Will-In-China

Member

Guys,

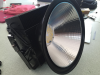

I'm looking for some help to source and select some better power connectors. As you can see from the image I mounted them to close to the entry hole and the cables look under undue stress, moving them further away from the entrance would help but there must be some better or best way of getting this right.

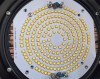

I also dont like the blue and brown colored cable should I use some black or white heat shrink?

Thanks in advance

Will

I'm looking for some help to source and select some better power connectors. As you can see from the image I mounted them to close to the entry hole and the cables look under undue stress, moving them further away from the entrance would help but there must be some better or best way of getting this right.

I also dont like the blue and brown colored cable should I use some black or white heat shrink?

Thanks in advance

Will

Last edited: