslons altogether and use the much more efficient Cree counterpart!