Mau5Capades: builds & grow journal

- Thread starter Growmau5

- Start date

robincnn

Well-Known Member

You need to slow down you making everyone feel bad....

This looks like one of the cleanest, meanest,most efficient Absolute PRO DIY. I see you used A type HLG for built in pots.

Thanks for the new ideas. You already tried ledil reflectors. I will wait for your opinion of these lenses.

Is it 5.886" wide 36inch long Heatsink USA profile. With 36 heat watts that heatsink must be close to room temperature.

Since you have the cob in sealed environment. If possible please visually check LES and let us know about VOC discoloration on LES after 100hrs and 1000hrs of operation.

I would like to know about the connectors you used on the junction box.

Is the blue connector this one?

What is the red connector ?

This looks like one of the cleanest, meanest,most efficient Absolute PRO DIY. I see you used A type HLG for built in pots.

Thanks for the new ideas. You already tried ledil reflectors. I will wait for your opinion of these lenses.

Is it 5.886" wide 36inch long Heatsink USA profile. With 36 heat watts that heatsink must be close to room temperature.

Since you have the cob in sealed environment. If possible please visually check LES and let us know about VOC discoloration on LES after 100hrs and 1000hrs of operation.

I would like to know about the connectors you used on the junction box.

Is the blue connector this one?

What is the red connector ?

Last edited:

Growmau5

Well-Known Member

@robincnn I will check for discoloration of the LES. Thanks for the kind words.

The connectors circled in red are called:

PG9 Black Waterproof Cable Gland Connectors

Blue is:

Generic 5.5mmx2.1mm DC Power Supply Adapter Metal Jack Socket

and yeah, those 5.886 profiles are room temp all around, even on the edges.

The lower blue circled connectors are indeed the ones you linked, but I have discovered that the male ones work just great, but the female ones suck and about 25% of them have poor contacts.

The connectors circled in red are called:

PG9 Black Waterproof Cable Gland Connectors

Blue is:

Generic 5.5mmx2.1mm DC Power Supply Adapter Metal Jack Socket

and yeah, those 5.886 profiles are room temp all around, even on the edges.

The lower blue circled connectors are indeed the ones you linked, but I have discovered that the male ones work just great, but the female ones suck and about 25% of them have poor contacts.

Last edited:

BillyBudThornton

Well-Known Member

LEDivas...that's what you all is!

salmonetin

Well-Known Member

...i like a lot your diy  ......but...just my pov...

......but...just my pov...

...i saw waterproofed connectors mixed with non-waterproof connectors... for my pov its a bit nonsense... better go on full waterproofed way for junction box/es...

...i dont like too much the generic power suply adapters for dc drivers side connectors... and you comfirm my pov ...you said ...

...but the female ones suck and about 25% of them have poor contacts...

...poor contacts on dc driver side... its a near or future problems for my pov... why not other waterproofed connectors with better contact here too?...

...on principal ac wire cable for junction box...i will use only the external connector for connect ac wire to wall...and in the other side the wire go inside the junction box ...i prefer internal (waterproofed) connections on ac side...no need other external connector... just internal connectors... with wago or similar screwless type...and some system to seal the wire and box from water too...

...on passive way on drivers i dont like to put nothing over the drivers...i put the junction box beside of drivers not over the drivers...better on passive way...for long runs...

...and Every Part shall be Easy Accessible for Full Inspection, Testing and Maintenance or Substitution proposites on our diy lamps...

...https://www.rollitup.org/t/diy-led-grow.738671/page-47#post-11949601...

...i know Wilson... but i prefer help on diy side than the commercial side... and yeah maybe a bit offtopic ...and maybe GM dont like it... then...

e function desactived...thanks GM..

pd...for my pov its not criticism.... its just other pov...

...on wires i prefer sustitute the entire cable than add one extension... maybe just my old profesional formation....but sometimes i use extension on wires but only on temporal way ....again just my opinion or pov...

pd1...Ill used them next time::... lol...tipycal phrase from mans to women...

....women tipical answer... promises ...promises... ...just jokin..

...just jokin..

Saludos

......but...just my pov...

