nfhiggs

Well-Known Member

How many watts of LEDs do you need to cool?

How many watts of LEDs do you need to cool?

Not sure what you are on about here....It appears they do parallel strings. You may get away with it with CoBs, but not strings of LEDs. They are going to have customer support issues up the ass, if people buy their shit.

-

Finally, someone gets me.Man you are one ornery old cuss.

Bait or troll never entered my mind.not trying to bait or troll.

I think UV is very specie dependent. I asked one of the professors about it. He answered while subconsciously shaking his head no, he said some stuff way the fuck over my head, but used the word shock and something about signalling . Unless you know what you are doing with UV, do not use it. You are doing fine with out it. If you have an isolated plant you want to experiment with then go for it. I believe they cited studies of UVB but I think their UV emitter is UVA. I do not want to go back and fact check that one.UV channels

High density is not a good thing. You want things spread out good for thermal and uniformity. The BLM SPYDR is considered a good design.high density of the board design

No, I think they are stupid for selling a product that can kill their customer. 100VDC or more I will not touch. I'm too careless. You've got to know your limitations.Do you think the design is any more dangerous to assemble

Chilled does provide the umol/j on the reports page, their lights are sphere tested.Finally, someone gets me.

The watts belongs hidden in the technical specifications. Watts should NOT be used to define the fuckin' unit!

How about some professionalism for once. I like heliospectra. They are professionals. Me not so much. I had the Heliospectra units doing a light show in sync with music.

Normal? Can't even imagine how awful that must be.

If you're trying to be normal, you will never know how amazing you can be.

Overcome the notion that you have to be normal. It robs you of the chance to be extraordinary.

I think you're way too paranoid about the voltage.No, I think they are stupid for selling a product that can kill their customer. 100VDC or more I will not touch. I'm too careless. You've got to know your limitations.

It's no better than the Quantum Board. If you can be patient, I'll hook you up with some PCBs. If necessary, I'll show you how to solder the SMD parts. It's easy.

Yeah, they'd be okay if I didn't know how to make a PCB.what do you think about the typical diy string of discrete diodes

I'm not being paranoid. I won't touch it because I am that careless. But as far as selling a product, it is insane to take on that liability. And I suspect it is technically a schlock job which will bite them in the ass.I think you're way too paranoid about the voltage.

Parallel strings driven with a shared CC driver will experience thermal runaway. When one string operates at a slightly different temperature than the other, the voltages will change, the current will change the temperature will change and over time one sting will be drawing most of the current. CoBs are matched pretty well in voltage and temperature, so it would take a long time, like days for it to happen if they were left on 24/7. If I were to fire up one string wait a minute then add the second string they would start out with a significant thermal imbalance, within 12 hours one would be burning up, the other flickering out. If I switched which one I fired up first then the other would flicker out. The more LEDs in the string, the higher the voltage mismatch, and the greater the difference in temperature the more likely it will happen.Not sure what you are on about here..

"will"?Parallel strings driven with a shared CC driver will experience thermal runaway.

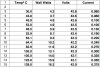

Maybe I am just unlucky. It happened to me 100% of the time. Two strings on separate boards no heatsinks, forward voltage 42.2V and 42.4V, 16 LEDs each, white Luxeon Rebel ES, do not remember the current, it had to be under 300mA shared, less than 150mA each.many many many examples of parallel builds in this forum. not a single case of thermal runaway

How many products do you buy where you look at the wattage first? I could care less what the wattage is. The PPFD per watt, yes. These LED grow light hucksters sell their stuff like snake oil, they drive me nuts. I want a product description and tech specs. But this is over the top Real 1200 watt power draw – none of the silly marketing nonsense with “LED watts vs Electrical watts”. Using the phrase "Real 1200 watt power draw" is silly marketing nonsense itself. The pot calling the kettle black.most consumers will first look at wattage.

And those number look good. After knowing that, why would I care about the wattage?Chilled does provide the umol/j

Sphere testing LED fixtures bugs me. It's like LED lighting guys are stuck with a light bulb mentality. A sphere is for measuring isotropic flux, like from light bulbs. They also measure Intensity but I want irradiance not steradian intensity. A flat surface, (i.e. irradiance) pattern in terms of PPFD is what I'd like to see. Sphere measurements have nothing to do with what reaches the plant. It skews the µMoles/J by inflating the number of photons because it includes the photons that would not reach the plant.their lights are sphere tested.

I was kinda kidding about the ice maker, I did consider it though. The plan is to keep adding fixtures until the water starts getting warm so I know the thermal capacity. A friend of mines son is moving to Oregon next week to run a $Million indoor cannabis grow facility. So if things work out hopefully a lot of kW. Unfortunately I am not ready for them yet.How many watts of LEDs do you need to cool?

Write that down on a sheet of 8.5 x 11 linen bond paper, fold, insert in #10 envelope, and send it to someone that gives a shit what you think.I think you've mainly come here to lecture

because thats how 9 out of 10 growers size a roomAnd those number look good. After knowing that, why would I care about the wattage?

Good to know there is at least 1 out of 10 with some brains.because thats how 9 out of 10 growers size a room