CobKits

Well-Known Member

I was looking for a better way to quantify the output and efficiency of COBs vs the newer PCBs (in absence of a 2m sphere, and in absence of any real low-current COB sphere data out there). The sphere i usually use to do COB testing is 20" and i usually put the COBs just outside shining into its 2" port. The large size PCBs didnt really work here, as putting it inside the sphere created a lot of surface area for absorbance, skewing the results. My first attempt at quantifying output was to use the same aluminum substrate the PCB is on, and mount a single COB to the back of it.

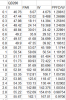

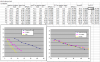

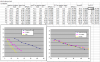

The idea was that i could test a PCB or a COB and have the same hardware inside the sphere. I mounted an ideal holder so i could test various 28mm cobs. Thats an HLG first gen QB, and i tested a citi 1212 gen5 and a Luminus CXM22. So i tested the QB and the single COBs at various currents and plotted PPFD/W vs Watts.

of course the QBs smoked a single (small) COB but the idea was to determine what number of COBs equaled a QB. This was simulated by multiplying the single COB's PPFD/W output by arbitrary numbers to see what wattage (i.e number of COBs) would match the QB efficiency at a given wattage. As you can see, 3 CXM22s or 5 citi1212s did a pretty good job of approximating the QB

A reasonably fair test but biased for a number of reasons, not including the fact that the sphere stuffed with the awkwardly large (relative to sphere diameter) board might skew data, with the board throwing light in all directions and the COB being a (relatively) point source of light. Also the fact that the thin QB board wasnt really a ideal heatsink for the COB chips in terms of removing heat from the chip efficiently

On top of that both that model QB and that model COB used in that test are not current top-bin offerings.

I felt that i wanted to test a REAL multiple number of cobs in a real environment. So i rounded up a couple different models of current PCB offerings, and some of the latest cobs and erected a fresh 3x3 gorilla tent for dedicated testing. I made 5 marks on the bottom of the tent to take measurements at 5 different places to get good averages. i made care to make sure that the Li-Cor LI190 sensor was set in the same location and same relative orientation each time (leveling bubble toward me at 6 o'clock, cable at 2 o-clock)

The tent was light-proof when zipped up, so while the square geometry is not the ideal photometric measurement, i felt with the reflective walls and averaging multiple measurements, i would be able to get a good estimation of total PAR available and how it scaled with current. This 'total collection of light' approach was important due to the different sizes of COBs vs PCBs, i didnt want to take just a spot measurement at a distance due to the different way they throw light. Here's a pic of LI-COR with tent zipped up

all of the test boards were mounted at the same height, hung in free air approximately 12" down from the top to allow for some natural convection.

I mounted 8 ideal holders for COBs on an HLG slate 2 heatsink. Not ideal as its a relatively thin heatsink but decent for a simple test since were keeping the cobs well under 50W each. The COBs i'll be using in this intial test are Citizen 1212 gen6 3000k 80cri due to their relatively low cost. By connecting and disconnecting COBs I was able to do an 8-up and a 4-up test.

8-up test:

The idea was that i could test a PCB or a COB and have the same hardware inside the sphere. I mounted an ideal holder so i could test various 28mm cobs. Thats an HLG first gen QB, and i tested a citi 1212 gen5 and a Luminus CXM22. So i tested the QB and the single COBs at various currents and plotted PPFD/W vs Watts.

of course the QBs smoked a single (small) COB but the idea was to determine what number of COBs equaled a QB. This was simulated by multiplying the single COB's PPFD/W output by arbitrary numbers to see what wattage (i.e number of COBs) would match the QB efficiency at a given wattage. As you can see, 3 CXM22s or 5 citi1212s did a pretty good job of approximating the QB

A reasonably fair test but biased for a number of reasons, not including the fact that the sphere stuffed with the awkwardly large (relative to sphere diameter) board might skew data, with the board throwing light in all directions and the COB being a (relatively) point source of light. Also the fact that the thin QB board wasnt really a ideal heatsink for the COB chips in terms of removing heat from the chip efficiently

On top of that both that model QB and that model COB used in that test are not current top-bin offerings.

I felt that i wanted to test a REAL multiple number of cobs in a real environment. So i rounded up a couple different models of current PCB offerings, and some of the latest cobs and erected a fresh 3x3 gorilla tent for dedicated testing. I made 5 marks on the bottom of the tent to take measurements at 5 different places to get good averages. i made care to make sure that the Li-Cor LI190 sensor was set in the same location and same relative orientation each time (leveling bubble toward me at 6 o'clock, cable at 2 o-clock)

The tent was light-proof when zipped up, so while the square geometry is not the ideal photometric measurement, i felt with the reflective walls and averaging multiple measurements, i would be able to get a good estimation of total PAR available and how it scaled with current. This 'total collection of light' approach was important due to the different sizes of COBs vs PCBs, i didnt want to take just a spot measurement at a distance due to the different way they throw light. Here's a pic of LI-COR with tent zipped up

all of the test boards were mounted at the same height, hung in free air approximately 12" down from the top to allow for some natural convection.

I mounted 8 ideal holders for COBs on an HLG slate 2 heatsink. Not ideal as its a relatively thin heatsink but decent for a simple test since were keeping the cobs well under 50W each. The COBs i'll be using in this intial test are Citizen 1212 gen6 3000k 80cri due to their relatively low cost. By connecting and disconnecting COBs I was able to do an 8-up and a 4-up test.

8-up test:

Last edited: