ketchup45685224

Well-Known Member

Hi,

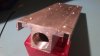

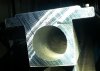

I have a couple hundred feet of aluminium extrusions designed for LED COB cooling. The hole in the middle is sized for a 1 1/4 inch NPT thread (standard pipe thread found at any hardware store). I'd need about $2 per inch to cover cost. Is it worth it to sell this stuff?

I have a couple hundred feet of aluminium extrusions designed for LED COB cooling. The hole in the middle is sized for a 1 1/4 inch NPT thread (standard pipe thread found at any hardware store). I'd need about $2 per inch to cover cost. Is it worth it to sell this stuff?