Astir Grow Led Panel Project...

- Thread starter stardustsailor

- Start date

shaggy2dope

Active Member

wow just smoked a fattie and stumbled across this thread. I'm still picking pieces of my brain off the ground. Blew my mind. Great read.

I have seen the white light, and it's beautiful.

rep for all the big words

I have seen the white light, and it's beautiful.

rep for all the big words

tenthirty

Well-Known Member

Yes! I agree completely, but we've been looking at how discreet (more or less) wavelengths effect photo-morphology. If you will, how efficiently a given wavelength will facilitate electro-chemical reactions within the plant cell.

As far as I have found, nobody really knows how a plant cell cracks co2 into carbon and o2 or if the plant has the ability to mix or steer the photons of different wavelengths. Also does resonance play a role in all of this?

The way to NW for me, was/is a natural progression of experimentation from PLL to T5 to HPS to led. Also, the question arises, what is a good starting point? "Occam's razor"

As far as cheep Chinese leds, (good, fast, cheep.) pick 2, though a little natural selection here couldn't hurt. It could be said that some of the best scientific breakthroughs were mistakes!

Having a data sheet is a plus.

But I can't fault your logic here, but for me the price of a given diode is not as important as the price of electricity, cooling and most importantly my time, which is in very short supply!

Also, 10w led for $9.00 on a star. http://www.rapidled.com/cree-xm-l-neutral-white-led/

That's less than a dollar a watt. (looks like they run best at around 6w) I have a pile of these sitting on the table calling me.

I'm about to be able to compare these "top of the line" chips against the existing pro-grows that I have. Let's hope for a pleasant surprise.

As far as I have found, nobody really knows how a plant cell cracks co2 into carbon and o2 or if the plant has the ability to mix or steer the photons of different wavelengths. Also does resonance play a role in all of this?

The way to NW for me, was/is a natural progression of experimentation from PLL to T5 to HPS to led. Also, the question arises, what is a good starting point? "Occam's razor"

As far as cheep Chinese leds, (good, fast, cheep.) pick 2, though a little natural selection here couldn't hurt. It could be said that some of the best scientific breakthroughs were mistakes!

Having a data sheet is a plus.

But I can't fault your logic here, but for me the price of a given diode is not as important as the price of electricity, cooling and most importantly my time, which is in very short supply!

Also, 10w led for $9.00 on a star. http://www.rapidled.com/cree-xm-l-neutral-white-led/

That's less than a dollar a watt. (looks like they run best at around 6w) I have a pile of these sitting on the table calling me.

I'm about to be able to compare these "top of the line" chips against the existing pro-grows that I have. Let's hope for a pleasant surprise.

stardustsailor

Well-Known Member

Hmmm....Yes! I agree completely, but we've been looking at how discreet (more or less) wavelengths effect photo-morphology. If you will, how efficiently a given wavelength will facilitate electro-chemical reactions within the plant cell.

As far as I have found, nobody really knows how a plant cell cracks co2 into carbon and o2 or if the plant has the ability to mix or steer the photons of different wavelengths. Also does resonance play a role in all of this?

The way to NW for me, was/is a natural progression of experimentation from PLL to T5 to HPS to led. Also, the question arises, what is a good starting point? "Occam's razor"

As far as cheep Chinese leds, (good, fast, cheep.) pick 2, though a little natural selection here couldn't hurt. It could be said that some of the best scientific breakthroughs were mistakes!

Having a data sheet is a plus.

But I can't fault your logic here, but for me the price of a given diode is not as important as the price of electricity, cooling and most importantly my time, which is in very short supply!

Also, 10w led for $9.00 on a star. http://www.rapidled.com/cree-xm-l-neutral-white-led/

That's less than a dollar a watt. (looks like they run best at around 6w) I have a pile of these sitting on the table calling me.

I'm about to be able to compare these "top of the line" chips against the existing pro-grows that I have. Let's hope for a pleasant surprise.

First things,first....

-Even if we knew everything about every wavelength of light,still it would be the worst option ,to supply these wavelengths ,using

different actinic leds ...(Monochromatic)....Most of them are unefficient and/or heavily dependant on Tj for effective operation...

Not to mention the spectral 'mixing' ( homogenizing ) difficulties and compromises...

-CO[SUB]2[/SUB] does not actually break into C & O[SUB]2[/SUB]...In,fact with the use of radioactive-isotopes ,we know that is the water that breaks (Photolysis)...

It has been proven that the O[SUB]2 [/SUB]evolved in PS originates from H2O, not from CO2.

-Resonance...Mhhh ...

The excitation energy in antenna pigments is transferred to the reaction center by fluorescence resonance

energy transfer, a non-radiative process with up to 95 to 99% energy transfer efficiency.

Let's see what other we know...

Light is funneled to two photosystems with the red-absorbing reaction center pigments P680 and P700

The light funnel consists of antenna pigments that absorb different colors of light.

By having P680 and P700 absorbing such long-wavelength/low-energy light, evolution has provided a pathway for photosynthesis to harvest virtually the entire visible spectrum!

"Emerson went on to study the effect of wavelength on photosynthesis. This kind of plot is sometimes called an "action spectrum", it shows how effectively various wavelengths drive photosynthesis. Superimposed on this plot we see the quantum yield as a function of wavelenth of the photons. In both sets of curves, you can see that photons of green wavelength are less efficient than those in blue and red wavelengths. Photons with wavelength beyond 700 lack sufficient energy to drive photosynthesis! Recall that blue wavelengths have higher energy than red wavelengths. This fact tells us that whatever pigments are involved in photosynthesis, they apparently have a minimum energy required to excite an electron that is found in a red photon. "

http://plantphys.info/plant_physiology/light.shtml

http://plantphys.info/plant_biology/photopart.shtml

Also.....

Shade Adaptations and Light Concentrating Mechanisms

Columnar superficial palisade cells allow efficient capturing of light despite the sieve effect (which arises

from gaps between chloroplasts that reduce absorption compared to chlorophyll in solution). Light

channeling may also divert light through the vacuole or the cell wall areas to facilitate transmission into

deeper layers of the leaf. The spongy mesophyll in the leaf interior has many reflecting interfaces which

cause light scattering and increase the probability for light absorption. Leaves of plants living in the

understory in dim light may have focusing mechanisms (convex epidermal cells) that focus the light

onto the chloroplasts. Trees have elaborate branching structures of leaves, which tend to maximize overall

light absorption by the plant. Plants competing for light in the understory may receive up to 50% of their

light as sunflecks—transient sun exposures—and can often rapidly ramp up PS and stomatal opening

during these brief events. Light reaching the understory is least depleted in the far red wavelengths compared to blue or red etc.

Many plants alter their leaf angles to track the position of the sun (solar

tracking), including alfalfa, cotton, soybean, lavatera, and lupine.

This is a blue light response, which is often controlled at the pulvinus found at the junction of the blade and the petiole,

and such leaves are called diaheliotropic. Such plants are often competing in short growing seasons.

Plants in deep shade often acclimate, but the plant (or at least the shade-adapted leaves) may not be able

to survive if the habitat becomes sunny, due to photoinhibition.

Here are general properties and tendencies of shade leaves compared to sun leaves:

• have more total chlorophyll per reaction center

• tend to be thinner, with thinner palisades

• have less rubisco and less xanthophyll (which is photoprotective)

• have higher ratio of PSI to PSII (3:1 compared to 2:1), or have more antenna chlorophyll in PSII. These

adaptations “enhance light absorption and energy transfer” to make better use of the relatively more

abundant far red light.

• have lower rates of respiration (“dark respiration”

• have lower maximum PS rates (saturation) that sun plants

.............................................................................................................................................

As for the relation Power to Efficency ,for leds...

The most efficient led dies are the 1 Watt chips..

The lower current,that drives a led ,the higher the efficiency,converting electricity into light!!!

Do not expect 3-5-10 Watt leds to be more efficient than 1 Watt led...

Instead, 10 x 1 Watt leds are far more powerful (and efficient) than 1 x 10 Watt led...

Plus ,the heat from multiple dies gets more easily dissipated ...

A 10 Watt led ,concentrates a lot of heat in a very small area...

Difficult to cool ,keep working efficiently and have a long operational(service ) life...

Probably,you save some money when buying...Nothing else...(Although ,asian 1 Watt leds cost less than .5$ ,per piece....)

Worth to give it try ,though....

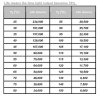

Specs....

Asian leds ,also have data sheets....

But they do not 'fall' exactly ,on the sheets specs...

At least,not all of them..(the leds..)...

..

Although,the asian led makers, have already developed

plenty of methods( e.x. thicker phosphor layer-more quantity of phosphor) to make their leds more 'uniform' ,

regarding spectra, & output power( better quality of mirror,silicone,protective lens & better dies,ect)

stardustsailor

Well-Known Member

Today,is the first day of 6th week on 12/12...(36th flowering day..)

From the very first day of reproductive phase (flowering) ,the plant was illuminated from 44 Watts of led lights...

(Spectra : 8 x cool white,12 x warm white,4 x red 630nm )

...

From day 35 (yesterday) a third 22 Watt panel was added...

( 2 x 6 cool,2 neutral,12 warm,4 red 630 & 1x 8 cool,12 warm,4 red 630nm )

So,until harvest 66 Watts of leds ,are going to ' finish' the 'job'....

Looking good..Despite the really bad vegging,awful chlorinated tap water ( pH :6.4 EC: 1.4 !!! ) & too much Polysorbate 20,that affected most of the leaves.....

From the very first day of reproductive phase (flowering) ,the plant was illuminated from 44 Watts of led lights...

(Spectra : 8 x cool white,12 x warm white,4 x red 630nm )

...

From day 35 (yesterday) a third 22 Watt panel was added...

( 2 x 6 cool,2 neutral,12 warm,4 red 630 & 1x 8 cool,12 warm,4 red 630nm )

So,until harvest 66 Watts of leds ,are going to ' finish' the 'job'....

Looking good..Despite the really bad vegging,awful chlorinated tap water ( pH :6.4 EC: 1.4 !!! ) & too much Polysorbate 20,that affected most of the leaves.....

stardustsailor

Well-Known Member

Well ...

You still need a heatsink and a CC driver to operate it...

All whites at 6500K...

Not bad for clone/seedling illumination...

And ,indeed,at a reasonable price...

(Astir's MCPCB ,together with 24 leds soldered ,has a retail price of about 20€ ...-26 $ -..

With a Spectra of : 4x Cool 7000-9000° K,4x Neutral 4500-6500°K ,12x Warm 2500-3500° K & 4x red 630 nm ...

All white light leds are custom ordered & manufactured , from Shenzhen Powered Optoelectronics Co. , with Bridgelux chip at 45 x 45 mil ,reds have Epistar chip..)

You still need a heatsink and a CC driver to operate it...

All whites at 6500K...

Not bad for clone/seedling illumination...

And ,indeed,at a reasonable price...

(Astir's MCPCB ,together with 24 leds soldered ,has a retail price of about 20€ ...-26 $ -..

With a Spectra of : 4x Cool 7000-9000° K,4x Neutral 4500-6500°K ,12x Warm 2500-3500° K & 4x red 630 nm ...

All white light leds are custom ordered & manufactured , from Shenzhen Powered Optoelectronics Co. , with Bridgelux chip at 45 x 45 mil ,reds have Epistar chip..)

stardustsailor

Well-Known Member

Meaning ?I hope to God your putting a daisy chain feature on these

Bluezdude

Well-Known Member

Aye, it's gonna be something like what you see in the picture. That's just the prototype, will be custom made to the size people want (for 2,3,4 panels etc)I hope to God your putting a daisy chain feature on these

It'll also look nicer

Bluezdude

Well-Known Member

That it does, where's the heatsink tho? What'll happen if one fan fails? The ones we're using have a huge heatsink, which then again means they're quite heavy.This Light fly by itself , only a Powercord is needed.

View attachment 2336830

and a bit nice blow of Air for the ladys included

About the hanging part tho, things will definitely improve, the flexibility however will not get lost. The final hanging case will be more sturdy and neater.

stardustsailor

Well-Known Member

Keeping the leds running cool is ,probably,one of the major problems ,a led panel designer has to solve...

The easiest (and cheapest..) way ,is to rely on active -cooling.

Active cooling ,means that extra energy is wasted to keep the temperature at a certain level or range...

Active cooling ,usually,incorporates some kind of mechanism(s)...For example water-cooling needs a water pump ,working...

Air-cooling ,needs a fan (or fans ),working...