......but...just my pov......i saw waterproofed connectors mixed with non-waterproof connectors... for my pov its a bit nonsense... better go on full waterproofed way for junction box/es...

...i dont like too much the generic power suply adapters for dc drivers side connectors... and you comfirm my pov ...you said ...

...but the female ones suck and about 25% of them have poor contacts...

...poor contacts on dc driver side... its a near or future problems for my pov... why not other waterproofed connectors with better contact here too?...

...on principal ac wire cable for junction box...i will use only the external connector for connect ac wire to wall...and in the other side the wire go inside the junction box ...i prefer internal (waterproofed) connections on ac side...no need other external connector... just internal connectors... with wago or similar screwless type...and some system to seal the wire and box from water too...

...on passive way on drivers i dont like to put nothing over the drivers...i put the junction box beside of drivers not over the drivers...better on passive way...for long runs...

...and Every Part shall be Easy Accessible for Full Inspection, Testing and Maintenance or Substitution proposites on our diy lamps...

...https://www.rollitup.org/t/diy-led-grow.738671/page-47#post-11949601...

...i know Wilson... but i prefer help on diy side than the commercial side... and yeah maybe a bit offtopic ...and maybe GM dont like it... then...

e function desactived...thanks GM..

pd...for my pov its not criticism.... its just other pov...

...please dont saw it on criticism way... its just other pov way... i respect all ways on diy...@salmonetin I appreciate the comments and constructive criticism.

...for my pov... i prefer waterproofed junction box...with external waterproofed connectors or wires too...just my opinion... ...my waterproof pov are not in the ip or ul listing for selling too... just about our security reasons...for persons and for our electrical hardwares... ...my choice is bassed on what i need and what i can buy here...@salmonetinFirstly, my priorities are safety and cleanliness, I could care less about waterproofing, IP or UL listing and I am not trying to sell these lights. My choice in connectors is based on cool shit I find on amazon.

...i know lot of commercial lamp enclose these drivers ....i just show you my preferences or pov about drivers on passive way... nothing over the heatsink or drive for better natural ventilation...off course... you can enclose your drivers... but its not my prefered way on passive way...again just my pov...@salmonetinCompanies enclose these meanwell drivers inside of hot metal fixtures all the time. My little junction box sitting with a 1/2" air gap in front of the drivers isnt going to do jack to the temperature or longterm function and reliablility of the drivers.. I don't know wtf ur talking about here... additionally, the drivers include about a foot of wire to work with, without having to solder an extension. thats why I did it this way. Thats one less connection point per driver (x4)

I was referring to these ones , which do suck.

View attachment 3518288

The metal ones I used are just fine. I did some stress testing to them, jiggling them around and such. The connections are solid. But I agree, these would be better... Ill used them next time::

View attachment 3518290

...on wires i prefer sustitute the entire cable than add one extension... maybe just my old profesional formation....but sometimes i use extension on wires but only on temporal way ....again just my opinion or pov...

....again i respect your election or general elections on ballast... if work for you why not?...but again i show you my pov...i prefer dont use it on humidity ambients...no matter what other says or use...its my preference maybe too influenced for my old electrical formation... ...from my pov... with removable power cord ..you add one extra connector to the system than my idea...(no removable cord... only need a fixed cord to the junction box)...then....we have a removable junction box from my pov...@salmonetinOn the AC side, I like removable power cords, the same ones used in hundreds of thousands of HPS ballasts hanging in grow rooms across the world. If its good enough for all of them, its good enough for me...

pd1...Ill used them next time::... lol...tipycal phrase from mans to women...

....women tipical answer... promises ...promises...

Saludos

Last edited:

Growmau5

Well-Known Member

@salmonetin I appreciate the comments and constructive criticism.

The metal ones I used are just fine. I did some stress testing to them, jiggling them around and such. The connections are solid. But I agree, these would be better... Ill used them next time::

On the AC side, I like removable power cords, the same ones used in hundreds of thousands of HPS ballasts hanging in grow rooms across the world. If its good enough for all of them, its good enough for me...

