Heres a little break down with pics. (Sorry if stuffs not with right pic im on phone and trying to keep this as detailed and near as I can...plus im baked soooooo

)

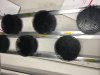

First I take the COB/Sink (referred to as unit from here on out) and lay it in my track where id like it to go, roughly marking center of unit on the frame(this is only for screw holes to hold it so screws arent as important as much as where on the frame you put it, thatll be up to each persons build)

Next I take a small ruler and align dots as best as possible and draw a line on the frame which will than get center punched on that line and than drilled out.

Once both holes are drilled, prop fixture up and hold unit in place. Take drill and put in holes of frame and just mark unit with drill, (enough for next step, sorry couldnt do above and take pic but you should see what i mean)

Take unit out from frame to finish next steps. Center punch that mark you just made on the unit. Followed by switching to your tapping bit and drilling a hole deep enough for desired screw.

Followed by tapping out the hole...(will add more pics in bit)

Introducing the manmade sun, inside.

Introducing the manmade sun, inside. )

)