Lets set aside ,small ' inconveniences ' that normally will occur,like 'wasting' an amount of energy (=money),extra power supply or generated noise....

Let's concentrate at the fact ,how safe and trouble-free ,they really are....

Let's assume,that you are not near the growing site...(You are currently shopping with your loved one,for example...)

The fan ,that keeps things cool,decides that this is a good day for it ,to die...

Hoka hey !

Question #1: How long ,it will take ,before the leds suffer from permanent damage ?

Spoiler: Not to long...Less than 10' ....

Question #2:How ,on earth,one spends a small fortune on high quality ,renowed brand, leds and then ,just let their fate ,in the ..wings of cheap fans ?

Question #3: Why spend time ,cleaning,lubricating and checking a fan ?

I'm just asking these questions....

'Cause I know a far better way to deal with cooling...

...

No, it's not cheap or lightweight ( I'm not flying my Phoenix wingsuit ,to care about weight)...

It's called passive cooling....

And yes ,it needs ('soft' alloy) aluminium (or for Hi-enders ,copper).Lots of it !

But,in turn,you can sleep or go shopping and being rest assured about the safety ,efficiency and longevity of your leds....

But still...

It's just another matter of wise choice....

One is always free to decide...

The easiest (and cheapest..) way ,is to rely on active -cooling.

Active cooling ,means that extra energy is wasted to keep the temperature at a certain level or range...

Active cooling ,usually,incorporates some kind of mechanism(s)...For example water-cooling needs a water pump ,working...

Air-cooling ,needs a fan (or fans ),working...

Lets set aside ,small ' inconveniences ' that normally will occur,like 'wasting' an amount of energy (=money),extra power supply or generated noise....

Let's concentrate at the fact ,how safe and trouble-free ,they really are....

Let's assume,that you are not near the growing site...(You are currently shopping with your loved one,for example...)

The fan ,that keeps things cool,decides that this is a good day for it ,to die...

Hoka hey !

Question #1: How long ,it will take ,before the leds suffer from permanent damage ?

Spoiler: Not to long...Less than 10' ....

Question #2:How ,on earth,one spends a small fortune on high quality ,renowed brand, leds and then ,just let their fate ,in the ..wings of cheap fans ?

Question #3: Why spend time ,cleaning,lubricating and checking a fan ?

I'm just asking these questions....

'Cause I know a far better way to deal with cooling...

...

No, it's not cheap or lightweight ( I'm not flying my Phoenix wingsuit ,to care about weight)...

It's called passive cooling....

And yes ,it needs ('soft' alloy) aluminium (or for Hi-enders ,copper).Lots of it !

But,in turn,you can sleep or go shopping and being rest assured about the safety ,efficiency and longevity of your leds....

But still...

It's just another matter of wise choice....

One is always free to decide...

Jahulath

Member

Wise is the word friend but sadly also expensive  those ali extrusions are proper expensive for what you get, anyone would have thought it was difficult to smelt and extrude an already expensive metal at a mere 500c hehe.

those ali extrusions are proper expensive for what you get, anyone would have thought it was difficult to smelt and extrude an already expensive metal at a mere 500c hehe.

I'm getting to think that there may be more one can do. Looking in old computers you will see all manner of systems for making semi active cooling, the most prevalent one is using ducting to the main exhaust fan from the heat sink, a pretty stable system (that uses kit you already have installed) but still active I guess. Are there ways to use a bit of physics? Logic would suggest that a chimney could be installed to aid airflow but I may just be baked.

You have heat anyway and that means you have convection, the really shit 2 second sketch shows the air being pulled across the heat sink by the warm air as it rises. If this was made out of 2mm Ali and set to actually rest on the heatsink you would get an even better draw from the chimney effect. Never going to work in a PC but we have the benefit of being horizontal! An idea or a "pipe dream"? (I still love the way that phrase is used in every day life and yet as far as I know it refers directly to smoking Opium lmao)

I'm getting to think that there may be more one can do. Looking in old computers you will see all manner of systems for making semi active cooling, the most prevalent one is using ducting to the main exhaust fan from the heat sink, a pretty stable system (that uses kit you already have installed) but still active I guess. Are there ways to use a bit of physics? Logic would suggest that a chimney could be installed to aid airflow but I may just be baked.

You have heat anyway and that means you have convection, the really shit 2 second sketch shows the air being pulled across the heat sink by the warm air as it rises. If this was made out of 2mm Ali and set to actually rest on the heatsink you would get an even better draw from the chimney effect. Never going to work in a PC but we have the benefit of being horizontal! An idea or a "pipe dream"? (I still love the way that phrase is used in every day life and yet as far as I know it refers directly to smoking Opium lmao)

stardustsailor

Well-Known Member

Leds are a " newbie " technology to growing plants...

A lot of research is needed,still...

And a clear mind....

I will ask another question....

But before that ,read this :

Forget the spectrum....

Let's talk about light power distribution....

If one has one 400 Watt HPS and the (hypothetic) option of 400 x 1 Watt small HPS lamps....

Which of these two options ,is by far ,the best for illuminating a plant ?

In the single-point light option,don't forget the 'zones'...The no-no bleaching top zone,the 'sweet spot' zone and ,finally, the "shade" zone....

Let me rephrase my question....

How clever or stupid is,for one,to use multiple small lights ,just to construct a single-point light ,for plant illuminating purposes ?

Personally,I don't think NASA spoke ,about the idea of "surrounding" light (intracanopy) ,just by luck or coincidence....

Yes,it might be convenient for handling,shipping,hanging,ect....

But ..

Is it efficient ?

.....

Spoiler:

No.

By all means,no!

And that is just the tip of the iceberg...

When we reach to the right choise of leds (Whites or actinic red,amber,green & blues ? ) ,

that's the 'point' ,where the big lies(or bull... ),are being said & written all over ,again and again....

A lot of research is needed,still...

And a clear mind....

I will ask another question....

But before that ,read this :

Now...There is a question. Is it necessary to prepare optimal light conditions for the photosynthesis of all leaves on the plant or not? What way is it determined? The correct decision on spectral composition of light depends very much on certain morphological characteristics of plants. There is a dependance upon the distribution of fruits along a stem (Tikhomirov, 1990). For example, cucumber has equal distribution of fruits along the stem. There every leaf supplies assimilate to its fruit(or flower). In this connection cucumber leaves at all layers must be provided with optimal light conditions. This requires a large portion of green rays in PAR (about 40%). Red rays in PAR (about 40%) provide high level of photosynthesis of upper leaves. Green rays penetrate into middle and lower leaves of plants. Blue rays have regulatory function, but its part in PAR is not very big (about 20%) (Tikhomirov, 1989).

We have another situation, where fruits of a plant concentrate in the upper part of the stem. Classical example is wheat. The ear of wheat is supplied with assimilates, primarily from the upper leaves. With this crop, PAR must have approximately 60-70% red rays (Tikhomirov, 1990). We've obtained data on specific reactions of plants for the spectral composition of PAR. It's particularly important during plant development processes. According to this point of view plants may be divided into two groups (Tikhomirov et al., 1991)

http://biology.mcgill.ca/Phytotron/LightWkshp1994/1.3 Tikhomirov/Tikhomirov text.htm

Forget the spectrum....

Let's talk about light power distribution....

If one has one 400 Watt HPS and the (hypothetic) option of 400 x 1 Watt small HPS lamps....

Which of these two options ,is by far ,the best for illuminating a plant ?

In the single-point light option,don't forget the 'zones'...The no-no bleaching top zone,the 'sweet spot' zone and ,finally, the "shade" zone....

Let me rephrase my question....

How clever or stupid is,for one,to use multiple small lights ,just to construct a single-point light ,for plant illuminating purposes ?

Personally,I don't think NASA spoke ,about the idea of "surrounding" light (intracanopy) ,just by luck or coincidence....

Yes,it might be convenient for handling,shipping,hanging,ect....

But ..

Is it efficient ?

.....

Spoiler:

No.

By all means,no!

And that is just the tip of the iceberg...

When we reach to the right choise of leds (Whites or actinic red,amber,green & blues ? ) ,

that's the 'point' ,where the big lies(or bull... ),are being said & written all over ,again and again....

guod

Well-Known Member

1. 100% fan-power (0.9 W)Question #1: How long ,it will take ,before the leds suffer from permanent damage ?

Spoiler: Not to long...Less than 10' ....

