Right there where you said "5W", that's inefficient. An entire ohm is out of the ballpark. A whole ohm might be used if the current is less than 100mA.

For me, on the LM3414 driver, efficiency is the difference between an inefficient 0.200 ohm inductor resistance vs. a 0.05 ohm inductor (all current to the LEDs goes through the inductor).

That's why we use drivers, they are A LOT more efficient than a resistor.

If I don't care about efficiency I'll use an on-board 0.01 ohm, 1% resistor.

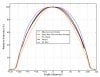

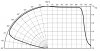

To measure current with a resistor, this is the resistor I use:

View attachment 3929544