Firstly, my priorities are safety and cleanliness, I could care less about waterproofing, IP or UL listing and I am not trying to sell these lights. My choice in connectors is based on cool shit I find on amazon....i saw waterproofed connectors mixed with non-waterproof connectors... for my pov its a bit nonsense

Companies enclose these meanwell drivers inside of hot metal fixtures all the time. My little junction box sitting with a 1/2" air gap in front of the drivers isnt going to do jack to the temperature or longterm function and reliablility of the drivers.. I don't know wtf ur talking about here... additionally, the drivers include about a foot of wire to work with, without having to solder an extension. thats why I did it this way. Thats one less connection point per driver (x4)i dont like to put nothing over the drivers...i put the junction box beside of drivers not over the drivers...better on passive way...for long runs..

I was referring to these ones , which do suck..but the female ones suck and about 25% of them have poor contacts.

The metal ones I used are just fine. I did some stress testing to them, jiggling them around and such. The connections are solid. But I agree, these would be better... Ill used them next time::

On the AC side, I like removable power cords, the same ones used in hundreds of thousands of HPS ballasts hanging in grow rooms across the world. If its good enough for all of them, its good enough for me...

Growmau5

Well-Known Member

There was some discussion on another thread about Gavita jumping into the LED game with in the next few years. Well, it looks like they already are! It was proposed that we wouldn't see a Gavita LED grow light for at least another year, so they can milk the "newish" double ended HPS setups. If that is indeed Gavita's strategy, I think its a good one, while waiting for chip prices to drop and gaining experience in the aquarium lighting industry. I thought I would share this article for anyone who is interested.

EfficientWatt

Well-Known Member

Hi Growmau5

I quite like your last 700mA / lens build, looks really clean, nice job !

Good job on the wiring too, it's well disguised .. which made me think/question :

- Do you find the lens to have a good seal, water projection proof according to KB, what are your impressions ? (there is a plastic seal with those lenses ?)

- I assume you drilled a hole for each cob for the wiring to come in and out, and run on the back of the HS, did you seal that hole with silicon or something ?

Thanks for sharing and again ... impressive work !

I quite like your last 700mA / lens build, looks really clean, nice job !

Good job on the wiring too, it's well disguised .. which made me think/question :

- Do you find the lens to have a good seal, water projection proof according to KB, what are your impressions ? (there is a plastic seal with those lenses ?)

- I assume you drilled a hole for each cob for the wiring to come in and out, and run on the back of the HS, did you seal that hole with silicon or something ?

Thanks for sharing and again ... impressive work !

Last edited:

Growmau5

Well-Known Member

no problem. from the heatsink, the height is just slightly more than 1.5" but not quite 1 9/16". basically, 1/32 over 1.5"Hey @Growmau5 ! Very nice build, looks pro!

Got a question for you - I can see that you're using Ledil reflectors (# F13838_ANGELINA-XW, right?) in your previous build. Could you be so kind and measure its height from the HS (that is holder+adaptor+reflector) for me?

Thanks for stopping by. The KB lenses have a really well designed Silicon Rubber seal. It fits securely around the entire lip of the glass lens and has a very nice seal. I secured it with just 2 out of the 4 possible screws. I did a quick test running water from my kitchen sink over the lens and heatsink, it stayed completely dry inside. I was impressed.Hi Growmau5

I quite like your last 700mA / lens build, looks really clean, nice job !

Good job on the wiring too, it's well disguised .. which made me think/question :

- Do you find the lens to have a good seal, water projection proof according to KB, what are your impressions ? (there is a plastic seal with those lenses ?)

- I assume you drilled a hole for each cob for the wiring to come in and out, and run on the back of the HS, did you seal that hole with silicon or something ?

Thanks for sharing and again ... impressive work !

-I did indeed drill a hole on either side of the cob holder for wiring & used a small dab of silicon to seal the hole. I also use tiny dabs of hot glue to keep my solid core wire tacked down while the silicon dries.

One other comment on the KB lenses, they appear to be made of very soft glass ( possibly low iron glass). You can see very fine abrasions from manufacturing, shipping & handling. Terry cloth towels for cleaning is a no no, microfiber only is what I learned.

Additionally, I cleaned about half of the lenses with rubbing alcohol, installed them, & there appeared to be slight residue. One of those eco friendly glass cleaners would probably be best on the soft glass, I used windex.

Last edited:

BobCajun

Well-Known Member

Growmau5, you have red LEDs on hand, right? could you do an experiment to see what happens when you flower a plant under pure red light? See how many g/w you would get and how the potency compares. It would be interesting to find out. Reds are more efficient than whites, aren't they? I know it's possible to grow Cannabis with red filtered light but there's no data on yields or potency. I wouldn't grow them from seed under red only, because they probably need full spectrum to establish all the systems properly. But just for flowering I think pure red might actually be an improvement over white or blue/red.

Growmau5

Well-Known Member

i feel like this thread is covering that topicGrowmau5, you have red LEDs on hand, right? could you do an experiment to see what happens when you flower a plant under pure red light? See how many g/w you would get and how the potency compares. It would be interesting to find out. Reds are more efficient than whites, aren't they? I know it's possible to grow Cannabis with red filtered light but there's no data on yields or potency. I wouldn't grow them from seed under red only, because they probably need full spectrum to establish all the systems properly. But just for flowering I think pure red might actually be an improvement over white or blue/red.

https://www.rollitup.org/t/testing-osrams-150w-horticultural-led-fixture-v1-monochromatic-dream-or-nightmare.867782/

I have like 6 deep reds on hand right now, not enough to build something to produce a decent result.

BobCajun

Well-Known Member

Oh okay. Thanks for pointing me to that thread then.i feel like this thread is covering that topic

https://www.rollitup.org/t/testing-osrams-150w-horticultural-led-fixture-v1-monochromatic-dream-or-nightmare.867782/

I have like 6 deep reds on hand right now, not enough to build something to produce a decent result.

BobCajun

Well-Known Member

No that was just somebody using an Osram 16 red/5 blue panel. Oh well, from everything I've read I don't think any single band or combination of a few single bands is significantly different from white anyway. Since white is easy to get as floodlights or high bays not much point in going to the extra trouble of finding or making red lamps. I was just curious how pure red would turn out.i feel like this thread is covering that topic

https://www.rollitup.org/t/testing-osrams-150w-horticultural-led-fixture-v1-monochromatic-dream-or-nightmare.867782/

I have like 6 deep reds on hand right now, not enough to build something to produce a decent result.

Last edited:

Michael Huntherz

Well-Known Member

That is a thing of beauty, truly. I'm fantastically envious, and dreaming of the future. I really like the passive cooling design, so clean. Way to rock.As simple as this passive setup looks, I put a hell of a lot more time into building it than I anticipated. I am having that feeling right now where I could die happily if I never have to sand, drill or tap another heatsink ever again. ..

Joking of course, I love this shit too much. But I will definitely need a breather before starting any new projects.

View attachment 3517561 View attachment 3517562

Last edited:

kony brado

Well-Known Member

hi,im new here and realy like your fixture(sorry for my bad spelling),i decided to try diy after whacing u on utube,great work man,i want to build somthing like this with 4 cxb 3950 per bar,and to power them to 1050ma,32 cob for the space of 110*200cm(i think its somthing like 24 sqare feet),i usualy go with 2 hps 600 and get a grame per w (1200g),i wanted to ask u if i can go with hlg 120h-c1050a to power 4 cxb3950 in one light bar? thanks for shering the light

Growmau5

Well-Known Member

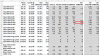

according to Supras spreadsheet, looks like it will fit 4.4 cxb3590hi,im new here and realy like your fixture(sorry for my bad spelling),i decided to try diy after whacing u on utube,great work man,i want to build somthing like this with 4 cxb 3950 per bar,and to power them to 1050ma,32 cob for the space of 110*200cm(i think its somthing like 24 sqare feet),i usualy go with 2 hps 600 and get a grame per w (1200g),i wanted to ask u if i can go with hlg 120h-c1050a to power 4 cxb3950 in one light bar? thanks for shering the light

kony brado

Well-Known Member

thanks 4 the info mau5,it is much apritiatod,im looking for the next episod

appreciated. Lolthanks 4 the info mau5,it is much apritiatod,im looking for the next episod