So I walked away and educated myself a bit more and discovered that SupraSPL had uploaded a copy of his spreadsheet, and for a guy like me, that's the Holy Grail.

I made some modifications based on what I have learnt here and hopefully discovered all the answers I wanted, only to then find an error in SupraSPL's spreadsheet which impacted directly on my work.

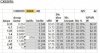

The snippet of the CXB2530 from the COB spreadsheet thread below which I posted previously in this thread is at this stage an unknown.

View attachment 3617064

Notice the underlined

CXB2530 above the spreadsheet is not the same as in the top row in the spreadsheet, which is CXB2350. I've put up a post in the COB spreadsheet thread regarding this discrepancy in order to clarify what the correct labelling should be. You can read my post here for a detailed explanation if you wish.

https://www.rollitup.org/t/cob-efficiency-spreadsheets.865238/page-18#post-12360078.

Needless to say, I am keen to find out exactly what COB it represents as will become apparent further down.

So with that in mind, I won't be sure what data is being represented in the samples below were references to CXB2530 are made until SupraSPL or someone else can clarify which COB the data really represents. Regardless I'll press on, as all the other information is correct, assuming my calculations are correct.

I modified the original spreadsheet and added the following information based on the formulas provided:

- Green area where cabinet dimensions added for later calculations.

- Red areas indicating the number of COBs to evaluate, as well as there Unit cost & Totals.

- Blue area:

- PAR(W)/COB = 50c dissW * 50c %

- PAR (W) Total = PAR(W)/COB * # COBS

- PPF = PAR (W) Total * 4.51

- PPFD = PPF * Area (Metres²)

- W/Feet² = ((# COBS * 50C %) / Area (Feet²)) * 100

The first thing that became apparent was the area I had to work with. In my first post I noted the chamber size as

860mm wide x 450mm deep and it's 1200mm high (approximately 3.5' x 1.8' & 4' high). My mistake was using "round about" figures for the dimensions in feet, and as such all further calculations were based on those figures equalling about 6 feet². Well, a proper conversion shows that I actually have 4.165668 feet².

Anyway, this is what I have found.

If I give myself a budget of around $150 for COBS this is what I get:

View attachment 3617109

If I give myself a budget of around $200 for COBS this is what I get:

View attachment 3617110

I haven't costed a driver into the equation, but my budget for COBS & Driver is around $300, so with the 2 spreadsheets above I've allowed enough room to get close or slightly above my $300 limit.

Excluding the CXB2530 figures for now as I'm not sure what the data represents yet, and assuming my formulas are correct, then the 3 * CXB3590 @ 0.7A & 4 * CXB3070 @ 0.35A are getting close to the magic 50W/foot² figure based on the new area of 4.165668 feet² if I spend $200 on COBS. The figures for the CXB2530 look absolutely brilliant, and based on the price would definitely be the way to go, but I'm kind of stuck until I know what COBs that data represents.

Does all this look about right?

Thanks.