Temperature for all Leds(Dye-Temp) are below 40°C this means also that the light-Output is > 90%

at higher room-temperature up to 30°C only the red leds(630 nm) goes down to 85 - 80%

2. 75% fan-power (see it as an old dusty fan)

no dramatical change here, plus 2-3°K for the leds.

for this test i change the 27 Ohm to 56 Ohm.

3. defect fan (worst case)

heatsink goes up to 50°C

the temp. of the leds is near 70°C (up to 85°C will be no problem for Leds)

the output for the 630 nm leds is now at 65%. all other leds are over 85% (little shift in the spectrum)

as you see the modul works w/o a fan and we get enough time to fix the fan.

Me.Question #2:How ,on earth,one spends a small fortune on high quality ,renowed brand, leds and then ,just let their fate ,in the ..wings of cheap fans ?

I clean my Tools after every Grow, too much for you?Question #3: Why spend time ,cleaning,lubricating and checking a fan ?

lubricating !!! .......Scotty beam me up...

post 15 from here

the MCPCB which is in direkt contact with the LEDS and on the other side with the Heatsink can go cooler than the Heatsink, not bad dude!With ambient temp of 34°C ,the heatsink had a temp of 38° C on its fin base...( cycle 24/0 !! )

Also the front side of the MCPCB was at 38-37° C ,also...

stardustsailor

Well-Known Member

Well,yes....Wise is the word friend but sadly also expensivethose ali extrusions are proper expensive for what you get, anyone would have thought it was difficult to smelt and extrude an already expensive metal at a mere 500c hehe.

I'm getting to think that there may be more one can do. Looking in old computers you will see all manner of systems for making semi active cooling, the most prevalent one is using ducting to the main exhaust fan from the heat sink, a pretty stable system (that uses kit you already have installed) but still active I guess. Are there ways to use a bit of physics? Logic would suggest that a chimney could be installed to aid airflow but I may just be baked.

View attachment 2336944

You have heat anyway and that means you have convection, the really shit 2 second sketch shows the air being pulled across the heat sink by the warm air as it rises. If this was made out of 2mm Ali and set to actually rest on the heatsink you would get an even better draw from the chimney effect. Never going to work in a PC but we have the benefit of being horizontal! An idea or a "pipe dream"? (I still love the way that phrase is used in every day life and yet as far as I know it refers directly to smoking Opium lmao)

Such a massive heatsink ,like the one Astir Co.,is using ,it is quite expensive...And heavy ( almost 4 lbrs ,each ) ...

But it does the job ,perfectly....

You can try copper heatpipes...

Although,that is also an expensive option...

You know what ?

One cannot have it all....

Cheap,effective,lightweight,service-free,trouble-free,ect....

And that's why cooling the leds is one of the major problems ,a led panel desinger has to solve...

And all the options have pros 'n' cons...

Not an easy one...

stardustsailor

Well-Known Member

1. 100% fan-power (0.9 W)

Temperature for all Leds(Dye-Temp) are below 40°C this means also that the light-Output is > 90%

at higher room-temperature up to 30°C only the red leds(630 nm) goes down to 85 - 80%

2. 75% fan-power (see it as an old dusty fan)

no dramatical change here, plus 2-3°K for the leds.

for this test i change the 27 Ohm to 56 Ohm.

3. defect fan (worst case)

heatsink goes up to 50°C

the temp. of the leds is near 70°C (up to 85°C will be no problem for Leds)

the output for the 630 nm leds is now at 65%. all other leds are over 85% (little shift in the spectrum)

as you see the modul works w/o a fan and we get enough time to fix the fan.

Me.

I clean my Tools after every Grow, too much for you?

lubricating !!! .......Scotty beam me up...

post 15 from here

the MCPCB which is in direkt contact with the LEDS and on the other side with the Heatsink can go cooler than the Heatsink, not bad dude!

How exactly you measured the Tj ?

Did you just, add up the thermal resistances ?

How many Watts is your panel ?

85°C is no problem ? Are you sure ?

...

...

"...the MCPCB which is in direkt contact with the LEDS and on the other side with the Heatsink can go cooler than the Heatsink, not bad dude!..."

Yes,it's possible....

If the heatsink has big enough values of ,both,thermal conductance and thermal transmittance ,

accompanied with a low value of thermal capacitance..

