wietefras

Well-Known Member

It's really pointless for us to try and explain this in physics principles since you are still unable to apply it and flat out ignore the truth when presented to you on a silver platter.There are many reasons that could happen. The inverse square law not being one of them.

Reflection would be there at each height so unlikely reflection would be a major factor.

And this overlap you speak of. Got any citations to back that up? Overlap will follow the inverse square law.

Even your own measurements and calculations have demonstrated that inverse square law does not apply to distance between fixture and canopy. Malocan did the same with a spectrometer and many others have done it with lux meters. It's really time you stop the cognitive dissonance and let the truth in.

If you really want to see this for yourself, why not build an actual growlight? You pretend to be a "growlight researcher" so how difficult can that be? Hang the damn thing in your tent and find the optimal height for uniformity (whole surface covered up with darkest spots still getting at least 80% of average). Double the distance and see if intensity was cut to 25% of the first measurement.

If you want to do it properly you should measure average light intensity over the whole surface. Single point measurements are unreliable. Measuring the average will also correct for when you got the uniformity wrong (distance too close) and for small measuring errors (wrong angle, wrong position). That is if you have learned how to correctly calculate averages since the first time you appeared here as nofucksgiven. Otherwise just stick with one measurement for each height.

BTW Do you also remember how you were applying "inverse square corrections" to your PPFD measurements back then? Good times, good times.

Wrong. The lumen CIE curve extends all the way from 380nm to 780nm. The amplitude is less at the extreme ends, but it's still measured and therefore it works perfectly fine to measure light of any (visible) color.Lux meters typically measure the number of photons between 500nm and 600nm

The sensors used in Lux meters are similar (if not the same) as those used in cheap PAR meters. They are also sensitive over the whole range.

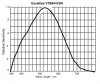

For instance this one:

For a lux meter they add a color filter to tone down the blue and red ends. For a cheap PAR meter they add a color filter to squeeze the chart into more of a box shape.

Either way, if the lux meter provides a reading, it's reading the light and it can be used perfectly for relative light intensity comparisons and also for guesstimating PPFD values well within the 600% range that plants can deal with.

Oh and while we are at it. Malocan's spectrometer produced both PPFD and Lux values. If you divide those lux values by the corresponding PPFD they give you exactly the same Lux to PAR conversion factors like we calculate with Alesh's chart or like Apogee posts on their site. Amazing coincidence since that's impossible right?

Funny how the measurements showed exactly what I (and others) told you they would show and exactly the opposite of what you claimed. So there.You would know that if you had the ability to understand optical measurement.

Finally you say something which is correct. Wow.You know a lot about this stuff.

)

)