Thinking of a new light ..

- Thread starter stardustsailor

- Start date

stardustsailor

Well-Known Member

Yes ,there's a reason ..Any reason not to have the drivers outboard? Less heat no?

The same reason ,that the heatsinks ,fans,Arduino,etc are not outboard !! LOL !!

Less Heat ?

I do not think that this is going to be a problem ..

Deforming of the steel case ,-due to excess negative pressure - might be one ...

( No,I'm kidding ...Case is made out of really rigid steel sheet ... Still ...)..

Or ..

Forming of ice crystals on the heatsink ,might be another one !!!

(Ha-ha-ha .... Now I'm definately kiddin' around ...

...Led -born weed ,remember ? )

...Led -born weed ,remember ? )No,Pet ...

I want everything inside a box ..

A case ...

" Sunlight Enclosed " ..

Yeah ....

That's the name .....

"

SDS OptoLabs LTD ,is soon to be releasing the new

Cree CXA3070 ,COB based horticultural LED illumination fixture,

under the name " XA 37 SE ",where SE does not stand for

Special Edition but for " Sunlight Enclosed ".

The light will feature .blah...blah..blah..Wow! ..blah.. ..Yes ! ...blah... !

"

(Along with everything else,Pet ...

Last edited:

stardustsailor

Well-Known Member

!@#$%....

Metal working with a drill press , a dremel and some files ain't an easy job ...

But those're my main tools right now ...

So it proceeds ,rather slowly ...

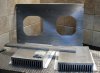

That is the " air restrainer lid " of the two heatsink 'modules' ...(upside down )

Still under work (with a file and sand paper .... ...)

...)

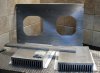

With the two heatsink modules .....( 2 kgs / ~4 pounds each )

And it's going to be like that ....(more or less ..still needs work ...)...

Also two parallel alum bars ( of " Π " profile ) they are going to support the lid ,length-wise (near the openings).

Just for a rough idea of the 'internal' looks ....

Hand painted the plexi (from the inner side ) black .....

In order to look like this :

Metal working with a drill press , a dremel and some files ain't an easy job ...

But those're my main tools right now ...

So it proceeds ,rather slowly ...

That is the " air restrainer lid " of the two heatsink 'modules' ...(upside down )

Still under work (with a file and sand paper ....

...)

...)

With the two heatsink modules .....( 2 kgs / ~4 pounds each )

And it's going to be like that ....(more or less ..still needs work ...)...

Also two parallel alum bars ( of " Π " profile ) they are going to support the lid ,length-wise (near the openings).

Just for a rough idea of the 'internal' looks ....

Hand painted the plexi (from the inner side ) black .....

In order to look like this :

stardustsailor

Well-Known Member

With 4x CXA3070 3000K ,bin Z4 ?How big of a foot print do you anticipate?

At 350-1950 mA ?

With ~115° 50%p emission angle ?

If cooling is going to worksas expected ?

More than enough for my 1x1 m space ( 3' x 3' )....

For sure ,more than enough ...

stardustsailor

Well-Known Member

Lately I try to be a...minimalist ,regarding my designs ...

Well,at least I try to ..

See ?

One knob !

Which BTW except being a dimming pot ,is also an on/off switch {off position :farthest counter clock wise } !!!

(How minimal is this ? This 5 gram knob is attached to more than 10 kgs of metal and high-tech electronics...

It takes serious efforts to be a minimalist ...Specially with weed ...and the custom led designs to grow ...)

Well,at least I try to ..

See ?

One knob !

Which BTW except being a dimming pot ,is also an on/off switch {off position :farthest counter clock wise } !!!

(How minimal is this ? This 5 gram knob is attached to more than 10 kgs of metal and high-tech electronics...

It takes serious efforts to be a minimalist ...Specially with weed ...and the custom led designs to grow ...)

stardustsailor

Well-Known Member

Next steps will be on the heatsink modules and the restrainer lid ...

Some more drilling for screws and wiring ..

And then to array holder positioning ..

drilling holes for the screws ..Tap 'em (M3 ) ..

And then temporarily ,the "restrainer lid- heatsink modules" combo will be left aside ...

Square openings have to be cut to the steel sheet bottom of the case ,in order for the heatsinks to protrude

~ 30 mm ...

( ~10 mm is the height of the intermediate "air chamber " between restrainer lid and case's bottom panel..)

And still will be not even close to half way ,from being fully completed and operational ready ...

Oh ...I get tired ,just thinking of what has still to be done ....

Of every little detail...

PS : A bit of grinding was done to the IDEAL array holders ,in order to 'reveal' the Tc point ...

stardustsailor

Well-Known Member

I like my (weird ? ) combination of colors ...

White and silver ..(mainly ) ...

LOL...

White and silver ..(mainly ) ...

LOL...

stardustsailor

Well-Known Member

salmone

Well-Known Member

PS : A bit of grinding was done to the IDEAL array holders ,in order to 'reveal' the Tc point

..send a photo ...or both... to a IDEAL maybe corrected in the future... ...great design flaw no place to contemplate a thermistor or thermocuple...

...something like that...

...but finished or corrected... ...and i will like to see this photo finished or corrected...

I encourage to you teacher... master... great work

muchos animos sds

saludos

..send a photo ...or both... to a IDEAL maybe corrected in the future... ...great design flaw no place to contemplate a thermistor or thermocuple...

...something like that...

...but finished or corrected... ...and i will like to see this photo finished or corrected...

I encourage to you teacher... master... great work

muchos animos sds

saludos

Last edited:

stardustsailor

Well-Known Member

Ok..

With a bit of Saturday's morning metal work ...

At last the "freezer" thing of the CXA's is one piece !

(...)

LOL...Made out of other pieces ....

The upper side (the one facing the fans )....

Thew bottom side (the one facing the plants ! LOL! )

....

And 'cause everything is 100% hand -made and not by a robotic CNC ,drill ,whateva ...

Ok,...

It is absolutely natural ,some holes for screws to differ slightly in placement ...

So ,' align / correct fit marks ' are more than handy !

A detail pic ...

And ..Inside ...the cas...guh...the sidewalls of the case ....

Space monkey ,knows how to build some real led grow lights ,ain't that so ?...

With a bit of Saturday's morning metal work ...

At last the "freezer" thing of the CXA's is one piece !

(...)

LOL...Made out of other pieces ....

The upper side (the one facing the fans )....

Thew bottom side (the one facing the plants ! LOL! )

....

And 'cause everything is 100% hand -made and not by a robotic CNC ,drill ,whateva ...

Ok,...

It is absolutely natural ,some holes for screws to differ slightly in placement ...

So ,' align / correct fit marks ' are more than handy !

A detail pic ...

And ..Inside ...the cas...guh...the sidewalls of the case ....

Space monkey ,knows how to build some real led grow lights ,ain't that so ?...

Last edited:

stardustsailor

Well-Known Member

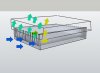

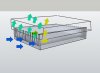

Some cooling notes :

Estimation for one heatsink and 2x CXA3070's operating @1950 mA

CXA thermal conductive surface : 27.35 x27.35 mm = ~748 mm^2

Applied at calculator :

Surface 2x 748= 1496 mm^2 ....Square root =~38.67 ..

So a hypothetical square chip with 38,67 mm sides was 'placed' ..

Heat to be dissipated : 100 Watts .

Flow rate of 2x fans combined @ 12 V : 200CFM ..

TIM thickness : 0.2 mm ( a sloppy job 200 micron layer )

~42°C Case temperature ....

A rough estimation ...

Not bad at all ...

I chose parallel operation for the 4x fans ....

Instead of 'series' ...

....

Maybe I should consider 2x2 ... A parallel combo of 2x " double in series " fans ...

Bulky ! ..It needs free 50 mm depth from inner side of top lid ...

The whole case is about 80 mm ... Not much space ...

Anyway ...

Remember that simply, parallel fans increase volume of air moving (flow rate ) keeping same pressure level,while series fans increase pressure ,keeping same flow rate level ..

Vertical air flow is guided ..

A tad of resistance is added ( the restrainer lid ) ,in order ,to "concentrate" the air intake ,more

into the middle(center ) fins and less at the side-fins of the heatsink ..

The CXA's will be placed at the center of the heatsink,length-wise.

The whole idea is to guidethe -massive- air flow towards being 'sucked in ' and 'run through' the center fins ,

until it 'exits' on the inner of the box ,to cool the rest of the electronics,before gets blown out from the 4x parallel fans ..

The compromise in the general air-flow is negligible ,compared to the higher ,'targeted' airf flow towards the center of the heatsinks ,allowing for more efficient ACTIVE cooling of that part .Instead of letting the heatsink 'suck ' in free flowstate ,with most of air escaping upwards to be blown out ,

the restrainer lid ,keeps the air flowing for a bit longer and futher 'down' the fin channels (mainly the center ones ) ,allowing for more fin surface to convect heat with cool air ,before it just gets blown out of the case ....

Thus more efficient cooling .

BTW ...

Did you know that free-fall parachutes have a 'restrainer' thing ,

to slow down the 'opening/engagement ' of the parachute ?

Oftenly ,things have to last longer and /or go further ....

Not only vertical-wise ...

Forced air volume,passing through horizontal heatsink fins is such a case ,also...

Estimation for one heatsink and 2x CXA3070's operating @1950 mA

CXA thermal conductive surface : 27.35 x27.35 mm = ~748 mm^2

Applied at calculator :

Surface 2x 748= 1496 mm^2 ....Square root =~38.67 ..

So a hypothetical square chip with 38,67 mm sides was 'placed' ..

Heat to be dissipated : 100 Watts .

Flow rate of 2x fans combined @ 12 V : 200CFM ..

TIM thickness : 0.2 mm ( a sloppy job 200 micron layer )

~42°C Case temperature ....

A rough estimation ...

Not bad at all ...

I chose parallel operation for the 4x fans ....

Instead of 'series' ...

....

Maybe I should consider 2x2 ... A parallel combo of 2x " double in series " fans ...

Bulky ! ..It needs free 50 mm depth from inner side of top lid ...

The whole case is about 80 mm ... Not much space ...

Anyway ...

Remember that simply, parallel fans increase volume of air moving (flow rate ) keeping same pressure level,while series fans increase pressure ,keeping same flow rate level ..

Vertical air flow is guided ..

A tad of resistance is added ( the restrainer lid ) ,in order ,to "concentrate" the air intake ,more

into the middle(center ) fins and less at the side-fins of the heatsink ..

The CXA's will be placed at the center of the heatsink,length-wise.

The whole idea is to guidethe -massive- air flow towards being 'sucked in ' and 'run through' the center fins ,

until it 'exits' on the inner of the box ,to cool the rest of the electronics,before gets blown out from the 4x parallel fans ..

The compromise in the general air-flow is negligible ,compared to the higher ,'targeted' airf flow towards the center of the heatsinks ,allowing for more efficient ACTIVE cooling of that part .Instead of letting the heatsink 'suck ' in free flowstate ,with most of air escaping upwards to be blown out ,

the restrainer lid ,keeps the air flowing for a bit longer and futher 'down' the fin channels (mainly the center ones ) ,allowing for more fin surface to convect heat with cool air ,before it just gets blown out of the case ....

Thus more efficient cooling .

BTW ...

Did you know that free-fall parachutes have a 'restrainer' thing ,

to slow down the 'opening/engagement ' of the parachute ?

Oftenly ,things have to last longer and /or go further ....

Not only vertical-wise ...

Forced air volume,passing through horizontal heatsink fins is such a case ,also...

Last edited:

PetFlora

Well-Known Member

Holy CrapWith 4x CXA3070 3000K ,bin Z4 ?

At 350-1950 mA ?

With ~115° 50%p emission angle ?

If cooling is going to work as expected ?

More than enough for my 1x1 m space ( 3' x 3' )....

For sure, more than enough ...

And the umoles at the perimeter?

stardustsailor

Well-Known Member

I'm not sure what exactly you mean ...Holy Crap

And the umoles at the perimeter?

'( English ,you know that is not my mother-language...)

Perimeter ?

a) AI'm a fan of diffused light,wide emission angles ...

b) I do not grow in a 3'x3' greenhouse ! LOL...