It's all, a matter of aluminium alloy used,number-thickness-height of fins and thickness of heatsink base...

After all ,the mass/surface area of heatsink surpass the mass/surface area of the ,1mm thick, mcpcb...It 'sucks' all of its heat.....

Simple Thermodynamics...

I can shoot some photos tomorrow ,after 6 hours of operation with a K-type sensor ,attached to heatsink and PCB...

Just to prove it to you ...

It's your choice to use fans...

Mine,isn't...

Why you get so upset ?

I say my opinion ,you say yours..

But,facts are facts....And it goes for both of us...

And if it was the time limit ( 10 ' ) that upset you ..Ok ,I can make it 24 hours...

Or as much ,as you would like....

Will you leave the leds working without the fans for 24 hours ?

Since that,even at 85° C,there isn't a problem,as you claim....

And moreover...

Why you think that my post was an answer to yours ?

I'm referring generally to cooling...

It might be possible,that what I say may not apply,specially, for your panel...

(For many different reasons...)

What do you think instead,about a $.$$$ led panel of some hundred Watts,which has plenty of fans ,enclosed on a metal box ?

What happens there ,if a fan fails ?

You think that ,they will happen the same things ,as of the three cases ,you analysed ?

Let's say with a 400 Watt or 600 Watt led panel....

If a fan stops working there ,everything is going to be just ok ?

....

We are not reviewing or testing,exclusively ,your panel...

Save your bad mood,in case of fried leds...

For now ,keep growing,rolling & smiling...

P.S.

Don't know, up there on Enterprise ,what kind of fans ,you people, are using...

But here,on our planet,fans blow dust,hair and other debris ,along with air...

So,any moving parts,get dirty & dry ,pretty easy....

Since they are the cheap ones,they do not have a decent ball-bearing on axle.

So(again),either we often clean & lubricate the fans(...its a bit tricky to do..)

or we leave them as they are and

when they start to make weird noises & sounds,if we ever notice(hear),

we just throw them away and replace them with new ones,before they fail....

...

My greetings to Captain Kirk & Mr.Spock ...

PSUAGRO.

Well-Known Member

Can you elaborate why you think that 660nm is not beneficial to C3 plants......I graduated some time ago but I do remember that "generally" chlorophyll A peaks at 660 and B peaks at 640......and are all your leds driven at 350ma(1watters right?)..... so since red wavelengths carry way less power that blue why load up on white leds vers red instead of the opposite?..............junction temps vary by the manufacturer, but 85c IMO is too hot. Yeah passive cooling is expensive, but your using cheap bridgelux(ok-not great)/epistar(suck) leds/cheap driver and board/ with an expensive heatsink?I dont get it, why not use quality parts throughout like this american company http://www.rhinogrow.com/ .........good luck on your venture

but I do remember that "generally" chlorophyll A peaks at 660 and B peaks at 640......and are all your leds driven at 350ma(1watters right?)..... so since red wavelengths carry way less power that blue why load up on white leds vers red instead of the opposite?..............junction temps vary by the manufacturer, but 85c IMO is too hot. Yeah passive cooling is expensive, but your using cheap bridgelux(ok-not great)/epistar(suck) leds/cheap driver and board/ with an expensive heatsink?I dont get it, why not use quality parts throughout like this american company http://www.rhinogrow.com/ .........good luck on your venture

edit...yes 1 watt leds are more efficient than 3,5,10 etc. but your penetration will be much lower(i know you suggest scrog/sog for these panels) but sometimes phenotypes emerge that require larger vertical space, so a dimmable driver paired with high wattage leds will give you the best flexibility/longevity for indoor grows IMO.......

edit...yes 1 watt leds are more efficient than 3,5,10 etc. but your penetration will be much lower(i know you suggest scrog/sog for these panels) but sometimes phenotypes emerge that require larger vertical space, so a dimmable driver paired with high wattage leds will give you the best flexibility/longevity for indoor grows IMO.......

stardustsailor

Well-Known Member

Well,for starters C3 plants have more ChB in general...Can you elaborate why you think that 660nm is not beneficial to C3 plants......I graduated some time agobut I do remember that chlorophyll A peaks at 660 and B peaks at 640......and are all your leds driven at 350ma(1watters right?)..... so since red wavelengths carry way less power that blue why load up on white leds vers red instead of the opposite?..............junction temps vary by the manufacturer, but 85c IMO is too hot. Yeah passive cooling is expensive, but your using cheap bridgelux(ok-not great)/epistar(suck) leds with an expensive heatsink?i dont get it, why not completely use quality parts throughout like this american company http://www.rhinogrow.com/ .........good luck on your venture

edit...yes 1 watt leds are more efficient than 3,5,10 etc. but your penetration will be much lower(i know you suggest scrog/sog for these panels) but sometimes phenotypes emerge that require larger vertical space, so a dimmable driver paired with high wattage leds will give you the best flexibility/longevity for indoor grows IMO.......

