yktind

Well-Known Member

Sorry Guys I made a mistake. We will not be brewing an IPA we will be brewing an Imperial IPA. What the hell is the difference. Well its just numbers really. Take a look:

This is out of How To Brew: J. Palmer

Indian Pale Ale Style Guidelines:

SubStyles -------- OG (Original Gravity) ------- Degrees Plato ------- FG (Final Gravity) -------- IBUS (International Bittering Units) --------- Color

English IPA -------------- 1.050 - 75 -------------------- 12.5 - 18 ----------------------- 1.010 - 18 ------------------------------ 40 - 60 ------------------------------ 8 -14

American IPA ----------- 1.056 - 75 -------------------- 13.5 - 18 ----------------------- 1.010 - 18 ------------------------------ 40 - 60+ ---------------------------- 6 -15

Imperial IPA ------------ 1.075 - 90+ ------------------- 18 - 22+ ----------------------- 1.012 - 18 ------------------------------ 60 - 100+ --------------------------- 8 -15

*Note*

I will do a write up on how to measure using a hydrometer soon. This is kind of jumping ahead in the book. But Why waste time we have to taste this soon to be delicious beer.

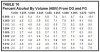

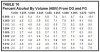

OG - FG Approximate ABV Chart:

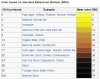

Plato Conversion Chart (This is usually used with a Refractometer. I do not have one therefore I won't be going into to detail):

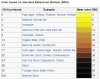

Color Rating Chart:

I need to do some more reading about yeast and making a starter then I will post the recipe and an explanation on yeast.

This is out of How To Brew: J. Palmer

Indian Pale Ale Style Guidelines:

SubStyles -------- OG (Original Gravity) ------- Degrees Plato ------- FG (Final Gravity) -------- IBUS (International Bittering Units) --------- Color

English IPA -------------- 1.050 - 75 -------------------- 12.5 - 18 ----------------------- 1.010 - 18 ------------------------------ 40 - 60 ------------------------------ 8 -14

American IPA ----------- 1.056 - 75 -------------------- 13.5 - 18 ----------------------- 1.010 - 18 ------------------------------ 40 - 60+ ---------------------------- 6 -15

Imperial IPA ------------ 1.075 - 90+ ------------------- 18 - 22+ ----------------------- 1.012 - 18 ------------------------------ 60 - 100+ --------------------------- 8 -15

*Note*

I will do a write up on how to measure using a hydrometer soon. This is kind of jumping ahead in the book. But Why waste time we have to taste this soon to be delicious beer.

OG - FG Approximate ABV Chart:

Plato Conversion Chart (This is usually used with a Refractometer. I do not have one therefore I won't be going into to detail):

Color Rating Chart:

I need to do some more reading about yeast and making a starter then I will post the recipe and an explanation on yeast.