It's merely a tent and has reflective walls...

c) Photons bounce and/or get absorbed..( Once they do not 'escape ' the 'site' ,firstplace )....

Explain,please ...

PetFlora

Well-Known Member

Sure,I'm not sure what exactly you mean ...

'( English ,you know that is not my mother-language...)

Perimeter ?

a) AI'm a fan of diffused light,wide emission angles ...

b) I do not grow in a 3'x3' greenhouse ! LOL...

It's merely a tent and has reflective walls...

c) Photons bounce and/or get absorbed..( Once they do not 'escape ' the 'site' ,firstplace )....

Explain,please ...

to get a visual, go to A51 and see their umole charts showing umoles at 1-2-3 feet directly below the panel and 1 x 2 -3 feet to the sides

so your tent perimeter is 1m x 1m

Perimeter is the area bordering a physical space

It will be enlightening to see how yours compares, especially considering the 2 cobs virtually centered in the tent are point source lights

One of many things I like about the BML Spydr 600 is, each bar is 3ft x 6 bars (~ 3m x 3m), so overall light/umoles is very homogenous

PSUAGRO.

Well-Known Member

I'll take two!

Not so fast.............their is a waiting list!!

Excellent work as always mr sds................I wonder if guod has gone the cob route as well with his current builds??, can't beat the #'s/"simplicity" ATM.

stardustsailor

Well-Known Member

I should 've expected that one comin' ...Sure,

to get a visual, go to A51 and see their umole charts showing umoles at 1-2-3 feet directly below the panel and 1 x 2 -3 feet to the sides

so your tent perimeter is 1m x 1m

Perimeter is the area bordering a physical space

It will be enlightening to see how yours compares, especially considering the 2 cobs virtually centered in the tent are point source lights

One of many things I like about the BML Spydr 600 is, each bar is 3ft x 6 bars (~ 3m x 3m), so overall light/umoles is very homogenous

Well .Hmm ...

Let me put it this way :

This is not a led light you see being builded ..

No !

It is a HID light !

(High Intensity Diode )

Yes ! Do not laugh! I'm serious !

It is the HID of 'new era ' in grow lights ..

It is the High Intensity Discharge killer ...

The new 'species' in single-point horticultural illumination ...

It does not use multiple leds ...It uses kinda a huge- big-heavy - aluminium 'mega' 'diode'

,made out of >5kgs of aluminium for it's case and of 4x CXA3070 Chips ...

(Now ...THESE chips use leds ....Not the light ! )

So ...It can't compare with rest/any of the led lights 'cause ain't one ( Guh ..) ...

It can compare with it's 'kind' only ...

The ones yelling at me ,-every time -when I enter a grow tent's/ room's arena :

'Ave Stardust ! Morituri te salutant ! '

My light is meant to 'slaughter' ALL ghosts from past ...

ESPECIALLY The ones with the amber halo...

With no 'poor'excuse ,like 'light /power spread' ...

" With it's dick covered with sand',as we say in my homeland ..

That's how It's going to deal with 'em !

Ha-ha-ha-ha-

I'm nuts ..

That's it !

I love the led weed !

Last edited:

tenthirty

Well-Known Member

3x3 x50w a sq ft= 450watts. That is the rule of thumb for HPS.

Hmmmmmm.

4 ea CXA3070 3000K Z4 @ 1.4A = 52W @ 39.3% efficient........

That would be 208 watts to cover the same 9 sq ft.

23.1 watts per sq ft.

Comments???

I sure as hell hope this works!!!!!!

At 40w sq ft of combined led and cmh, I get 50.5 grams per sq ft.

I would love to cut my power bill roughly in half!!!!!!!

Hmmmmmm.

4 ea CXA3070 3000K Z4 @ 1.4A = 52W @ 39.3% efficient........

That would be 208 watts to cover the same 9 sq ft.

23.1 watts per sq ft.

Comments???

I sure as hell hope this works!!!!!!

At 40w sq ft of combined led and cmh, I get 50.5 grams per sq ft.

I would love to cut my power bill roughly in half!!!!!!!