ChA is a more 'tropical' photosynthetic pigment....

(Only, Equatorial areas have plenty of 650-680 nm in sunlight...Greater angle of sun..Less red photons absorbed by water in atmosphere)..

660 nm light in C3 plants ,mainly alter the phytochrome state from the "base " Pr to "active" Pfr...

Lots of Pfr.....

I have performed quite a bit of real-life experiments with 660nm leds....

Cactii seem to like it...

C3 plants ,no...In fact,not at all...

They adapt their leaves to "extreme sunlight conditions"..

Few ,small(reduced lamina surface area) and thick leaves is what you get with 660 nm reds...

Abnormal stem/petiole growth..Extensive internodal streching...

Closed stomata..Reduced respiration/transpiration..And reduced CO[SUB]2[/SUB] intake...

(You need elevated CO2 concentration in atm. )

Lower Photosynthetic Saturation Point (easy to get "CO[SUB]2[/SUB] limited " )

Increased photo-oxidation and photoinhibition

Long and flimsy buds....

And a reproductive state ,that lasts.... forever...

Difficult for flowers to reach maturity.If at all....

Do all these ring a bell ?

Tip:.....Tropical Sativas....

...

...

I believe that Warm White leds carry all the orange,red and NIR (far red ) a plant needs...With a nice 'nature-like' spectral curve...

And Warm Whites ,do not emit so much at blue region...

Way better than any actinic red...With higher efficiency and stability...

I just 'top' the 620-640 region with only a few reds....

And it seems that the whole concept is working ,better than,of what was expected....

...

...

Why cheap leds ?

1) They do the job.With a small difference( in power -25% max.) in comparison with high-quality leds.

The big difference is their price..(-1000% min.)

2) All leds, are subject to constant development.

Why pay a s..load of money on leds ,that next year will be 'old history' ?

Better ,save the money ,buy the new ones and constantly keep the panel upgraded ,to the latest tech...

3)They do not need reflow oven to be soldered.Easy to service/change.

Why cheap CC driver ?

-If it gets fried ,it is very cheap to buy a new one...

It's just a power supply.

Not a sophisticated,mono-block, high-end sound amplifier....

No need to be an expensive piece of electronics...

Why cheap PCB ?

Because they do the job just fine....

A plain 'sandwich' of thin aluminium plate,less than 100 microns epoxy insulation layer and copper 'lines'..What more to ask ?

And...

The heatsink stays there...For the full service life of panel(s)....

Never to be changed.

But its role,probably,is the most crucial one...

High quality leds with bad cooling or mediocre leds with ideal cooling ?

Which one works best,you think ?

Moreover....It's is not just 'parts' quality...

There are many other things to take under consideration such as overall efficiency,serviceability,ability of upgrading,retail price,ect....

Which add up to overall quality...

...

...

There is not such thing as 'penetration'....

Light is not a bullet.

"Penetration" stands ONLY for green/yellow light.That's the only wavelength that 'penetrates' a leaf.All other wls are absorbed by photosystems.

Moreover ,even if the statement "penetration" was true,it would have had a meaning for a single-point light source.Like HIDs for example.

These panels are designed to be placed ,wherever canopy needs illumination.

They are not a single-point light source.

A number of them,placed accordingly to canopy,work as 'one' surrounding light source.

Thus,penetration,even if it was standing true,has no meaning,since there is not a dark spot/area,with multiple light sources...

No matter of phenotypes,lateral or vertical growth..

...

...

1 Watt leds ,apart from being the most efficient,they produce small amounts of heat...

Easier to keep cool ,than 3,5,10,ect Watt leds...

...

...

Very good questions,BTW...